C. COMPRESSED AIR SYSTEM

The compressed air system of the

1.Air Pistons

The pistons are actuated by solenoid and flow control valves that are under computer control. The pneumatic pistons are used to:

•Tilt the dryer for loading and unloading.

•Open and close LOAD and UNLOAD doors.

•Operate heat reclaimer.

•Operate the cool down damper and the intake air damper.

2.Filter Regulator Assembly

The compressed air supply to the dryer is connected into the

The Filter Regulator assembly performs two (2) functions;

a.The filter removes most solids and liquid particles from the compressed air stream and traps them in its bowl where this waste can be readily removed through the drain valve at the bottom of the bowl.

The filter bowl should be cleaned monthly.

b.The regulator will maintain a nearly constant outlet air pressure of 80 PSI (552 kPa) so that the dryer’s air pistons will function normally despite upstream air pressure variation.

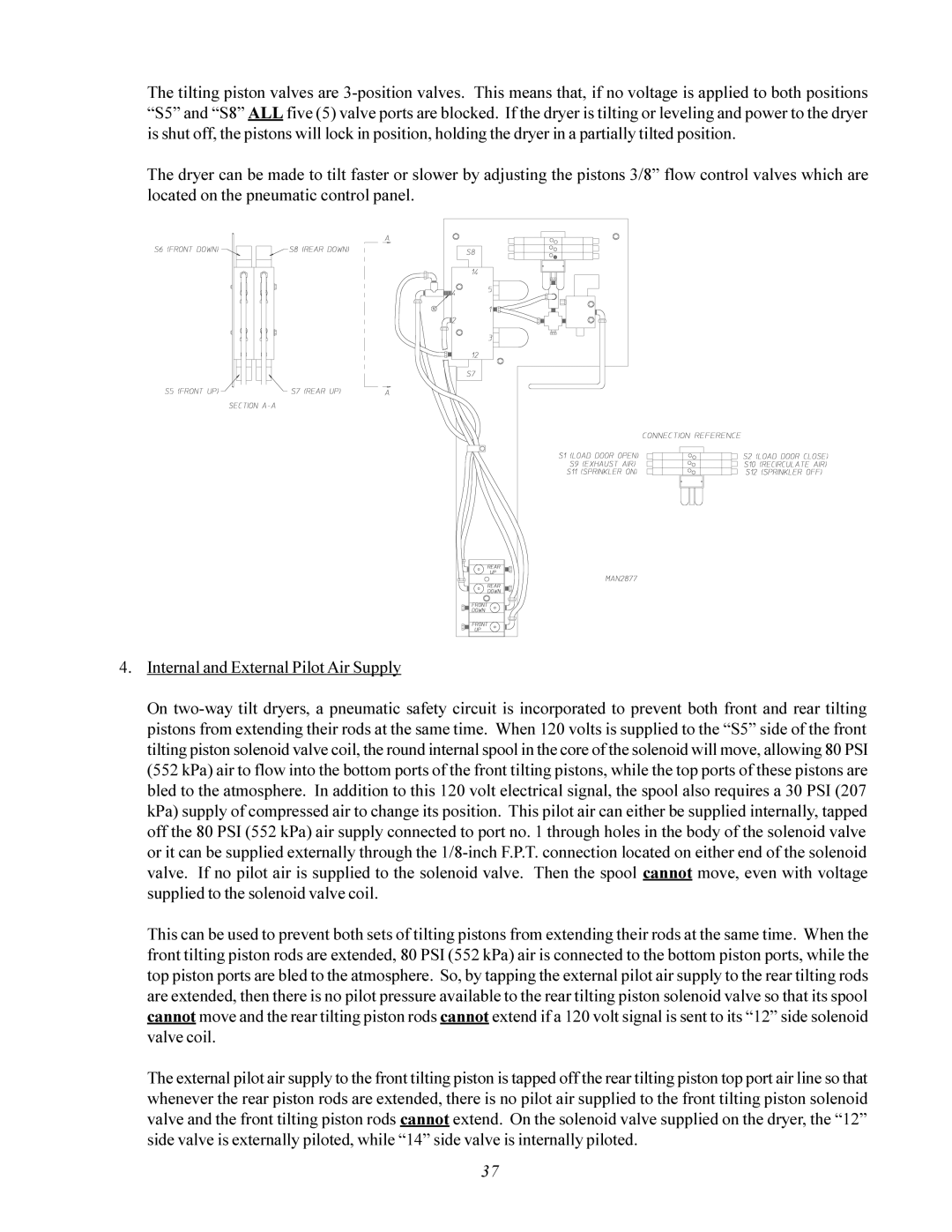

3.Pneumatic Control Panel

The pneumatic control panel of a

Each valve has five (5)

To tilt the dryer back, a 120 volt signal is applied to the front pistons solenoid connector #S5, and no voltage is applied to the solenoid connector #S8. The internal spool in the valve will move and 80 PSI (552 kPa) of air will enter the bottom port of the front tilting pistons, extending the front tilting piston rods and tilting the dryer back for loading. The top piston ports are bled to the atmosphere. To level the dryer after loading, the voltage signals are reversed. No voltage is applied to the “S5” solenoid, and 120 volts are applied to the “S8” solenoid. The valve spool will now move so that 80 PSI (552 kPa) of air is applied at the top piston ports, while the bottom piston ports are bled to the atmosphere. The piston rods will now retract, leveling the dryer. On

36