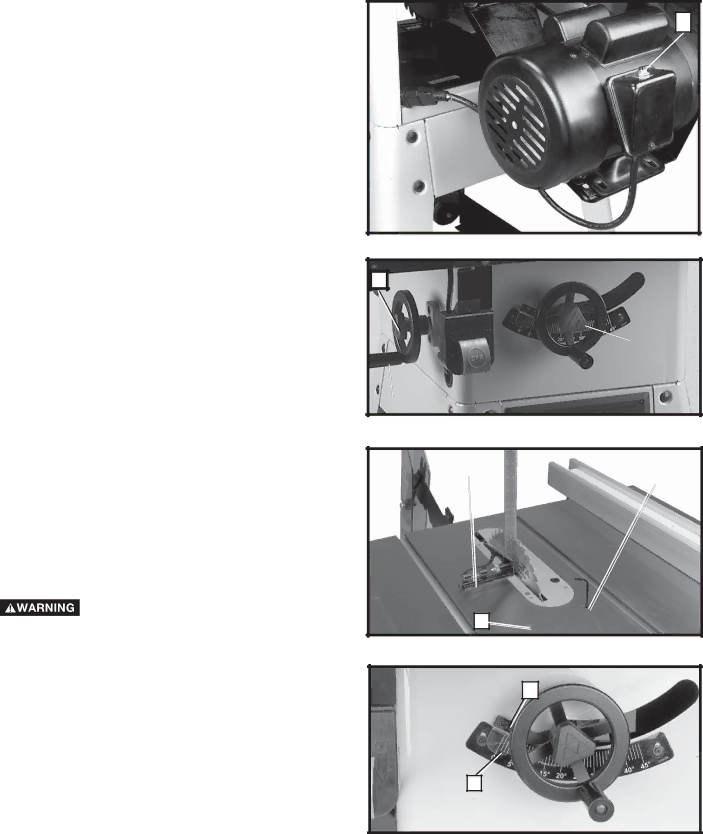

OVERLOAD PROTECTION

The motor supplied with your saw is equipped with a manual reset overload (A) Fig. 58. If the motor shuts off or fails to start due to overloading (cutting stock too fast, using a dull blade, using the saw beyond its capacity, etc.), or low voltage, move the ON/OFF switch to the “OFF” position, let the motor cool three to five minutes and push the reset button (A), which will reset the overload device. The motor can then be turned on again in the usual manner.

RAISING AND LOWERING BLADE

To raise the saw blade, loosen lock knob (C) Fig. 59, and turn the blade raising handwheel (D) clockwise. When the blade is at the desired height, tighten lock knob (C).

To lower the blade, loosen lock knob (C) and turn the handwheel (D) counterclockwise. NOTE: One full turn of the handwheel will change blade height approxi- mately 1/4".

TILTING THE BLADE

To tilt the saw blade for bevel cutting, loosen lock knob

(A)and turn the tilting handwheel (B). When the desired blade angle is obtained, tighten lock knob (A).

ADJUSTING 90 DEGREE AND 45 DEGREE POSITIVE STOPS

Your saw is equipped with positive stops that will quickly and accurately position the saw blade at 90 degrees and 45 degrees to the table. To check and adjust the positive stops, proceed as follows:

DISCONNECT MACHINE FROM

POWER SOURCE.

1.Raise the saw blade to its highest position.

2.Set the blade at 90 degrees to the table by turning the blade tilting handwheel (B) Fig. 59 counterclockwise as far as it will go.

3.Using a combination square (A) Fig. 60, check to see if the blade is at 90 degrees to the table surface as shown.

4.If the blade is not at 90 degrees to the table, move the blade off of the stop by turning the handwheel (B) Fig. 59 one turn clockwise. Loosen set screw (F) Fig. 60 with a 4mm hex wrench. Turn the blade tilting handwheel until the blade is at 90 degrees to the table. Tighten set screw (F) until it bottoms.

5.Adjust the hairline indicator (D) Fig. 61, to point to the zero degree mark on the scale by loosening screws (E), adjusting pointer (D), and tightening screws (E).

6.Turn the blade tilting handwheel clockwise as far as it will go and using a combination square, check to see if the blade is at 45 degrees to the table.

A

Fig. 58

A |

![]() C

C

![]() D

D

B

Fig. 59

AB

F

Fig. 60

E

D

Fig. 61

7.If the blade is not at 45 degrees to the table, move the blade off of the stop by turning the handwheel (B) Fig. 59 one turn

(B)Fig. 60, and turn blade tilting handwheel until the blade is 45 degrees to the table. Tighten set screw (B) until it bottoms.

22