|

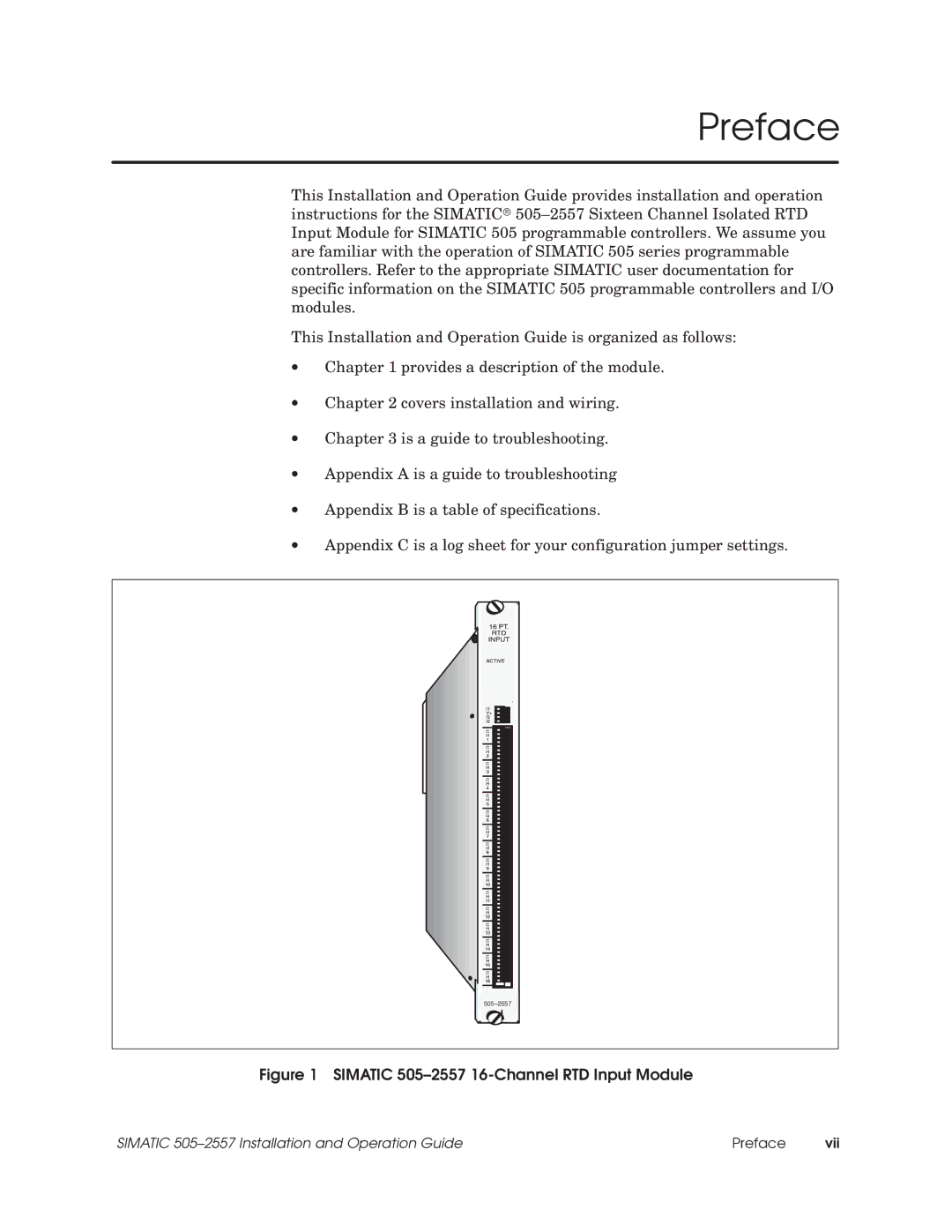

| Chapter 2 | |

|

| Installation | |

|

|

|

|

2.1 | Installing and Configuring the Module | . . . . . . . . . . . . . . . . . . . | |

| Planning the Installation | . . . . . . . . . . . . . . . . . . . | |

| Calculating the I/O Base Power Budget | . . . . . . . . . . . . . . . . . . . | |

| Unpacking the Module | . . . . . . . . . . . . . . . . . . . | |

| Configuring the Module | . . . . . . . . . . . . . . . . . . . | |

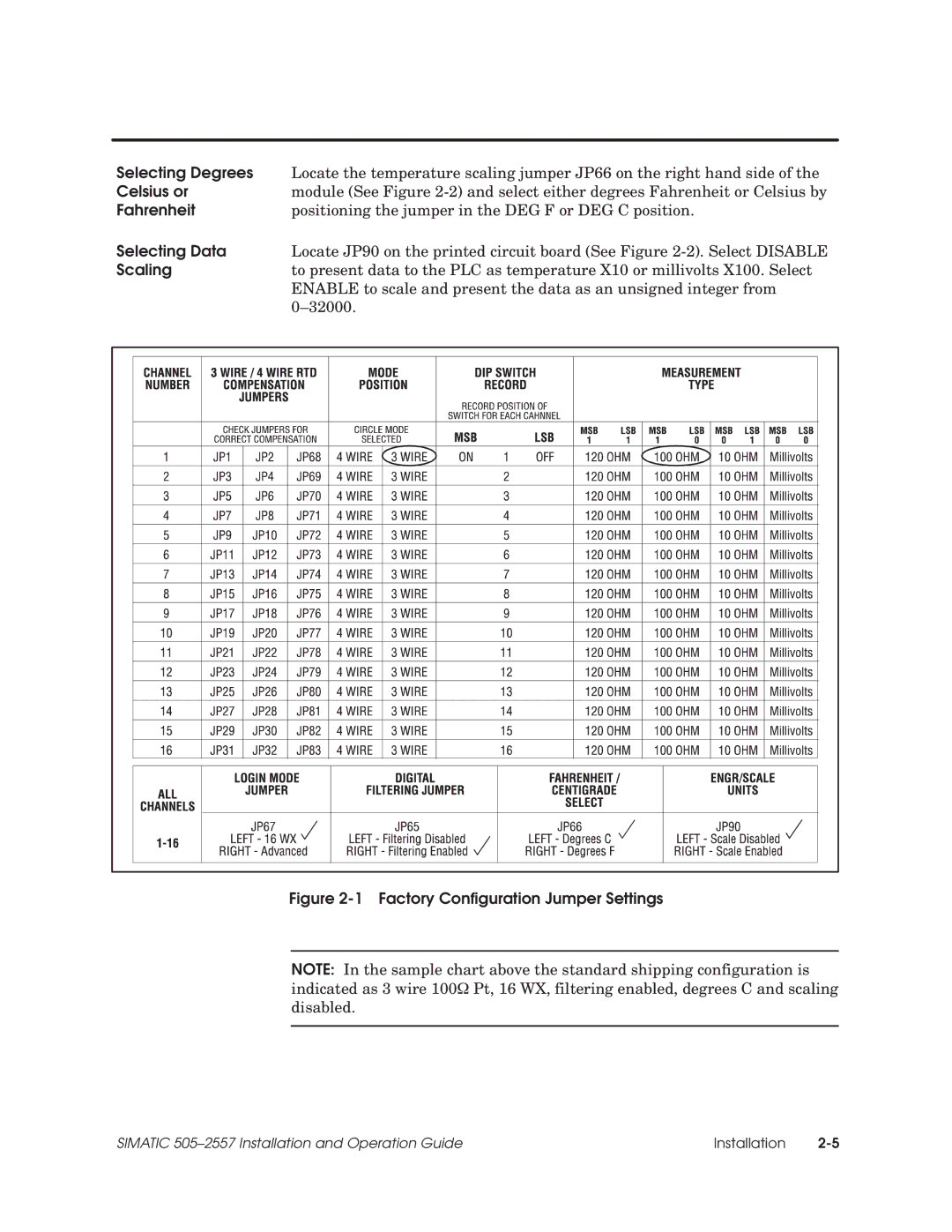

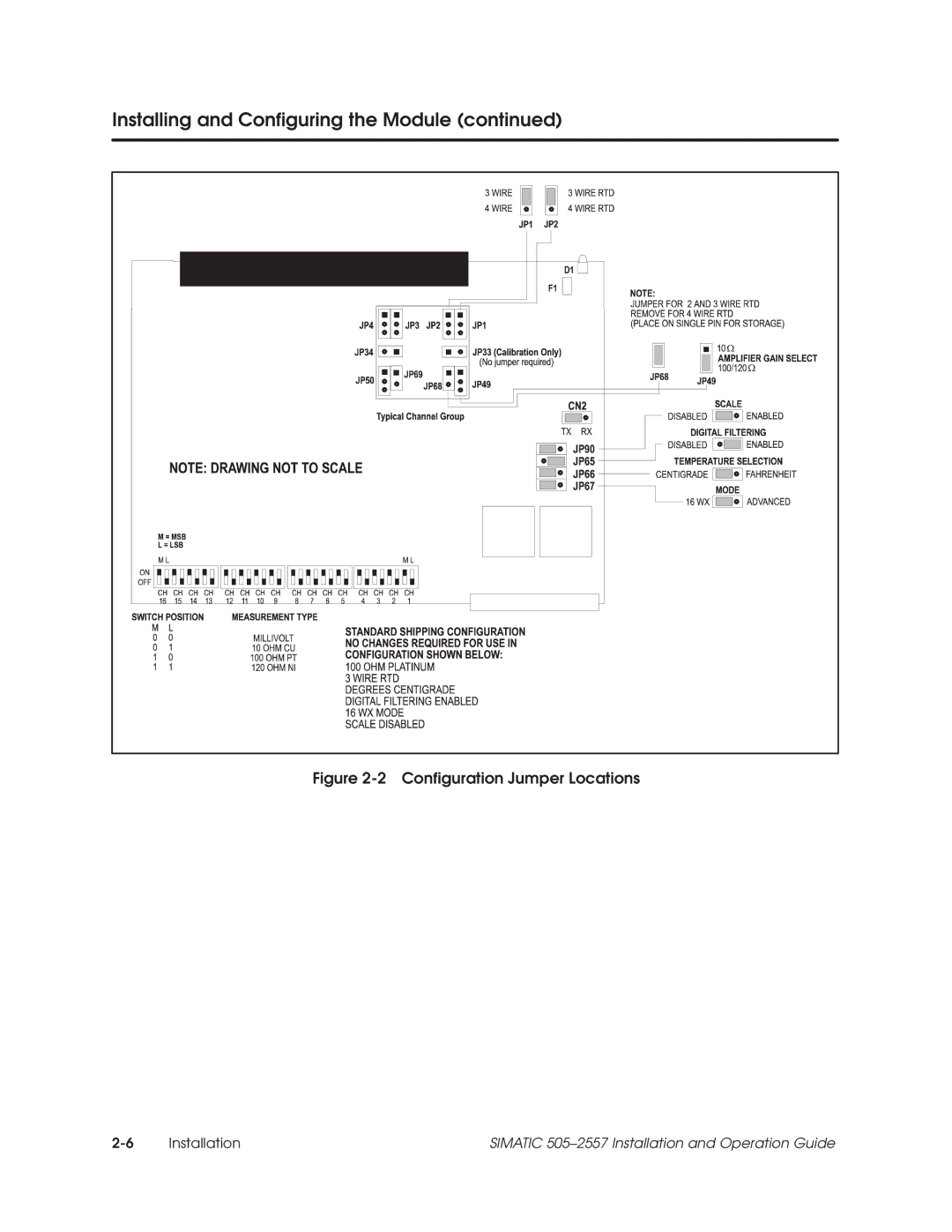

| Selecting Temperature or Millivolt Input | . . . . . . . . . . . . . . . . . . . | |

| Selecting 2 and 3 Wire or 4 Wire Operation | . . . . . . . . . . . . . . . . . . . | |

| Selecting 10 Ohm RTD Inputs | . . . . . . . . . . . . . . . . . . . | |

| Selecting PLC Login Mode | . . . . . . . . . . . . . . . . . . . | |

| Selecting Digital Filtering | . . . . . . . . . . . . . . . . . . . | |

| Selecting Degrees Celsius or Fahrenheit | . . . . . . . . . . . . . . . . . . . | |

| Selecting Data Scaling | . . . . . . . . . . . . . . . . . . . | |

| Inserting the Module Into the I/O Base | . . . . . . . . . . . . . . . . . . . | |

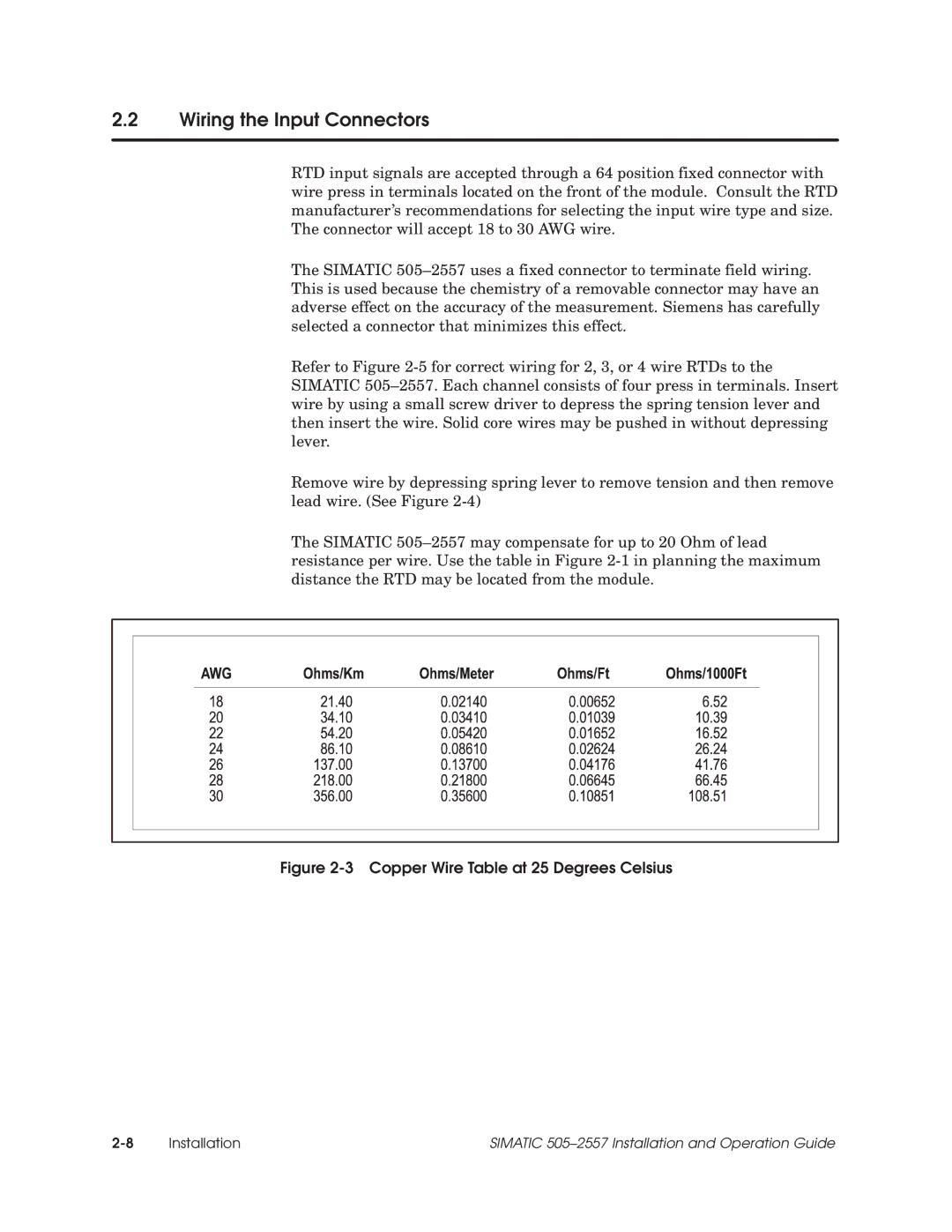

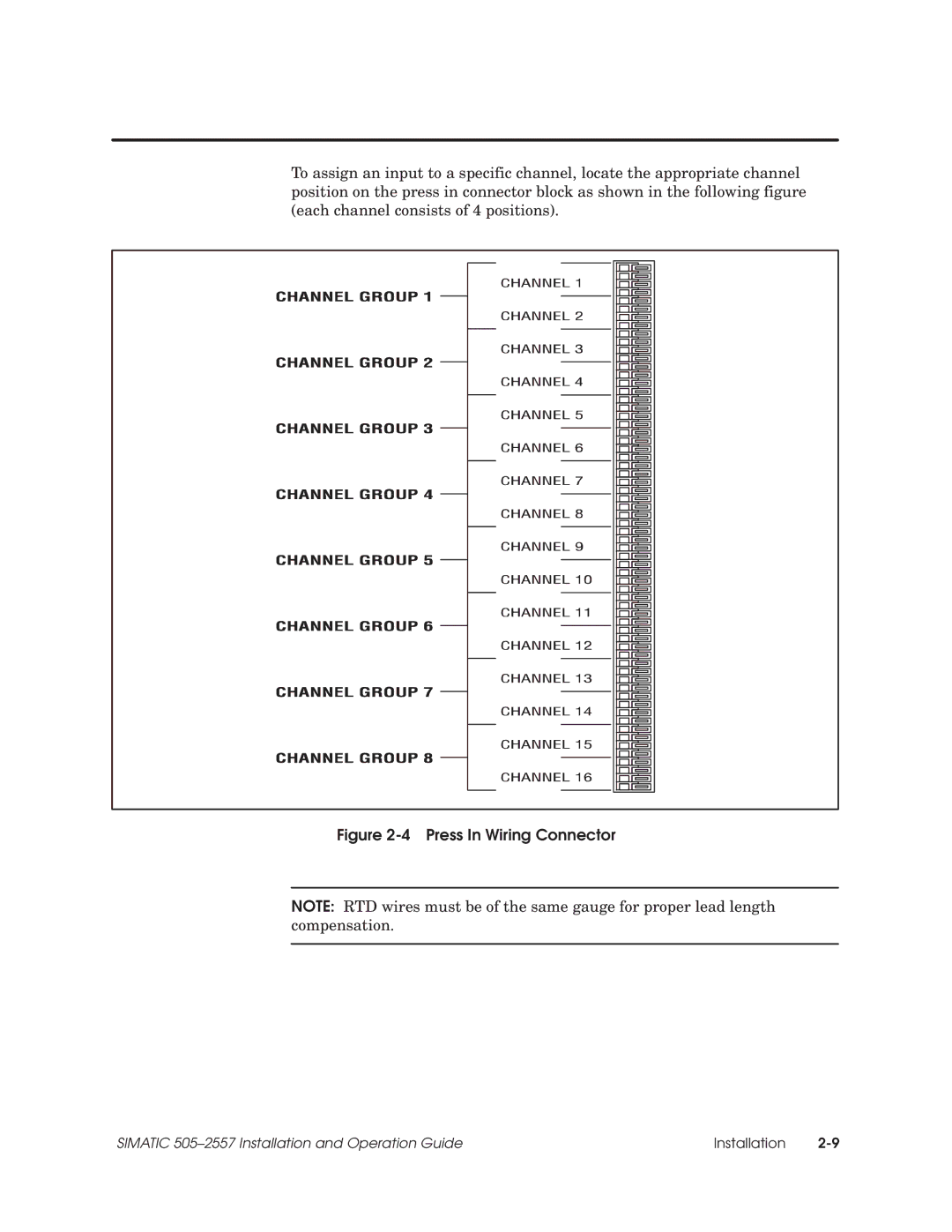

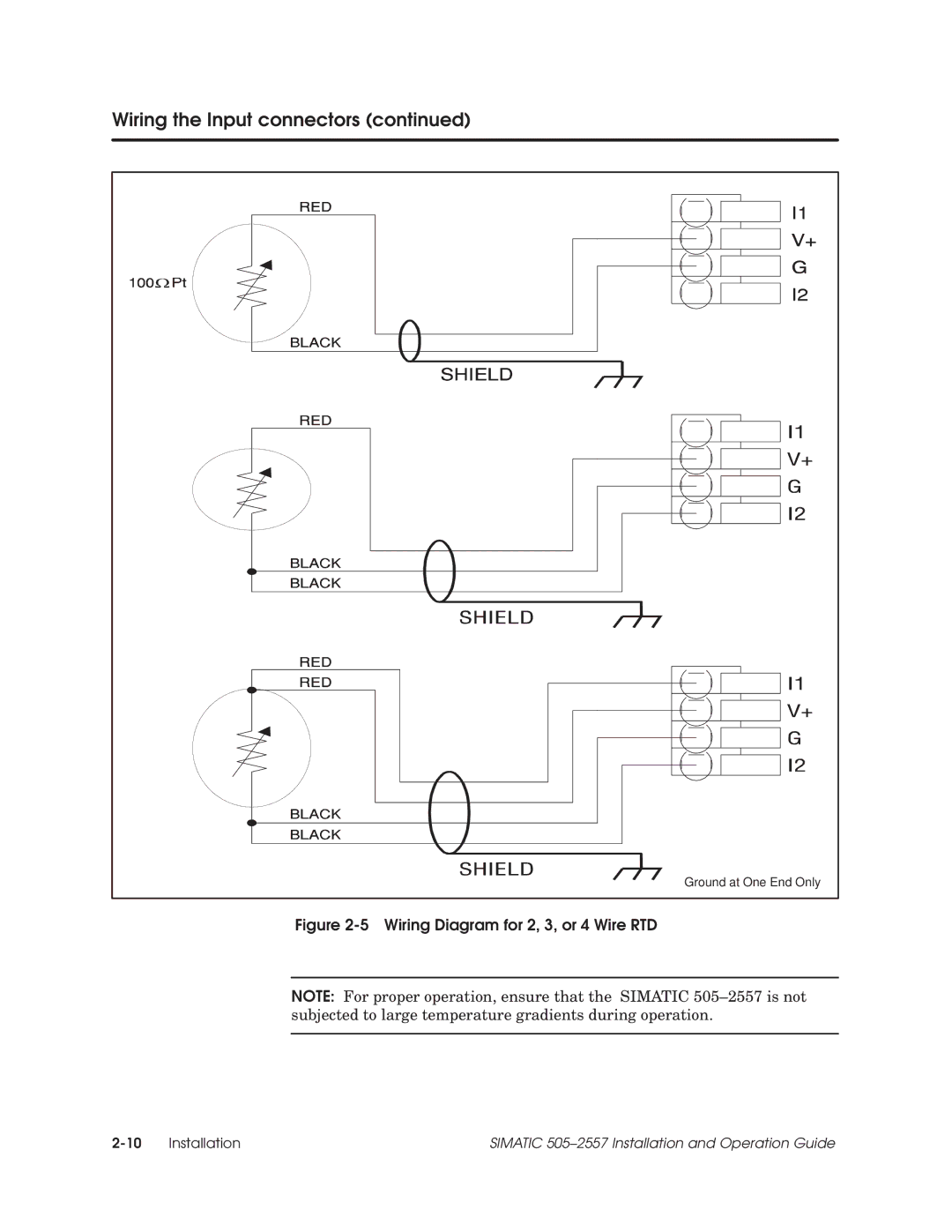

2.2 | Wiring the Input Connectors | . . . . . . . . . . . . . . . . . . . | |

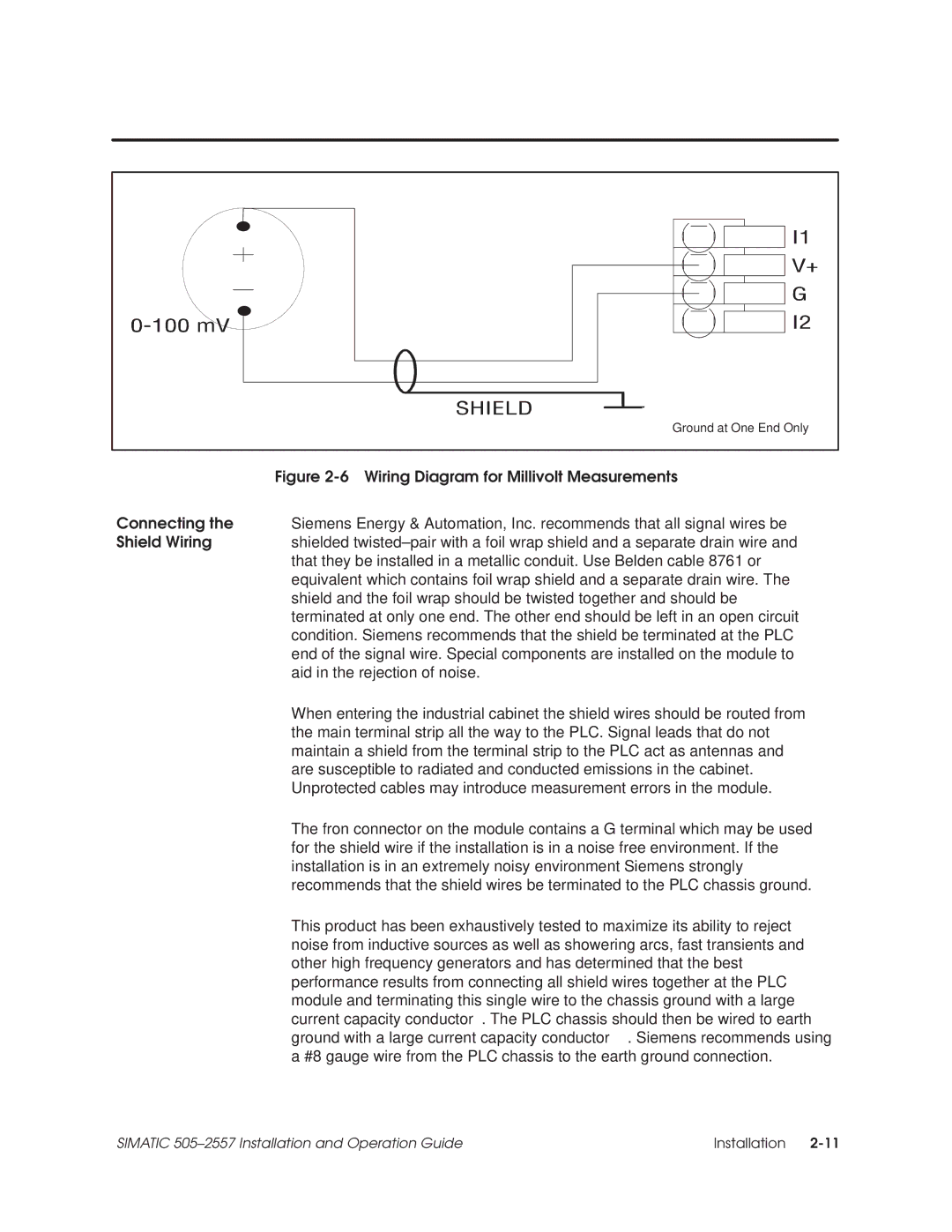

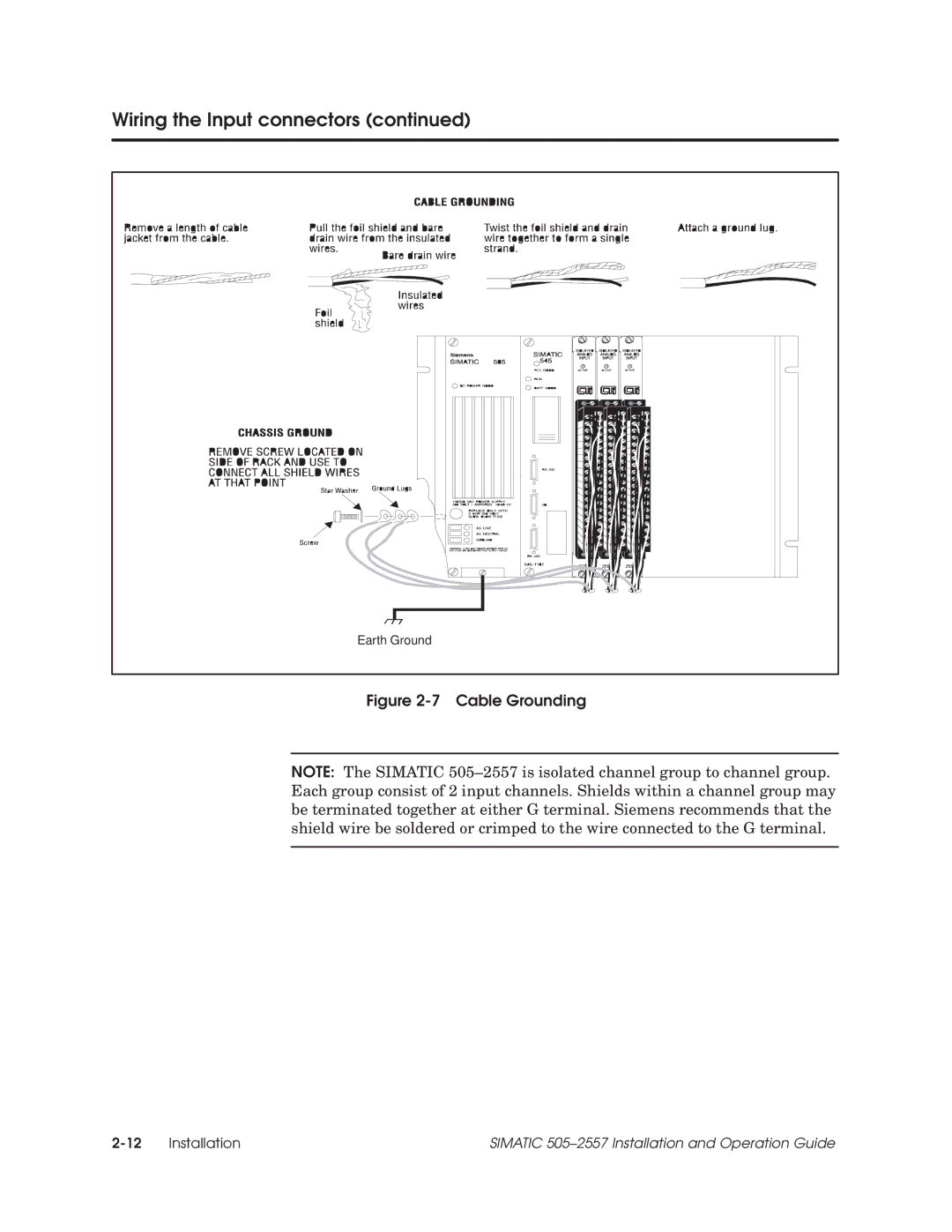

| Connecting the Shield Wiring | . . . . . . . . . . . . . . . . . . . | |

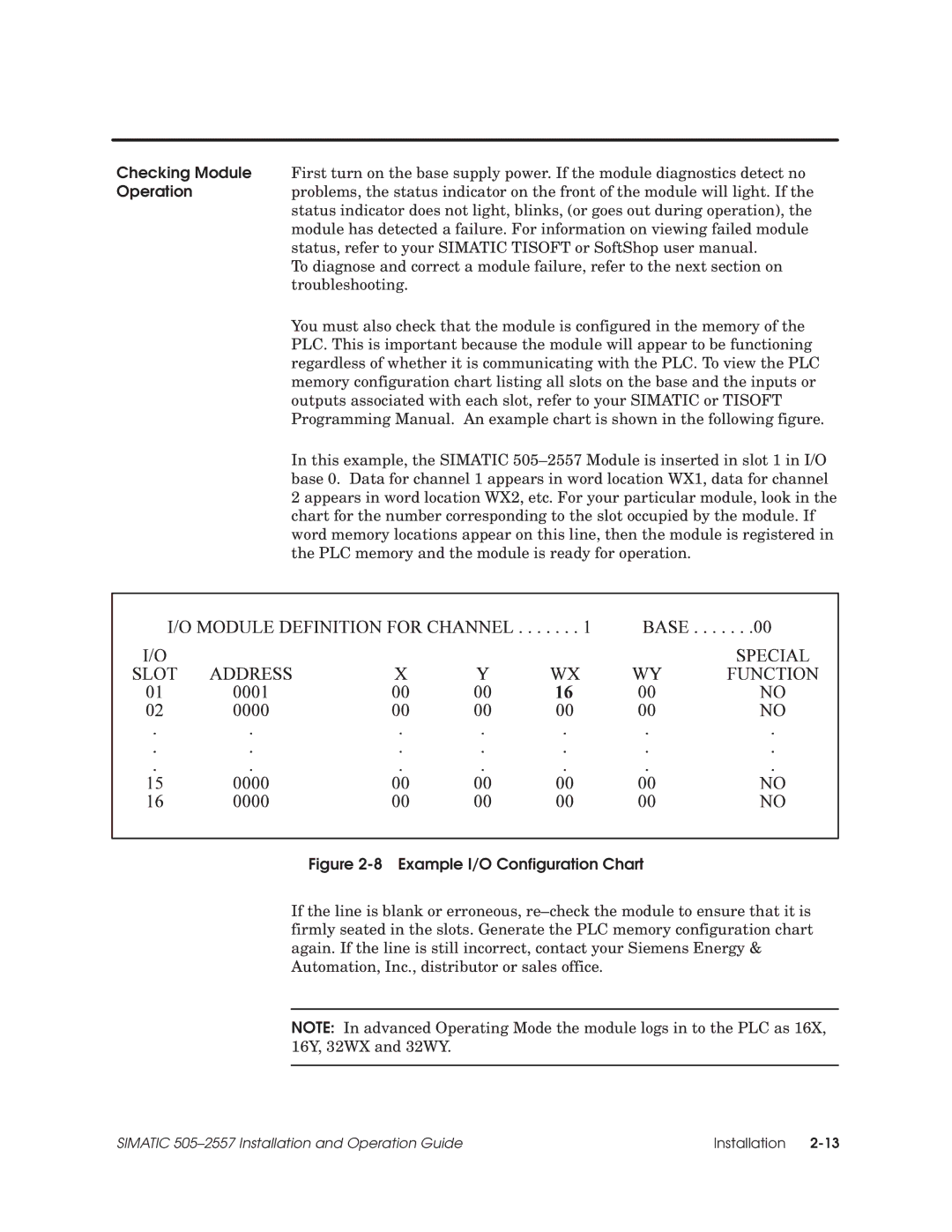

| Checking Module Operation | . . . . . . . . . . . . . . . . . . . | |

SIMATIC 505±2557 Installation and Operation Guide | Installation |