to Section TOC

to Master TOC

ACCESSORIES | ||

|

|

|

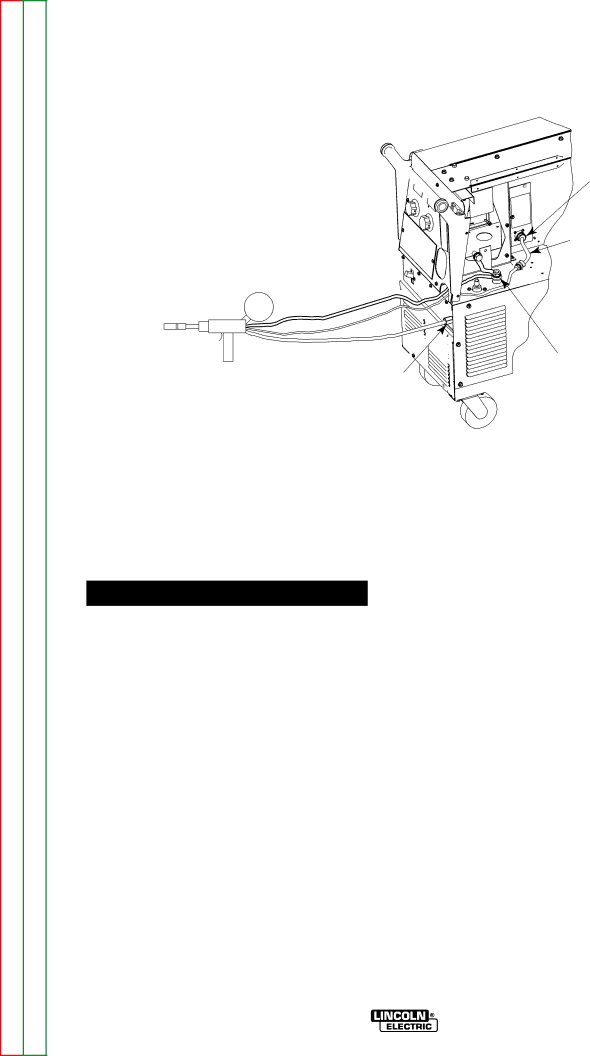

| FIGURE C.1 |

|

Return

to Section TOC

GAS LINE

AND 5/8 FITTING

CABLE ADAPTER

Note: This adapter is only for The Magnum SG Spool Gun.

+POSITIVE CABLE AND STUD

Return

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

MAKING A WELD WITH THE PRINCE XL SPOOL GUN

The POWER MIG control circuitry is designed to sense either the spool gun or (built in) wire feeder trigger circuitry. The spool gun can easily be plugged in and will be ready to use.

![]() CAUTION

CAUTION

Closing either gun trigger will cause the electrode of both guns to be electrically "HOT". Be sure unused gun is positioned so electrode or tip will not contact metal case or other metal common to work.

1.Pulling the trigger for the

a.Disables spool gun operation.

b.Closing feeder gun trigger starts feeder gun welding and makes both electrodes electrical- ly "HOT".

2.Pulling SPOOL GUN Trigger:

a.Disables

b.Closing spool gun trigger starts spool gun

3.Operation with POWER MIG 255C:

a.Turn the POWER MIG 255C input power ON.

b.Adjusting the voltage control will increase or decrease your welding voltage.

c.Adjusting the wire speed control on the spool gun will increase or decrease the spool gun wire feed speed.

d.To aid in

4.The following procedure settings for Aluminum 4043 can be used as initial settings for making test welds to determine final settings:

Wire Diameter | Wire Feed Speed | Arc voltage |

In. (mm) | Display | Setting |

.030” (.8mm) | 270 | 15V |

.035” (.9mm) | 250 | 16V |

3/64” (1.2mm) | 240 | 20V |

|

|

|

5.To return to normal POWER MIG 255C welding, release the spool gun trigger and reset feeder gun voltage procedure setting if necessary.

MAKING A WELD WITH THE MAGNUM SG SPOOL GUN

The POWER MIG control circuitry is designed to sense either the spool gun or (built in) wire feeder trigger circuitry. The spool gun can easily be plugged in and will be ready to use.

POWER MIG 255C