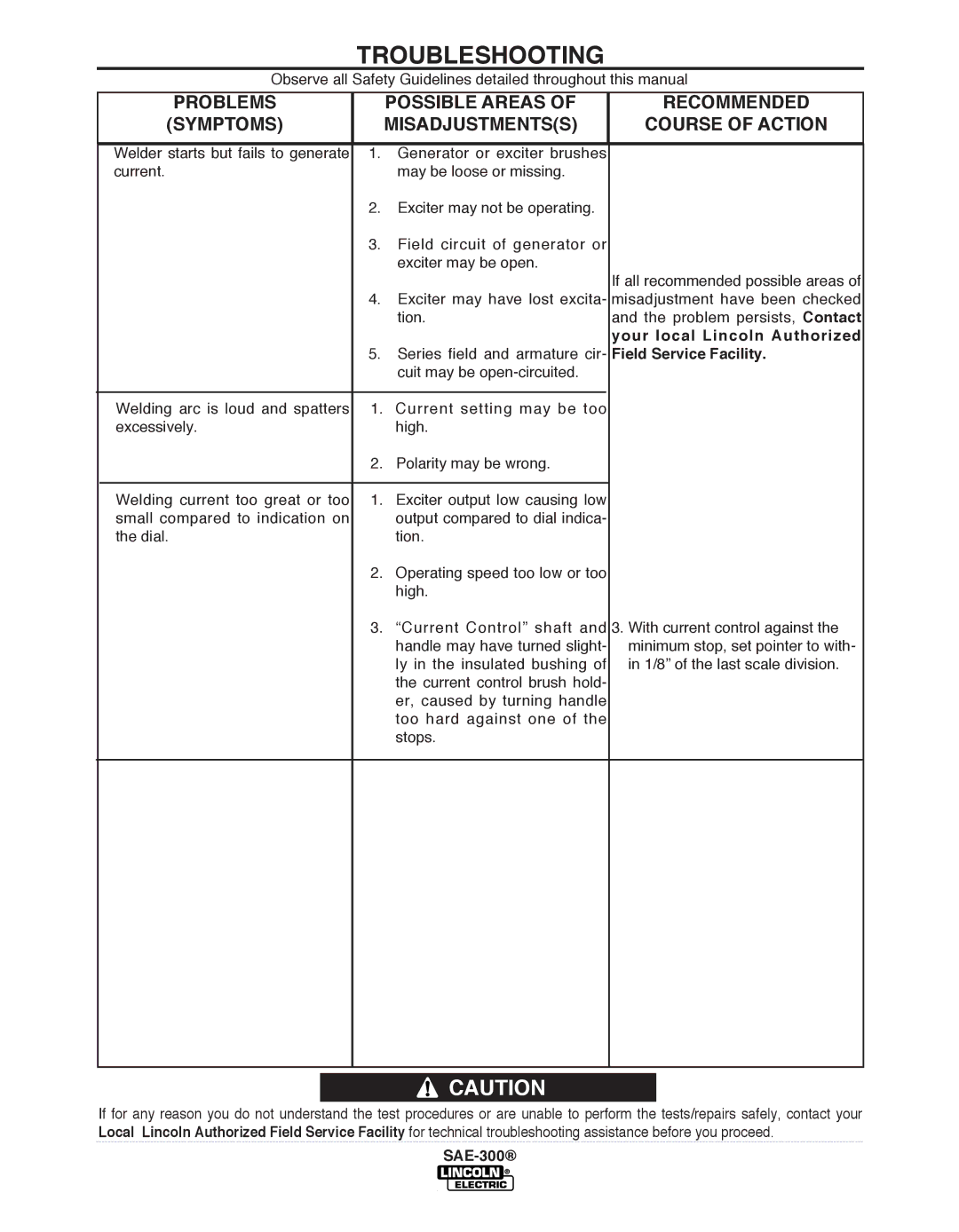

TROubLEShOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

|

|

|

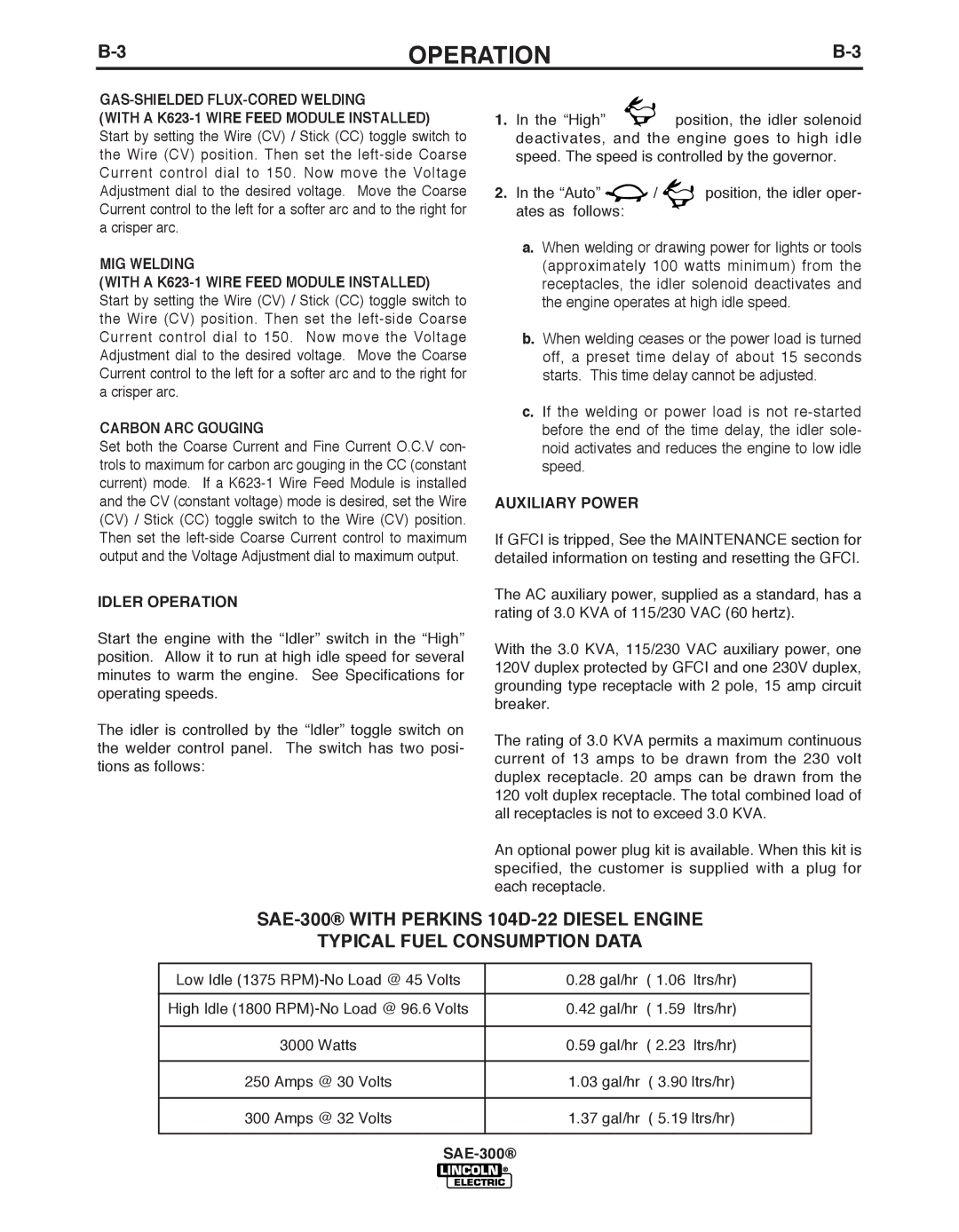

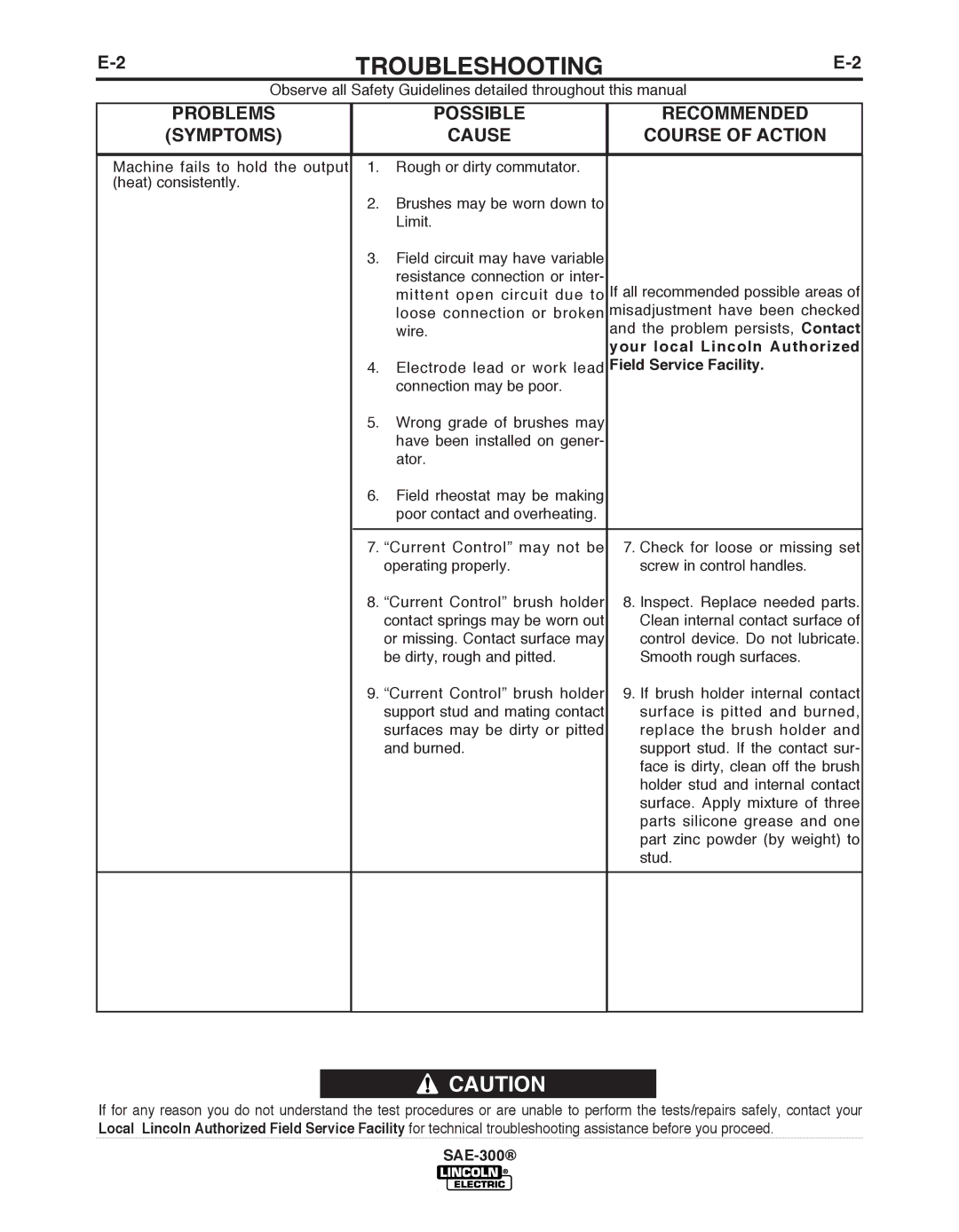

PRObLEMS

(SYMPTOMS)

POSSIbLE

CAuSE

RECOMMENDED

COuRSE OF ACTION

Machine fails to hold the output (heat) consistently.

1.Rough or dirty commutator.

2.Brushes may be worn down to Limit.

3.Field circuit may have variable

resistance connection or inter-

mittent open circuit due to If all recommended possible areas of

loose connection or broken misadjustment have been checked

wire.and the problem persists, Contact your local Lincoln Authorized

4.Electrode lead or work lead Field Service Facility. connection may be poor.

5.Wrong grade of brushes may have been installed on gener- ator.

6.Field rheostat may be making poor contact and overheating.

7. “Current Control” may not be | 7. Check for loose or missing set |

operating properly. | screw in control handles. |

8. “Current Control” brush holder | 8. Inspect. Replace needed parts. |

contact springs may be worn out | Clean internal contact surface of |

or missing. Contact surface may | control device. Do not lubricate. |

be dirty, rough and pitted. | Smooth rough surfaces. |

9. “Current Control” brush holder | 9. If brush holder internal contact |

support stud and mating contact | surface is pitted and burned, |

surfaces may be dirty or pitted | replace the brush holder and |

and burned. | support stud. If the contact sur- |

| face is dirty, clean off the brush |

| holder stud and internal contact |

| surface. Apply mixture of three |

| parts silicone grease and one |

| part zinc powder (by weight) to |

| stud. |

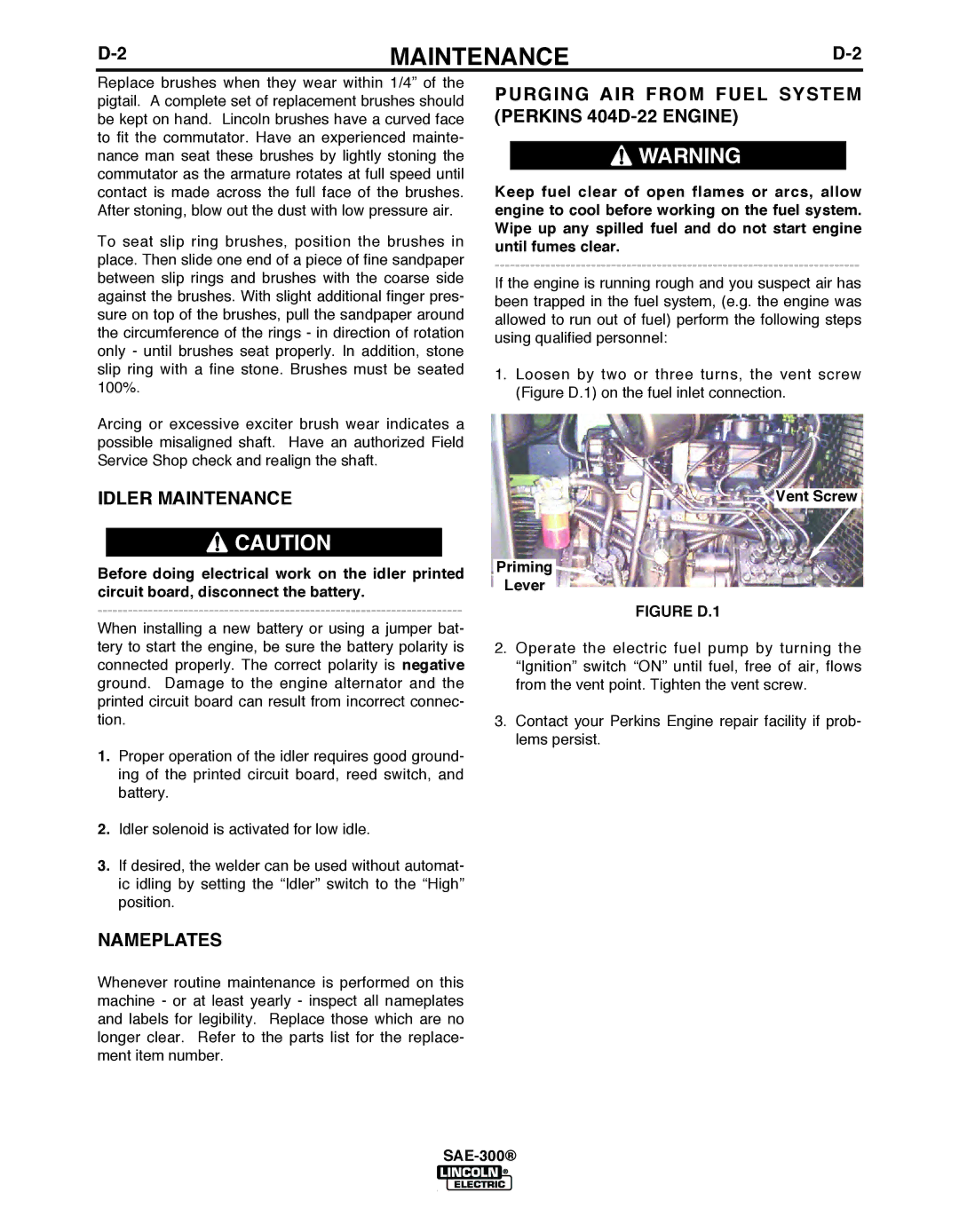

![]() CAuTION

CAuTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.