FORM

Application Data

GENERAL

The Eco2 air conditioning units are designed for outdoor installation. When selecting a site for installation, be guided by the following conditions:

•Unit must be installed on a level surface.

•For the outdoor location of the unit, select a place having a minimum sun exposure and an adequate supply of fresh air for the condenser.

•Also avoid locations beneath windows or between structures.

•Optional condenser coil protection should be used for seashore locations or other harsh environ- ments.

•The unit should be installed on a roof that is structur- ally strong enough to support the weight of the unit with a minimum of deflection. It is recommended that the unit(s) be installed not more than 15 feet from a main support beam to provide proper structural support and to minimize the transmission of sound and vibration. Ideally, the center of gravity should be located over a structural support or building column.

•Location of unit(s) should also be away from build- ing flue stacks or exhaust ventilators to prevent possible reintroduction of contaminated air through the outside air intakes.

•Be sure the supporting structures will not obstruct the duct, gas or wiring connections.

•Proper service clearance space of

LOCATION

Of the many factors that can effect the location of equipment, some of the most important to consider are Structural, Acoustical and Service clearances. Proper attention should be made at the design stage to ensure proper structural support. In cases where equipment is being replaced, be aware of building design to insure support is adequate for the application.

The next most important consideration in applying roof top equipment is that of sound from the equipment. Special care should be made to keep the roof top unit away from sound sensitive areas such as conference rooms, auditoriums and executive offices and any other room that may have potential for tenant occupancy. Pos- sible locations could be above hallways, mechanical or utility rooms.

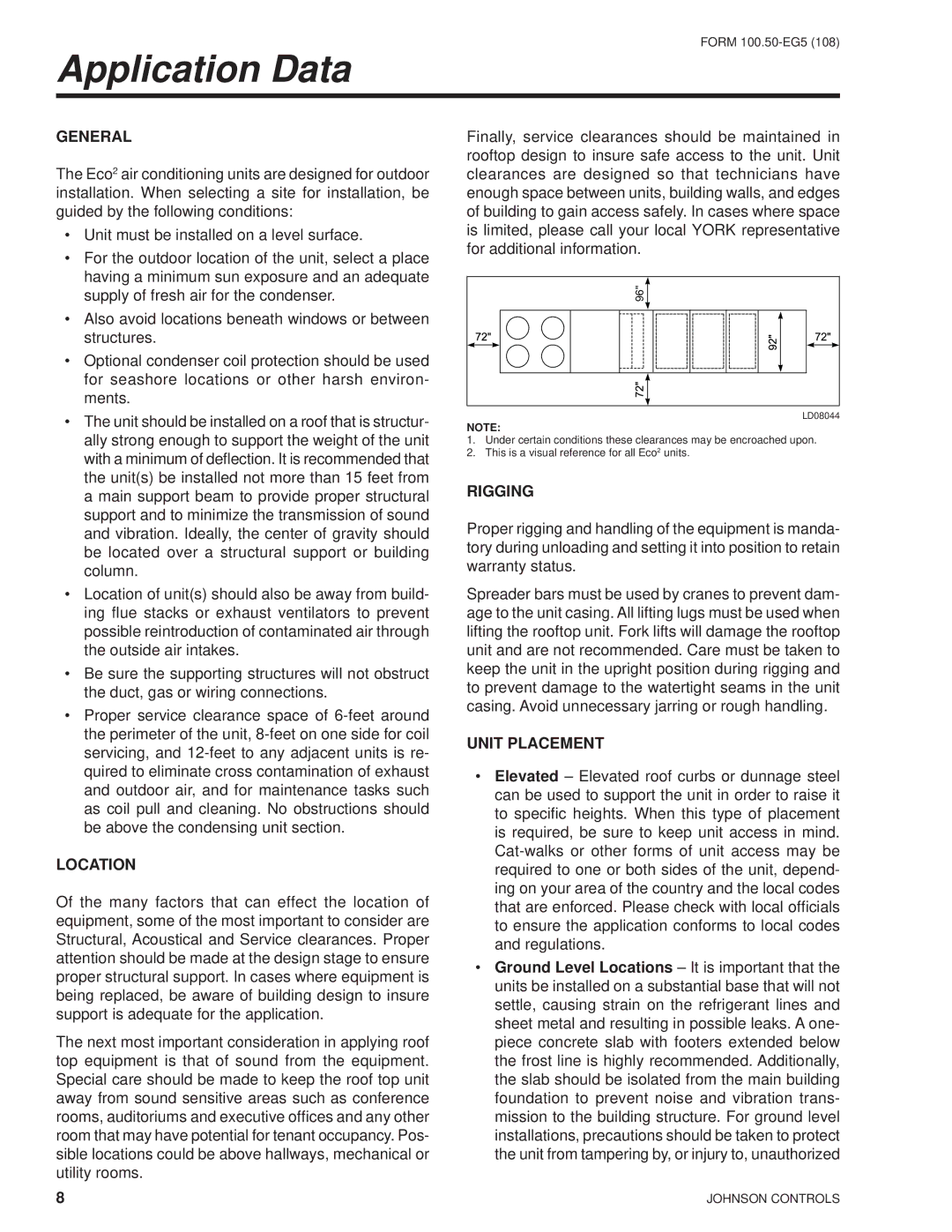

Finally, service clearances should be maintained in rooftop design to insure safe access to the unit. Unit clearances are designed so that technicians have enough space between units, building walls, and edges of building to gain access safely. In cases where space is limited, please call your local YORK representative for additional information.

96" |

LD08044 |

NOTE: |

1.Under certain conditions these clearances may be encroached upon.

2.This is a visual reference for all Eco2 units.

RIGGING

Proper rigging and handling of the equipment is manda- tory during unloading and setting it into position to retain warranty status.

Spreader bars must be used by cranes to prevent dam- age to the unit casing. All lifting lugs must be used when lifting the rooftop unit. Fork lifts will damage the rooftop unit and are not recommended. Care must be taken to keep the unit in the upright position during rigging and to prevent damage to the watertight seams in the unit casing. Avoid unnecessary jarring or rough handling.

UNIT PLACEMENT

•Elevated – Elevated roof curbs or dunnage steel can be used to support the unit in order to raise it to specific heights. When this type of placement is required, be sure to keep unit access in mind.

•Ground Level Locations – It is important that the units be installed on a substantial base that will not settle, causing strain on the refrigerant lines and sheet metal and resulting in possible leaks. A one- piece concrete slab with footers extended below the frost line is highly recommended. Additionally, the slab should be isolated from the main building foundation to prevent noise and vibration trans- mission to the building structure. For ground level installations, precautions should be taken to protect the unit from tampering by, or injury to, unauthorized

8 | JOHNSON CONTROLS |