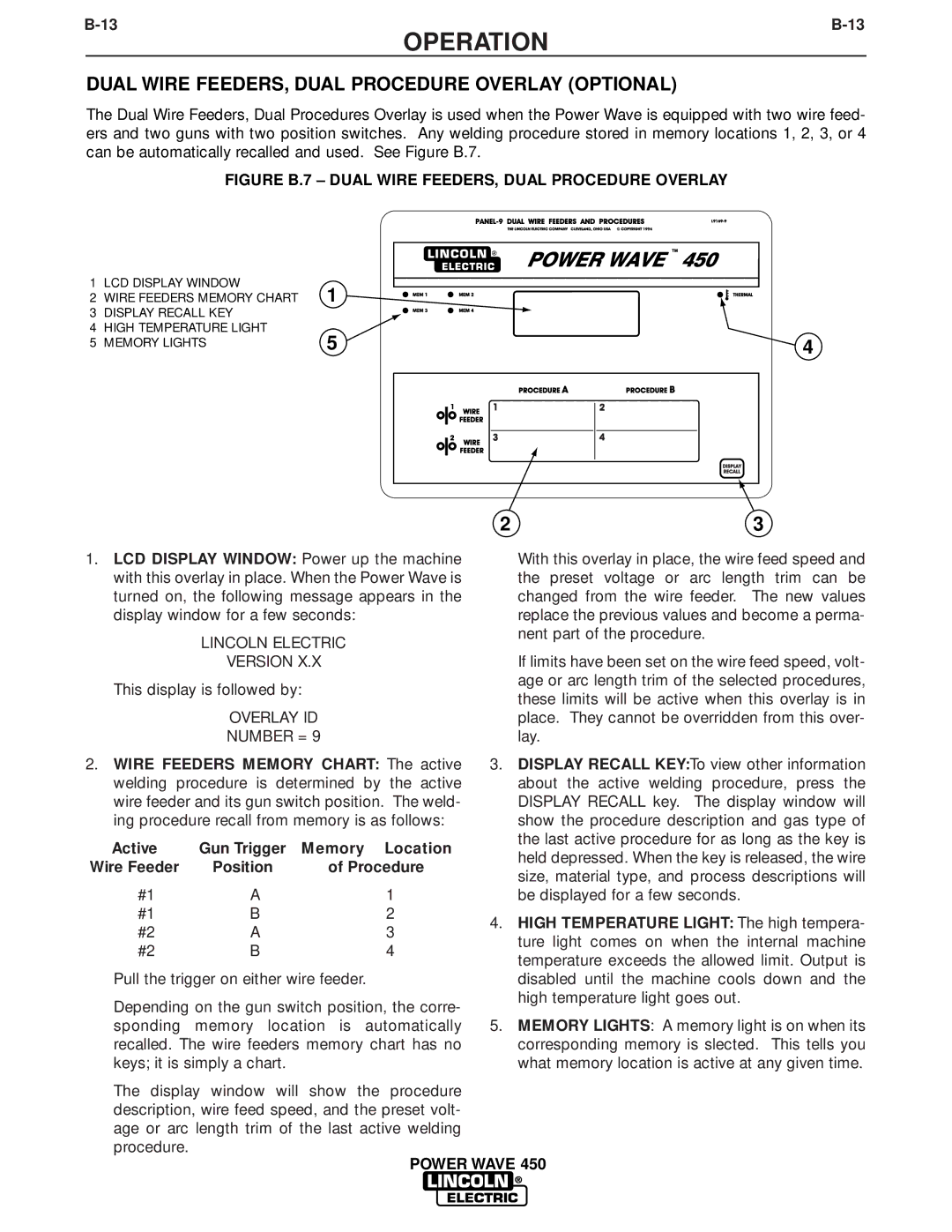

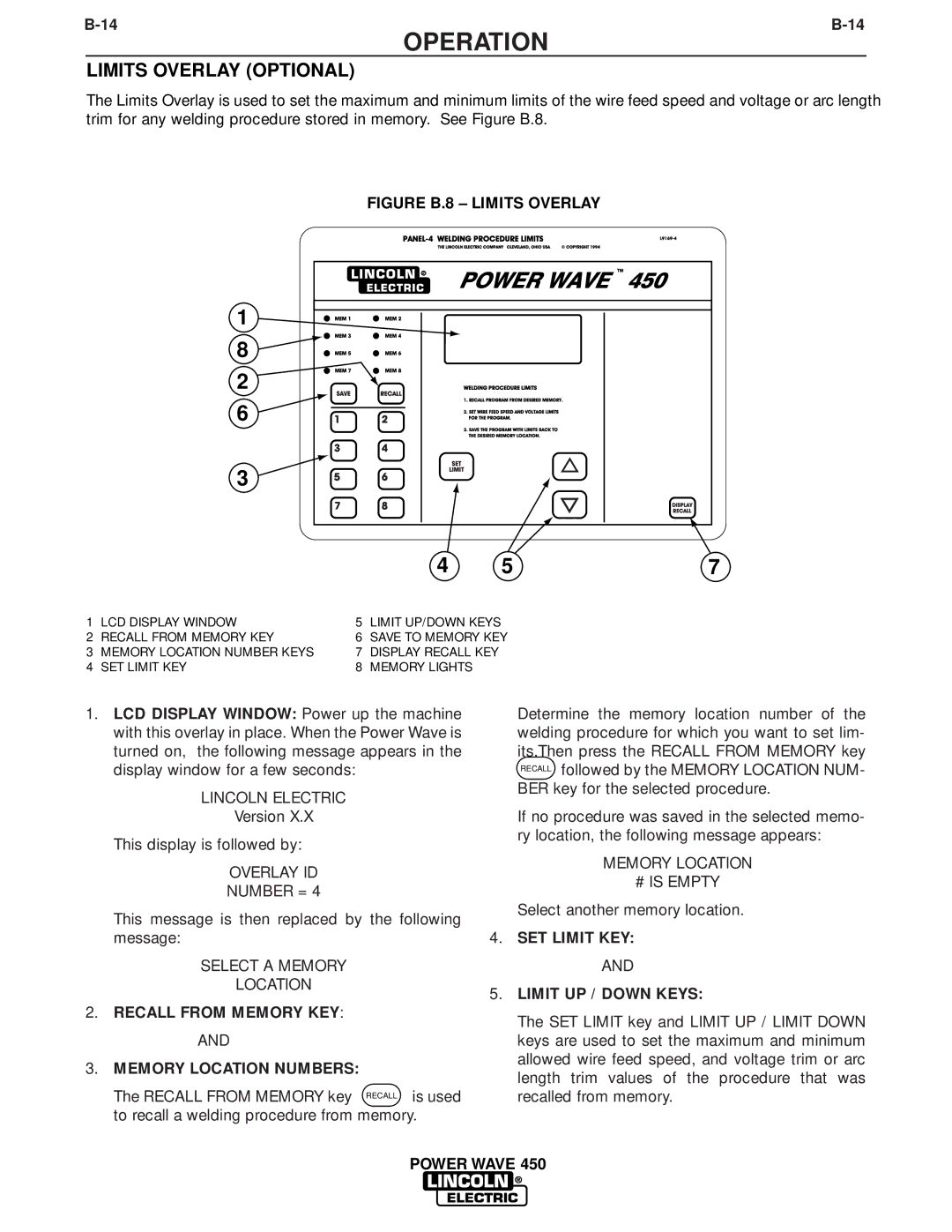

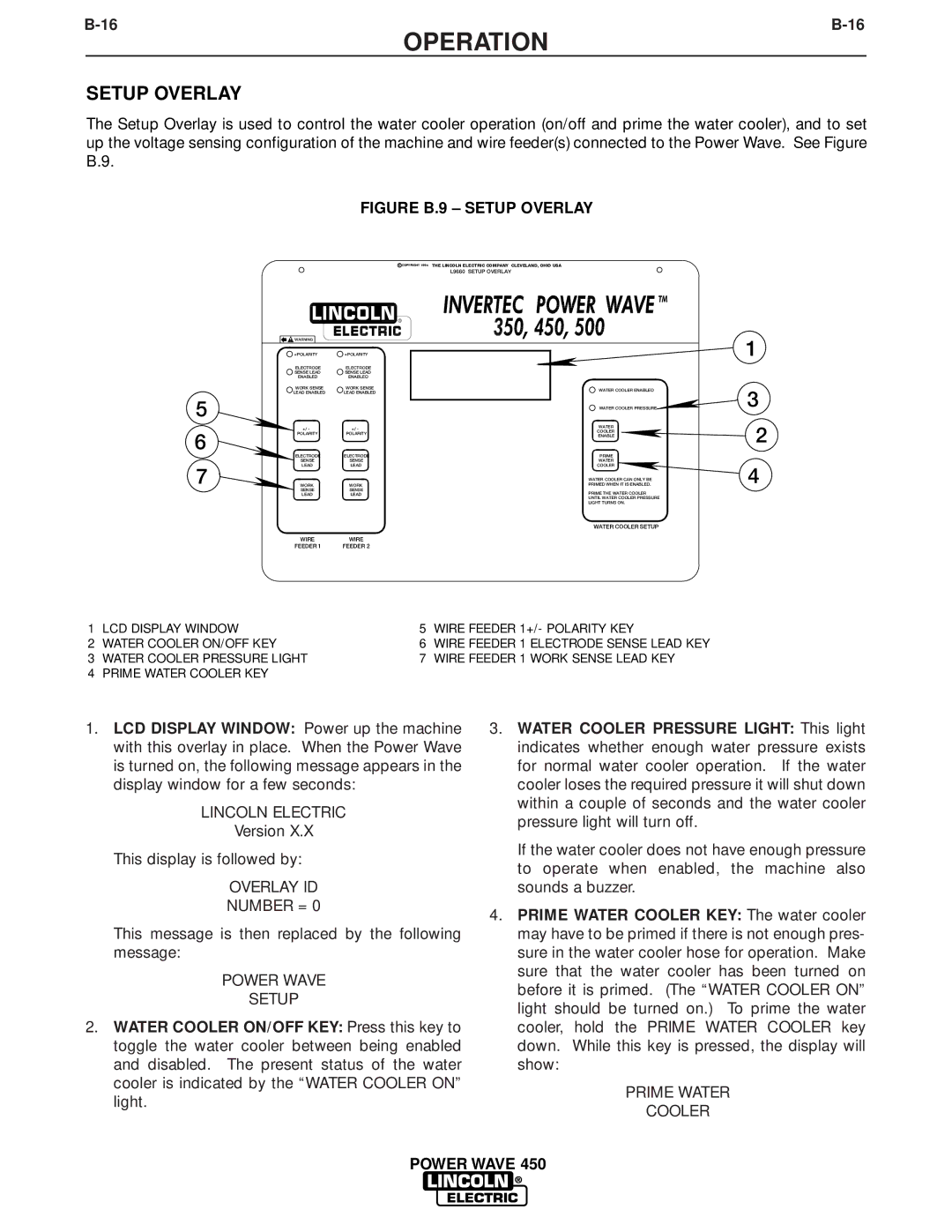

OPERATION

CONTROLS AND SETTINGS

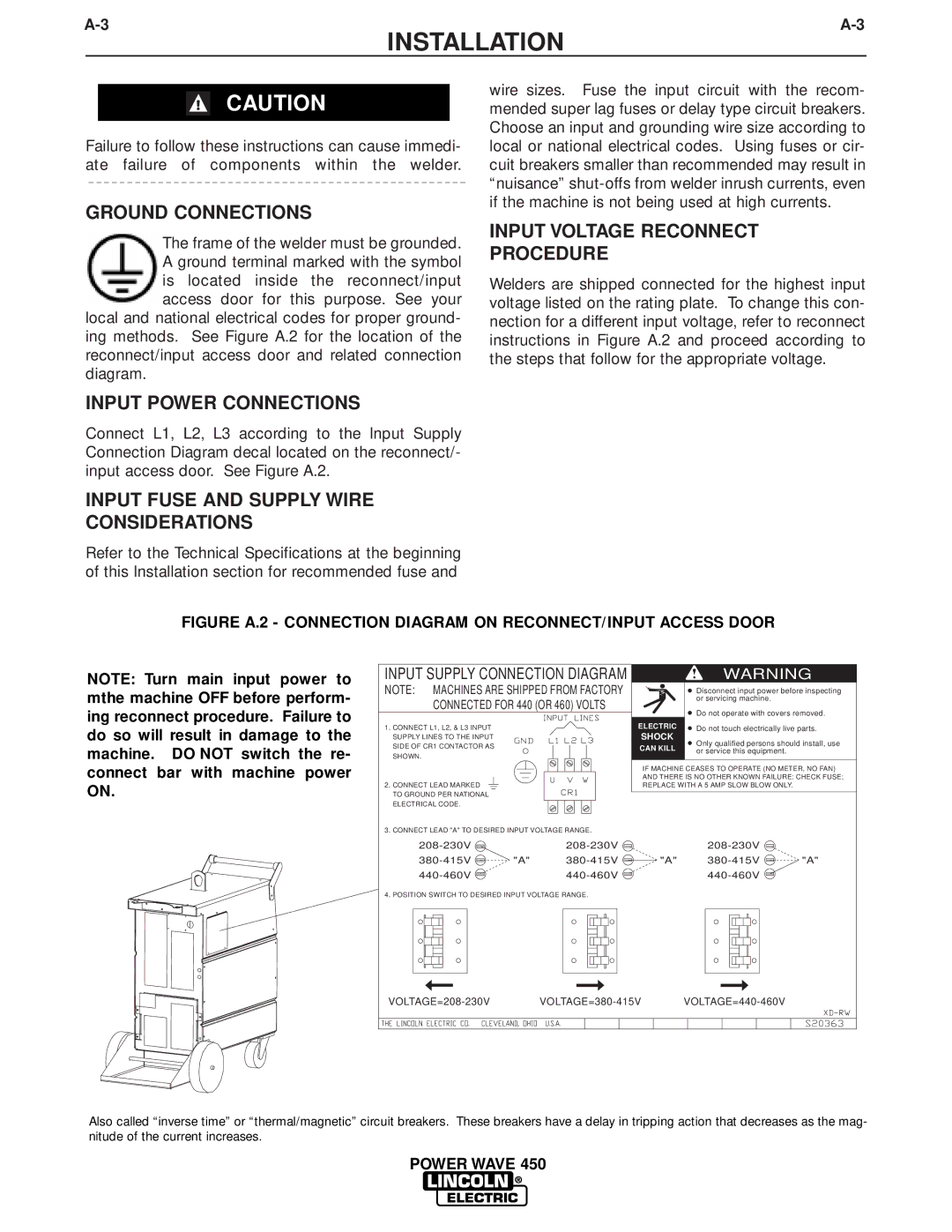

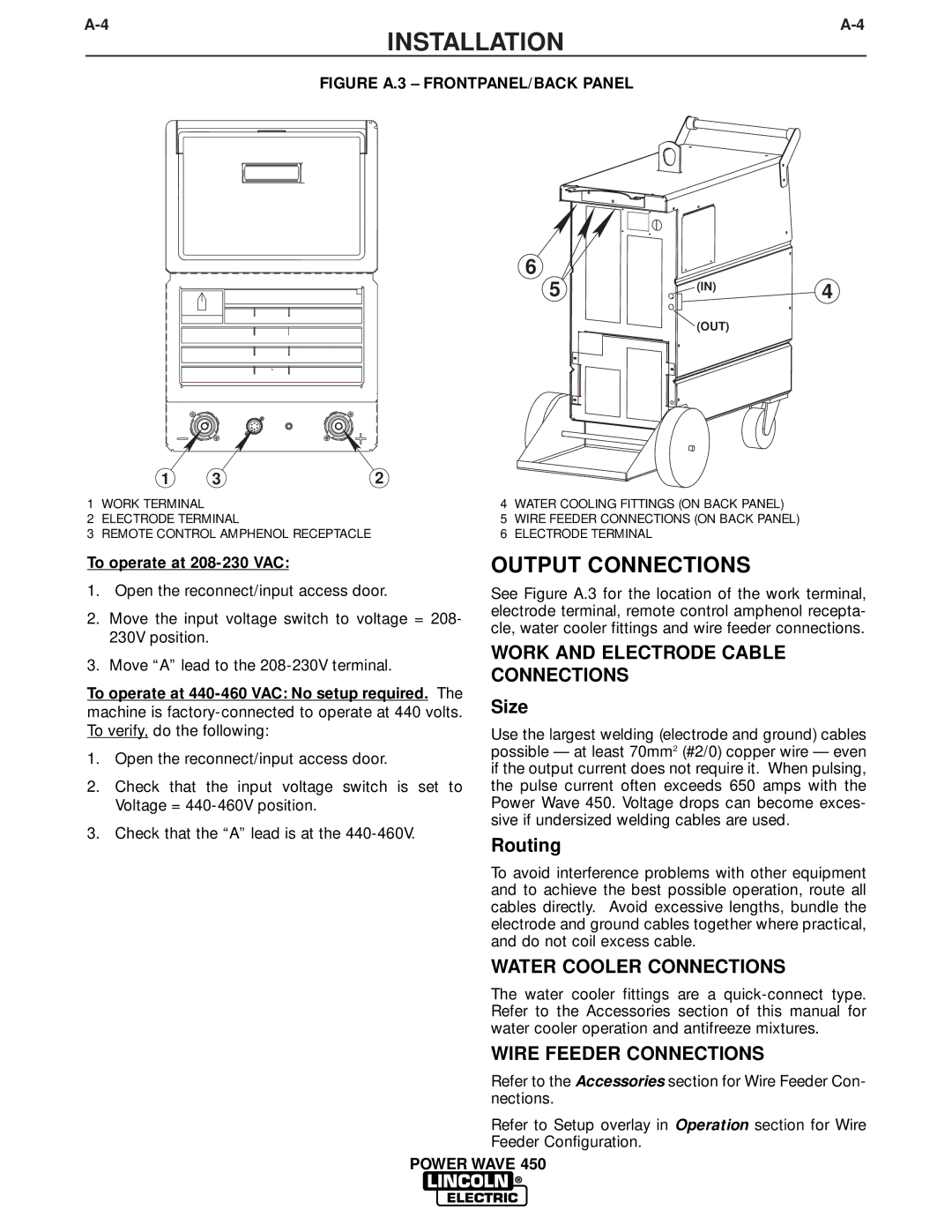

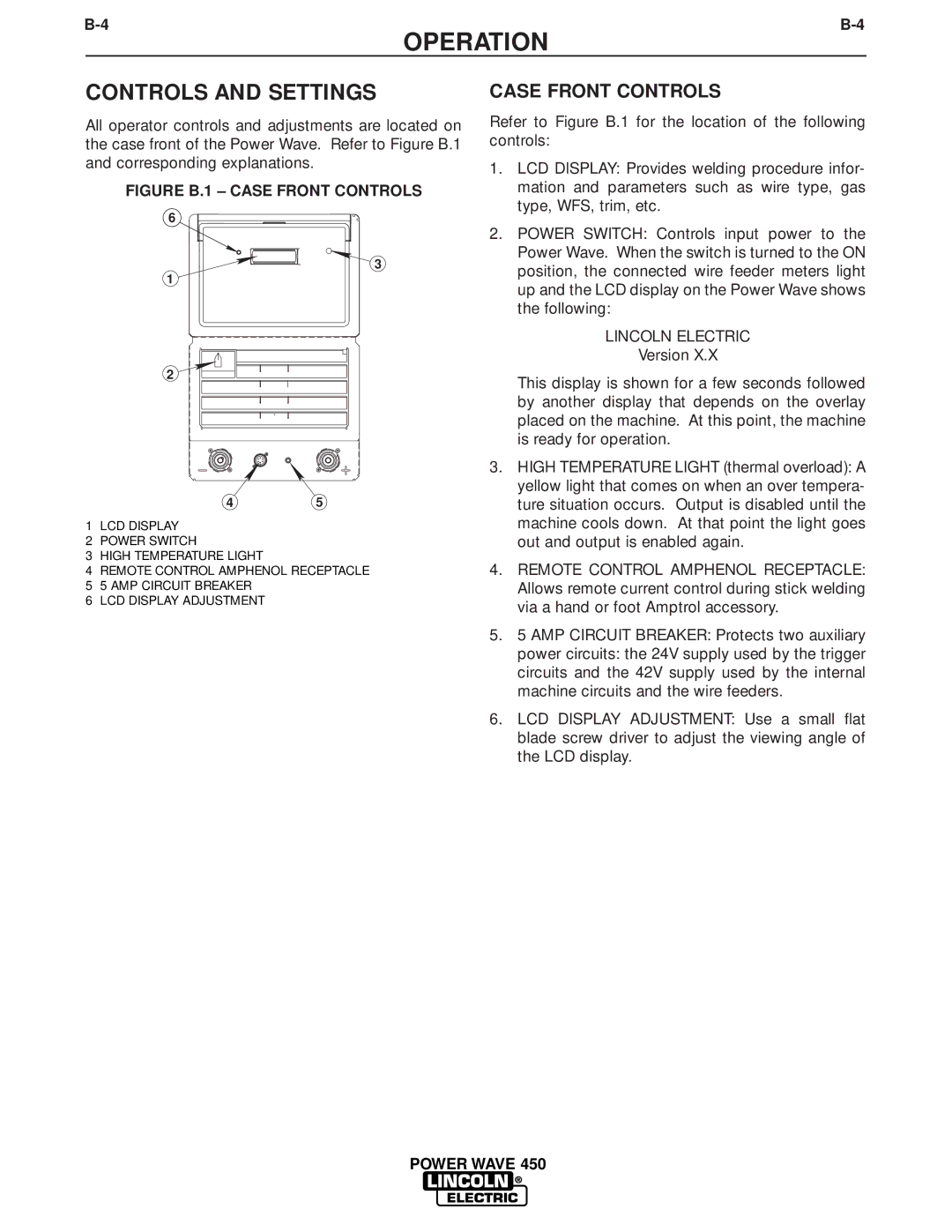

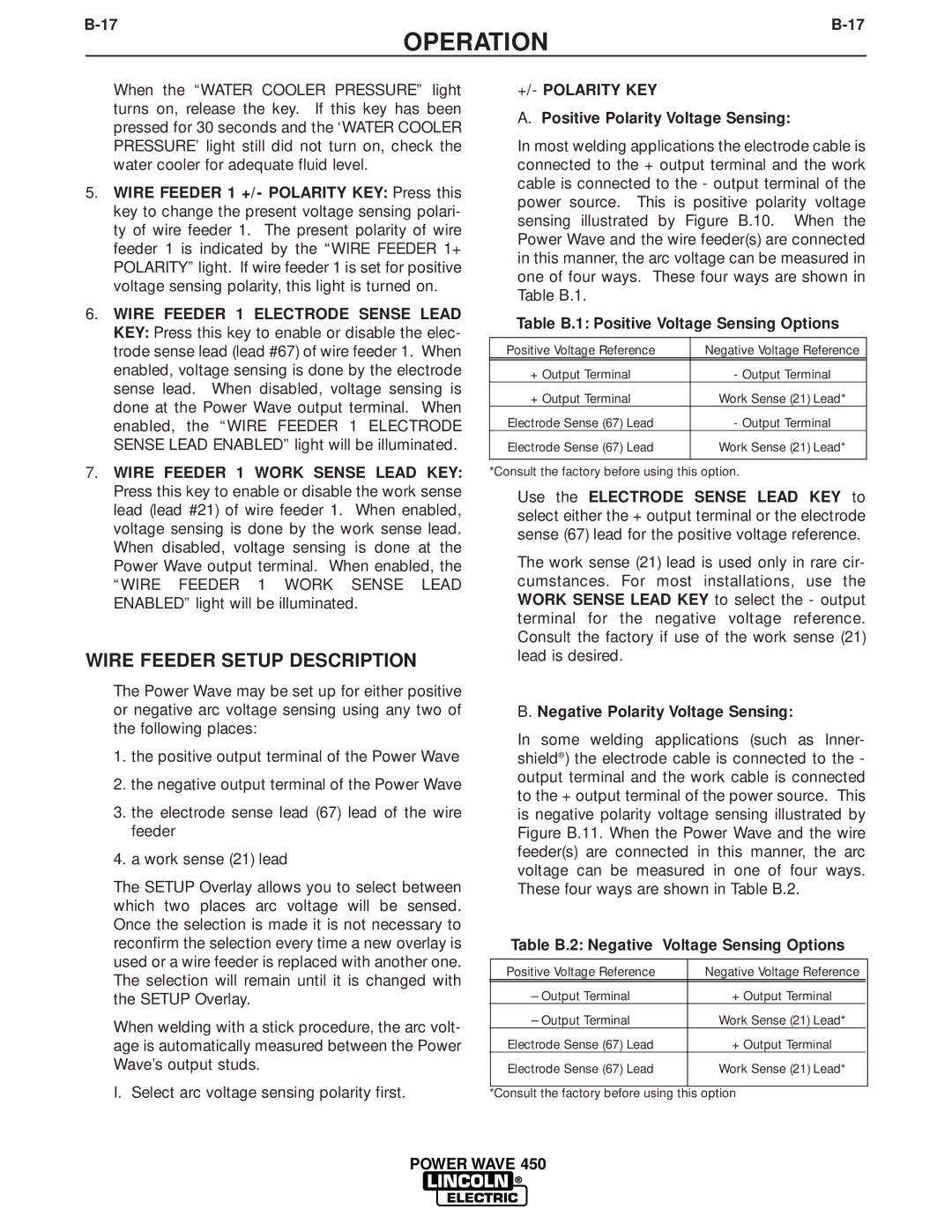

All operator controls and adjustments are located on the case front of the Power Wave. Refer to Figure B.1 and corresponding explanations.

FIGURE B.1 – CASE FRONT CONTROLS

6

3

1

2![]()

45

1LCD DISPLAY

2POWER SWITCH

3HIGH TEMPERATURE LIGHT

4REMOTE CONTROL AMPHENOL RECEPTACLE

55 AMP CIRCUIT BREAKER

6LCD DISPLAY ADJUSTMENT

CASE FRONT CONTROLS

Refer to Figure B.1 for the location of the following controls:

1.LCD DISPLAY: Provides welding procedure infor- mation and parameters such as wire type, gas type, WFS, trim, etc.

2.POWER SWITCH: Controls input power to the Power Wave. When the switch is turned to the ON position, the connected wire feeder meters light up and the LCD display on the Power Wave shows the following:

LINCOLN ELECTRIC

Version X.X

This display is shown for a few seconds followed by another display that depends on the overlay placed on the machine. At this point, the machine is ready for operation.

3.HIGH TEMPERATURE LIGHT (thermal overload): A yellow light that comes on when an over tempera- ture situation occurs. Output is disabled until the machine cools down. At that point the light goes out and output is enabled again.

4.REMOTE CONTROL AMPHENOL RECEPTACLE: Allows remote current control during stick welding via a hand or foot Amptrol accessory.

5.5 AMP CIRCUIT BREAKER: Protects two auxiliary

power circuits: the 24V supply used by the trigger circuits and the 42V supply used by the internal machine circuits and the wire feeders.

6.LCD DISPLAY ADJUSTMENT: Use a small flat blade screw driver to adjust the viewing angle of the LCD display.

POWER WAVE 450