start-up

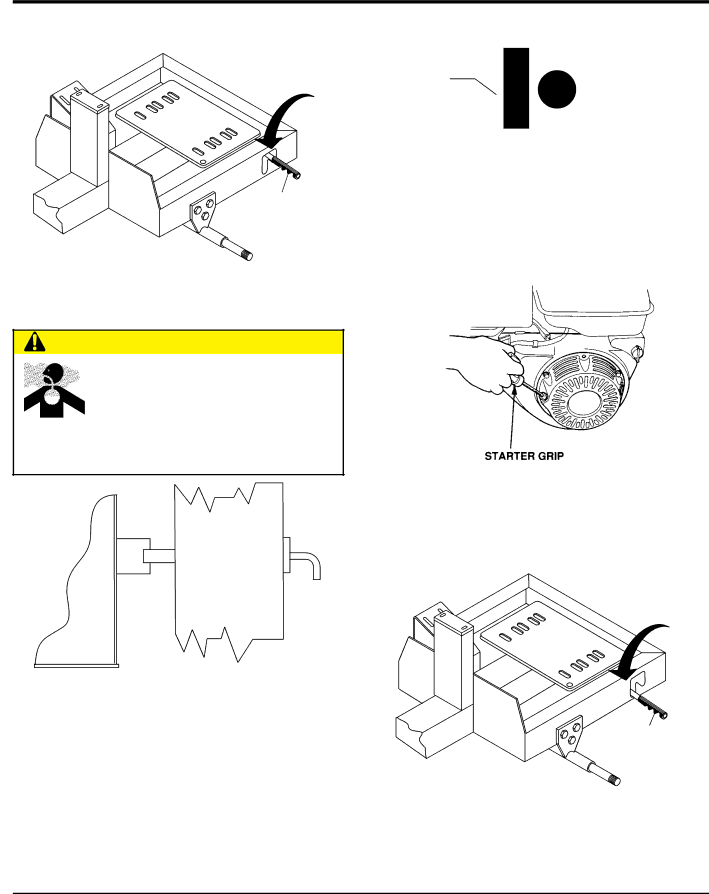

6.Place the belt slip lever (Figure 19) in the START/STOP (disengaged) position.

START/STOP

STOP

DRUM LATCH ![]() PIN

PIN

POSITION

BELT SLIP

LEVER

Figure 19. Belt Slip Lever

(Start/Stop Position)

![]() CAUTION

CAUTION

Make certain the drum lock pin (Figure 20

and Figure 21) is placed to the RIGHT (when

![]()

![]()

![]()

![]() viewing the mixer from the towpole end) of the drum stop block which is welded to the front side of the drum. Also make sure lock pin is fully

viewing the mixer from the towpole end) of the drum stop block which is welded to the front side of the drum. Also make sure lock pin is fully

engaged (locked).This will prevent the drum from tipping.

LOCK

PIN

FRONT

POST

DRUM

Figure 20. Drum Lock Pin (Side-View)

BLOCK

TOW OR LOCKED

POSITION

Figure 21. Drum Lock Pin (Right Position)

7.Pull the starter grip (Figure 22) lightly until you feel resistance, then pull briskly. Return the starter grip gently.

Figure 22. Starter Grip

8.Place the belt slip lever (Figure 23) in the mix position. This will tilt the engine placing tension on the

MIX

POSITION

BELT SLIP

LEVER