TROUBLESHOOTING |

| ||||

|

|

|

|

| |

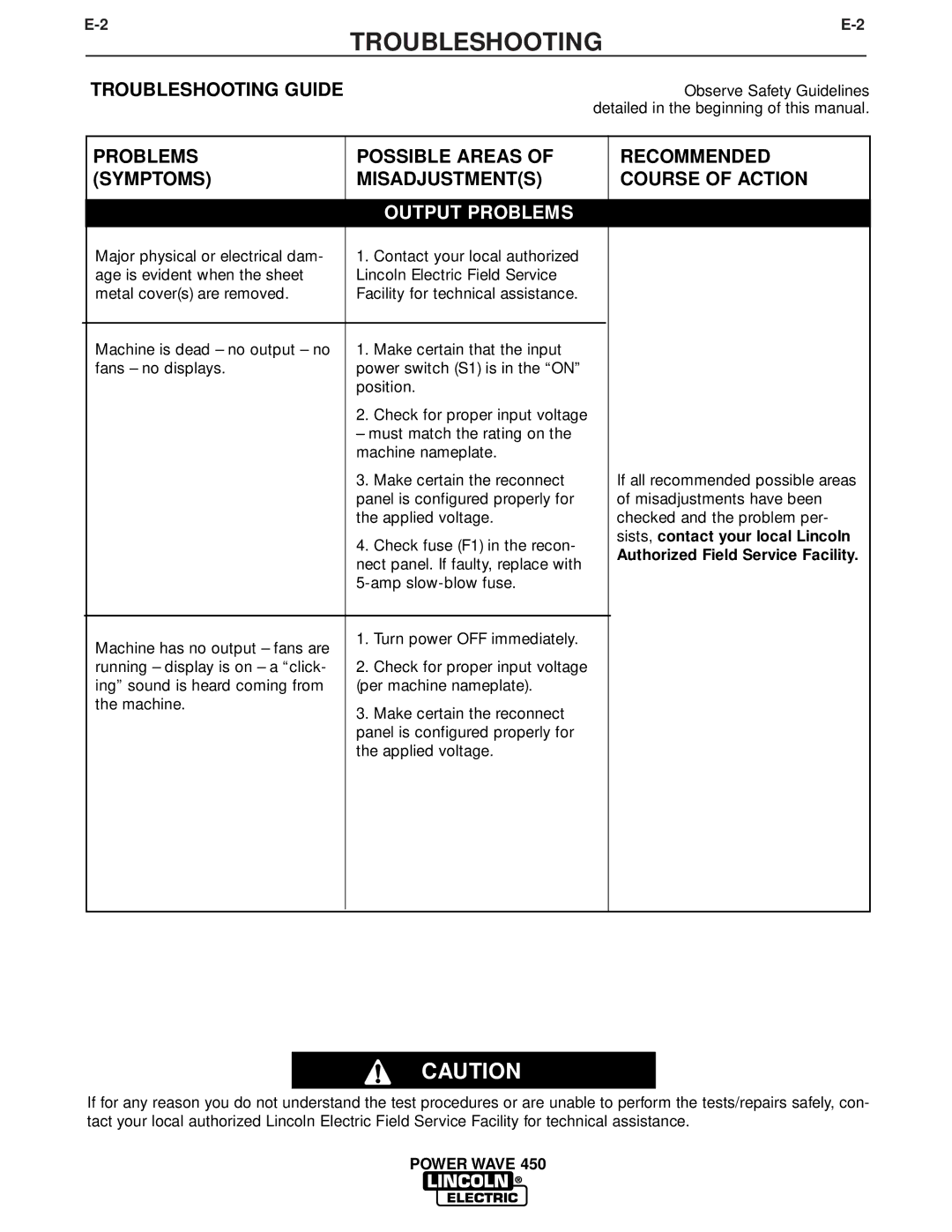

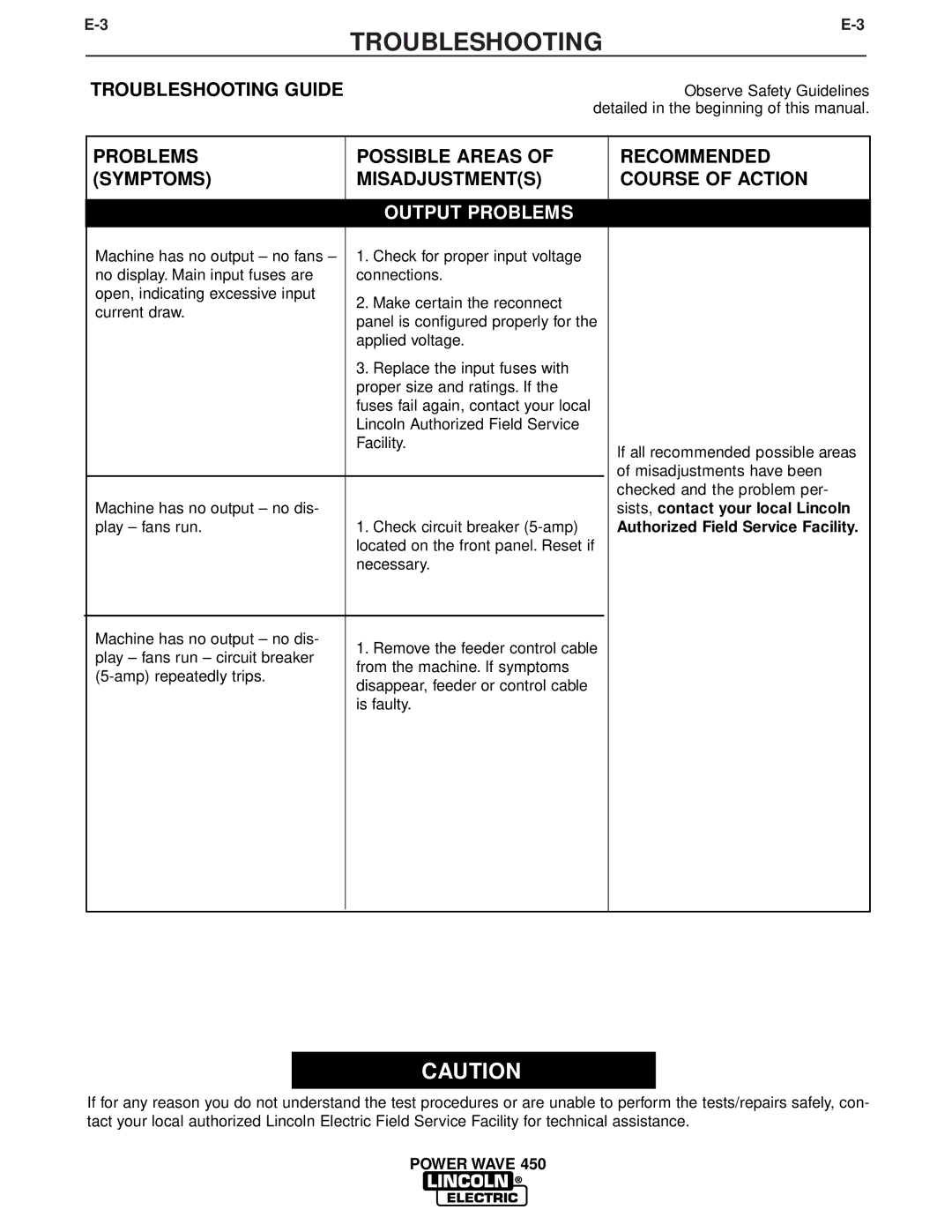

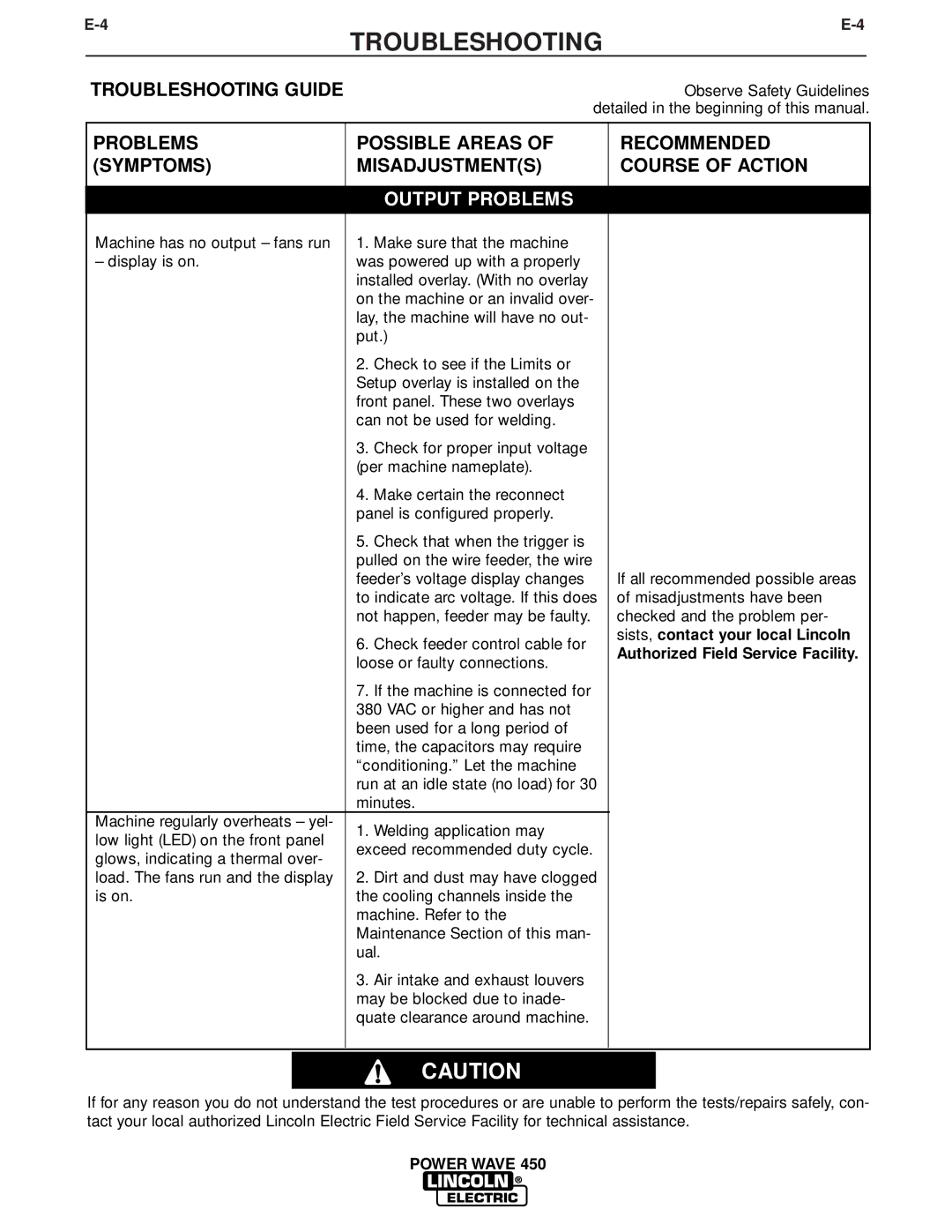

| TROUBLESHOOTING GUIDE |

|

| Observe Safety Guidelines | |

|

| detailed in the beginning of this manual. | |||

|

|

|

|

| |

| PROBLEMS | POSSIBLE AREAS OF |

| RECOMMENDED | |

| (SYMPTOMS) | MISADJUSTMENT(S) |

| COURSE OF ACTION | |

|

|

|

|

|

|

|

| OUTPUT PROBLEMS |

|

|

|

| The Beeper (Piezoelectric Buzzer) cannot be | 1. Background noise may be too loud for user |

|

|

|

| heard – machine operating normally. | to hear beeper. |

|

|

|

|

|

|

|

|

|

| The welding parameters that were | 1. Make certain that a remote control unit is |

|

|

|

| saved in memory are different | not connected. When a remote control unit is |

|

|

|

| when recalled. | used, the weld parameters are set by the |

|

|

|

|

| remote control potentiometers. |

|

|

|

|

|

|

|

|

|

| The water cooler does not turn on. | 1. Make sure that the water cooler has been |

|

|

|

| enabled. Refer to the Setup Overlay descrip- |

|

|

| |

|

|

|

|

| |

|

| tion in the Operation Section of this manual. |

|

|

|

|

| 2. If the water cooler is enabled but there is |

|

|

|

|

| insufficient pressure in the water cooler hose, |

|

|

|

|

| the machine will beep loudly and the water |

|

|

|

|

| cooler will shut down. In this case, prime the |

|

|

|

|

| water cooler. Refer to the Setup Overlay |

|

|

|

|

| description in the Operation Section of this |

|

|

|

|

| manual. |

|

|

|

|

|

|

| If all recommended possible areas | |

| The machine beeps without the | If the water cooler is enabled and the pres- |

| ||

| keys being pressed. | sure switch inside the water cooler opens (due |

| of misadjustments have been | |

|

| to inadequate pressure in the water cooler |

| checked and the problem per- | |

|

| hose), the machine indicates this by beeping. |

| sists, contact your local Lincoln | |

|

| This happens regardless of the overlay placed |

| Authorized Field Service Facility. | |

|

| on the machine. In this case do the following: |

|

|

|

|

| 1. Turn the machine off and on a couple of |

|

|

|

|

| times and see if the beeping continues. If the |

|

|

|

|

| pressure dropped momentarily then turning |

|

|

|

|

| the machine off and on eliminates the beep- |

|

|

|

|

| ing. A momentary pressure drop could be due |

|

|

|

|

| to someone stepping on the water cooler |

|

|

|

|

| hose, for example. |

|

|

|

|

| 2 Check the water cooler hose for kinks and |

|

|

|

|

| other places of reduced water flow. If such |

|

|

|

|

| problems were found then correct them and |

|

|

|

|

| turn the machine off and on to check if the |

|

|

|

|

| beeping has been eliminated. |

|

|

|

|

| 3. Check the water cooler fluid level. Low fluid |

|

|

|

|

| level could cause the pressure to drop. |

|

|

|

|

| 4. Prime the water cooler. Refer to the Setup |

|

|

|

|

| Overlay section of this manual for instructions. |

|

|

|

|

|

|

|

|

|

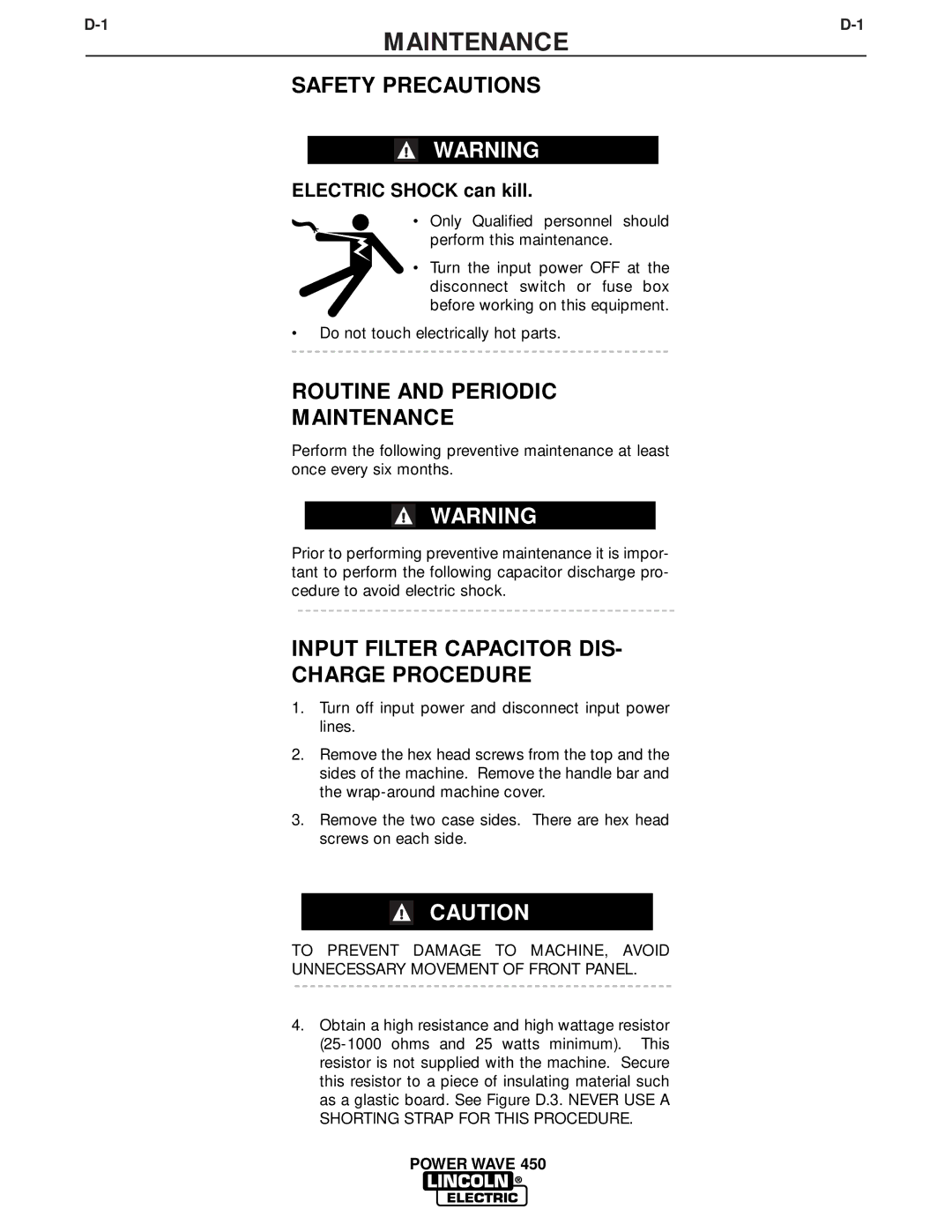

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, con- tact your local authorized Lincoln Electric Field Service Facility for technical assistance.

POWER WAVE 450