TABLE 21: ELECTRIC HEAT LIMIT CONTROL SETTING

VOLTAGE | kW | TEMPERATURE LIMIT SWITCH | Open Temp ºF | |

|

|

|

| |

| 5 | 1 | 140 | |

|

|

|

| |

| 7 | 1,3 | 140 | |

|

|

|

| |

| 10 | 1,2,3 | 140 | |

|

|

| ||

15 | 2,4,6 | 140 | ||

|

|

|

| |

| 20 | 1,2,3,4,5 | 140 | |

|

|

| ||

| 6 | 150 | ||

|

| |||

|

|

|

| |

| 30 | 1,2,3,4,5,6 | 150 | |

|

|

|

| |

| 5 | 1,2,3 | 140 | |

|

|

|

| |

| 7 | 1,2,3 | 140 | |

|

|

|

| |

| 10 | 1,2,3 | 150 | |

|

|

| ||

15 | 2,4,6 | 140 | ||

|

|

|

| |

| 20 | 1,2,3,4,5,6 | 150 | |

|

|

|

| |

| 30 | 1,3,5 | 160 | |

|

|

| ||

| 2,4,6 | 150 | ||

|

| |||

|

|

|

| |

| 7 | 2,4,6 | 140 | |

|

|

|

| |

| 10 | 2,4,6 | 140 | |

|

|

| ||

15 | 2,4,6 | 140 | ||

|

|

|

| |

| 20 | 3 | 160 | |

|

|

|

| |

| 30 | 3 | 150 | |

|

|

|

| |

| 10 | 2,4,6 | 140 | |

|

|

|

| |

15 | 2,4,6 | 140 | ||

|

|

| ||

20 | 5 | 160 | ||

| ||||

|

|

|

| |

| 30 | 5 | 150 | |

|

|

|

|

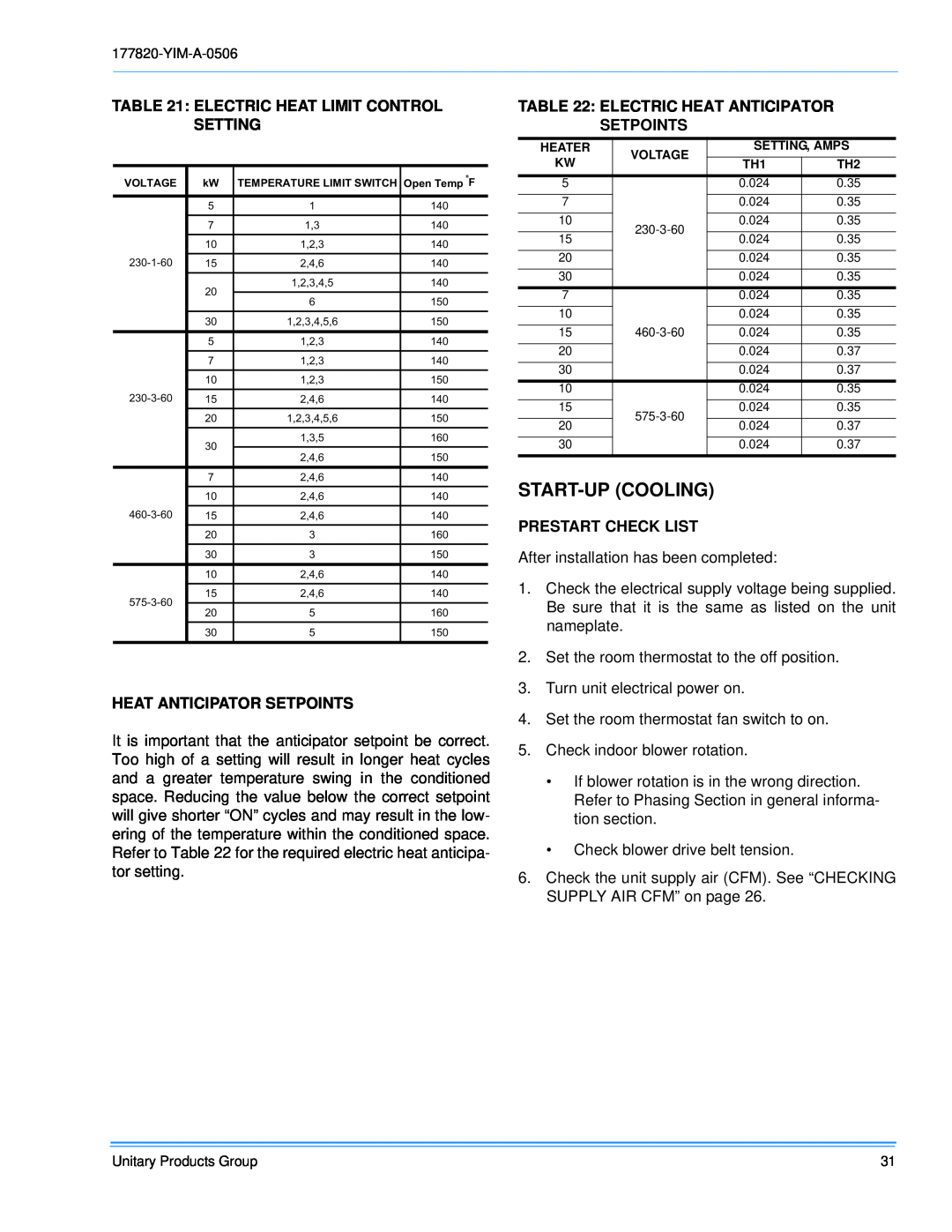

HEAT ANTICIPATOR SETPOINTS

It is important that the anticipator setpoint be correct. Too high of a setting will result in longer heat cycles and a greater temperature swing in the conditioned space. Reducing the value below the correct setpoint will give shorter “ON” cycles and may result in the low- ering of the temperature within the conditioned space. Refer to Table 22 for the required electric heat anticipa- tor setting.

TABLE 22: ELECTRIC HEAT ANTICIPATOR SETPOINTS

HEATER | VOLTAGE | SETTING, AMPS | ||

KW | TH1 | TH2 | ||

| ||||

5 |

| 0.024 | 0.35 | |

7 |

| 0.024 | 0.35 | |

10 | 0.024 | 0.35 | ||

15 | 0.024 | 0.35 | ||

| ||||

20 |

| 0.024 | 0.35 | |

30 |

| 0.024 | 0.35 | |

7 |

| 0.024 | 0.35 | |

10 |

| 0.024 | 0.35 | |

15 | 0.024 | 0.35 | ||

20 |

| 0.024 | 0.37 | |

30 |

| 0.024 | 0.37 | |

10 |

| 0.024 | 0.35 | |

15 | 0.024 | 0.35 | ||

20 | 0.024 | 0.37 | ||

| ||||

30 |

| 0.024 | 0.37 | |

START-UP (COOLING)

PRESTART CHECK LIST

After installation has been completed:

1.Check the electrical supply voltage being supplied. Be sure that it is the same as listed on the unit nameplate.

2.Set the room thermostat to the off position.

3.Turn unit electrical power on.

4.Set the room thermostat fan switch to on.

5.Check indoor blower rotation.

•If blower rotation is in the wrong direction. Refer to Phasing Section in general informa- tion section.

•Check blower drive belt tension.

6.Check the unit supply air (CFM). See “CHECKING SUPPLY AIR CFM” on page 26.

Unitary Products Group | 31 |