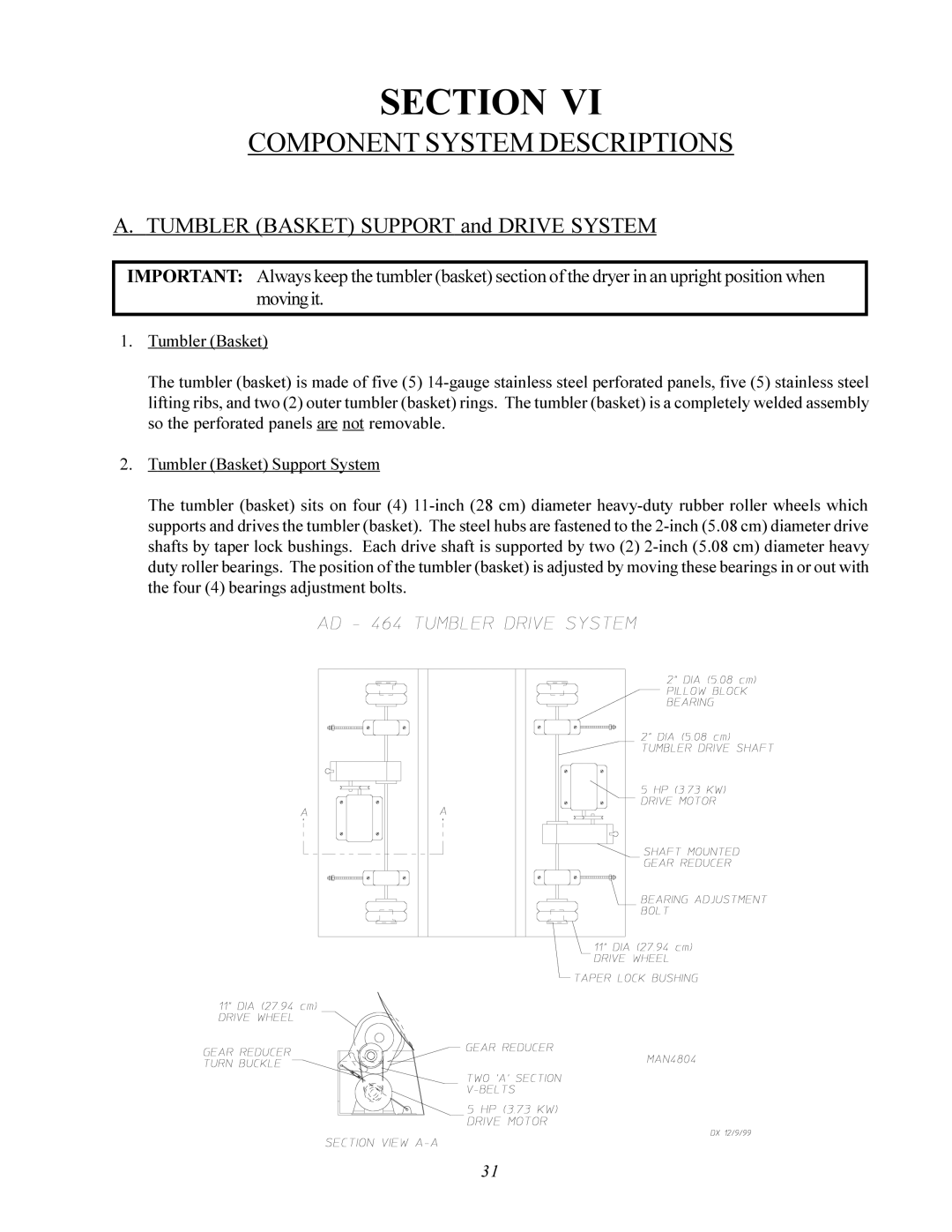

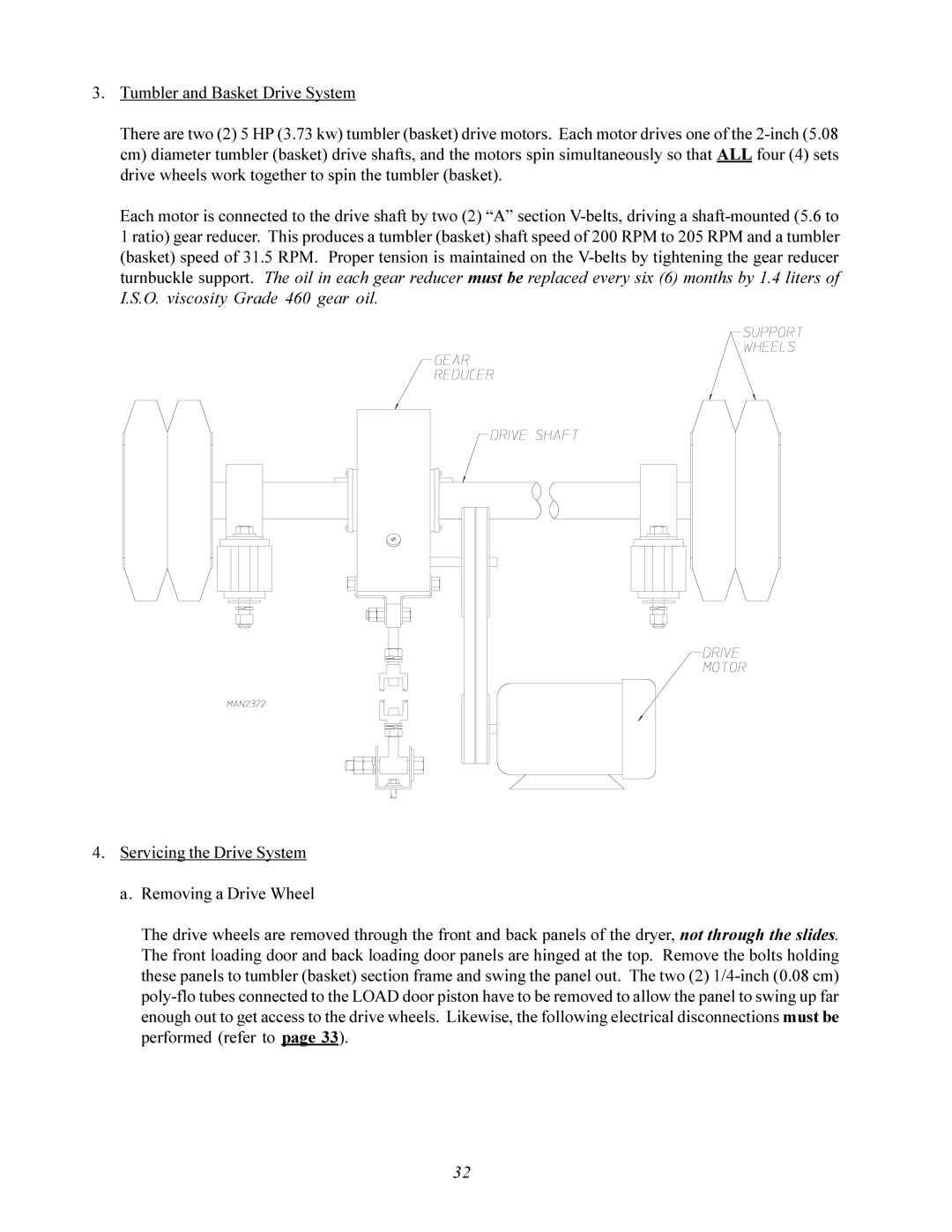

3.Tumbler and Basket Drive System

There are two (2) 5 HP (3.73 kw) tumbler (basket) drive motors. Each motor drives one of the 2-inch (5.08 cm) diameter tumbler (basket) drive shafts, and the motors spin simultaneously so that ALL four (4) sets drive wheels work together to spin the tumbler (basket).

Each motor is connected to the drive shaft by two (2) “A” section V-belts, driving a shaft-mounted (5.6 to 1 ratio) gear reducer. This produces a tumbler (basket) shaft speed of 200 RPM to 205 RPM and a tumbler (basket) speed of 31.5 RPM. Proper tension is maintained on the V-belts by tightening the gear reducer turnbuckle support. The oil in each gear reducer must be replaced every six (6) months by 1.4 liters of I.S.O. viscosity Grade 460 gear oil.

4.Servicing the Drive System

a.Removing a Drive Wheel

The drive wheels are removed through the front and back panels of the dryer, not through the slides. The front loading door and back loading door panels are hinged at the top. Remove the bolts holding these panels to tumbler (basket) section frame and swing the panel out. The two (2) 1/4-inch (0.08 cm) poly-flo tubes connected to the LOAD door piston have to be removed to allow the panel to swing up far enough out to get access to the drive wheels. Likewise, the following electrical disconnections must be performed (refer to page 33).