DUCTWORK

Ductwork should be designed and sized according to the methods in Manual Q of the Air Conditioning Con- tractors of America (ACCA).

A closed return duct system shall be used. This shall not preclude use of economizers or outdoor fresh air intake. The supply and return air duct connections at the unit should be made with flexible joints to minimize noise.

The supply and return air duct systems should be designed for the CFM and static requirements of the job. They should NOT be sized to match the dimen- sions of the duct connections on the unit.

When fastening ductwork to side duct flanges on unit, insert screws through duct flanges only. DO NOT insert screws through casing. Outdoor ductwork must be insulated and waterproofed.

Refer to Figures 7 and 10 for information concerning side and bottom supply and return air duct openings.

CONDENSATE DRAIN

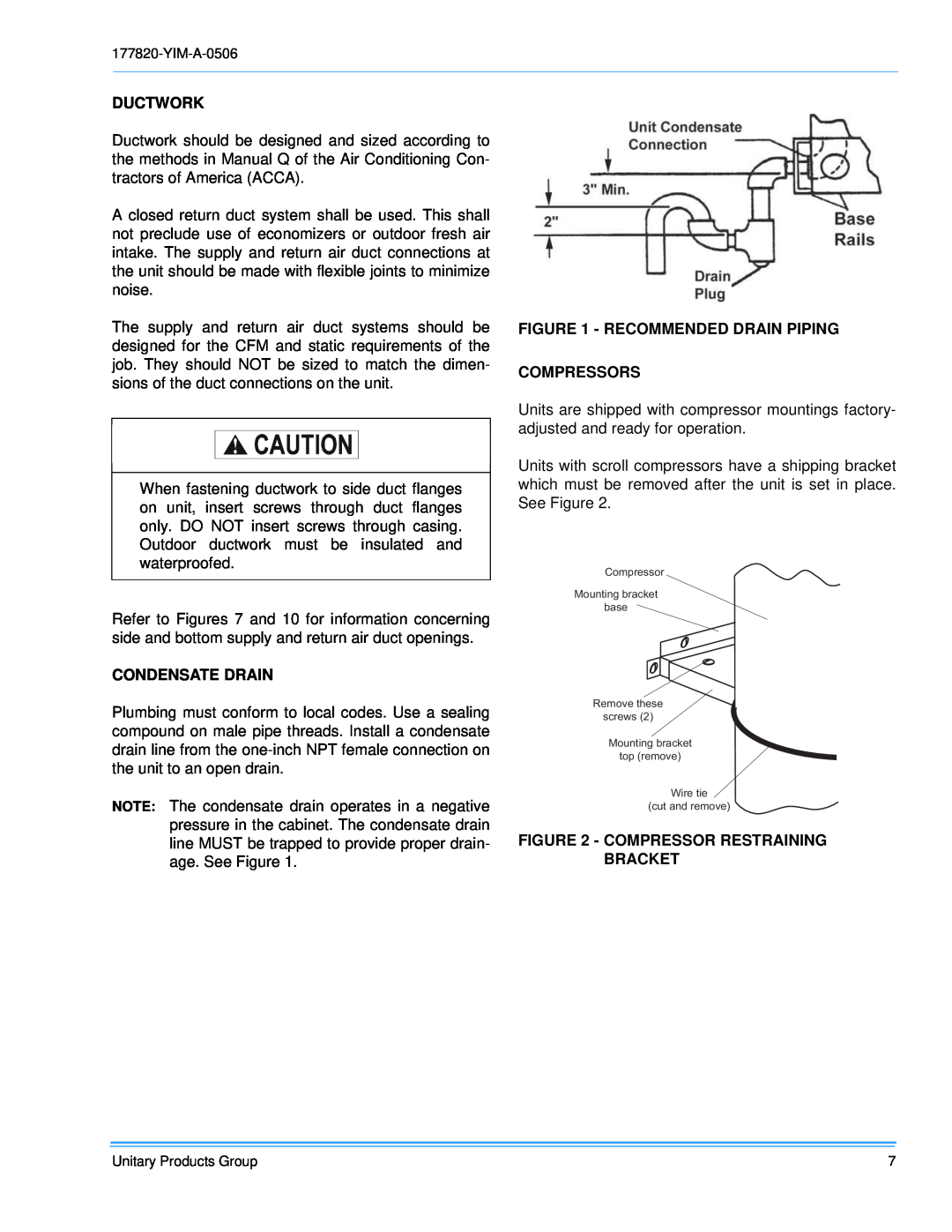

Plumbing must conform to local codes. Use a sealing compound on male pipe threads. Install a condensate drain line from the

NOTE: The condensate drain operates in a negative pressure in the cabinet. The condensate drain line MUST be trapped to provide proper drain- age. See Figure 1.

FIGURE 1 - RECOMMENDED DRAIN PIPING

COMPRESSORS

Units are shipped with compressor mountings factory- adjusted and ready for operation.

Units with scroll compressors have a shipping bracket which must be removed after the unit is set in place. See Figure 2.

Compressor

Mounting bracket

base

Remove these

screws (2)

Mounting bracket

top (remove)

Wire tie

(cut and remove)

FIGURE 2 - COMPRESSOR RESTRAINING BRACKET

Unitary Products Group | 7 |