CBM-270 User’s Manual

3.OUTER APPEARANCE AND COMPONENT PARTS

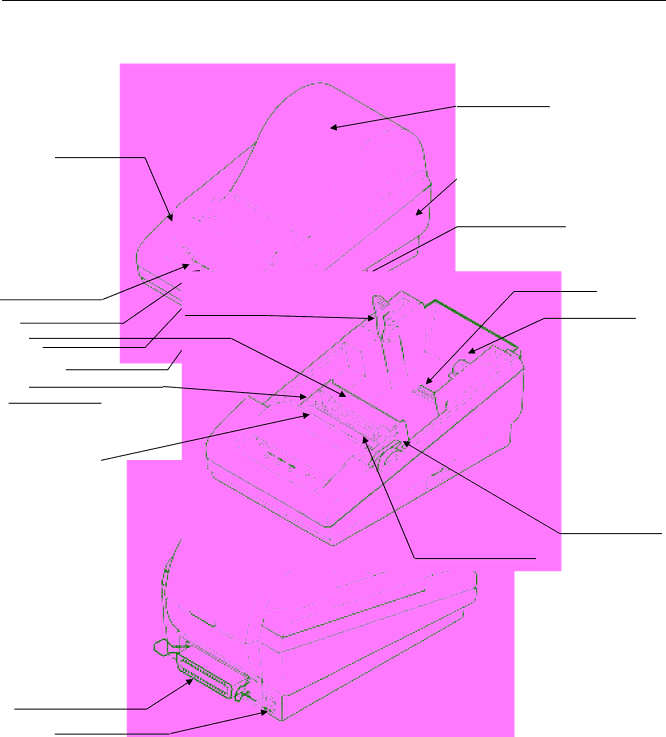

Upper Cover

POWER Lamp

ERROR Lamp

FEED Switch

PNE Sensor

LabelPAPERDetectionLampSensor Printer Mechanism

(L and M spec. Only)

Paper Cutter

(1) POWER switch

Turns on/off the power for the printer body. Interface Connector

(2) POWER lamp Power Connector

Illuminated when the power switch is turned on.

Printer Cover

Bottom Cover

POWER Switch

DIP Switch

Paper Holder

Platen Roller Unit

(3)ERROR lamp

Illuminated at the time of a

(4)PAPER lamp

Illuminated when the paper is running out (when there is little paper left), and blinks when a label paper cut is specified.

(5)FEED switch