NOTE: THE OUTSIDE ARBOR FLANGE CAN NOT BE USED WITH THE MOULDING CUTTERHEAD. TIGHTEN THE ARBOR NUT AGAINST THE CUTTERHEAD BODY. DO NOT LOSE THE OUTSIDE ARBOR FLANGE. IT WILL BE NEEDED WHEN REATTACHING A BLADE TO THE ARBOR.

ALWAYS RETURN AND FASTEN

THE BLADE GUARD AND SPLITTER ASSEMBLY TO ITS PROPER OPERATING POSITION FOR NORMAL

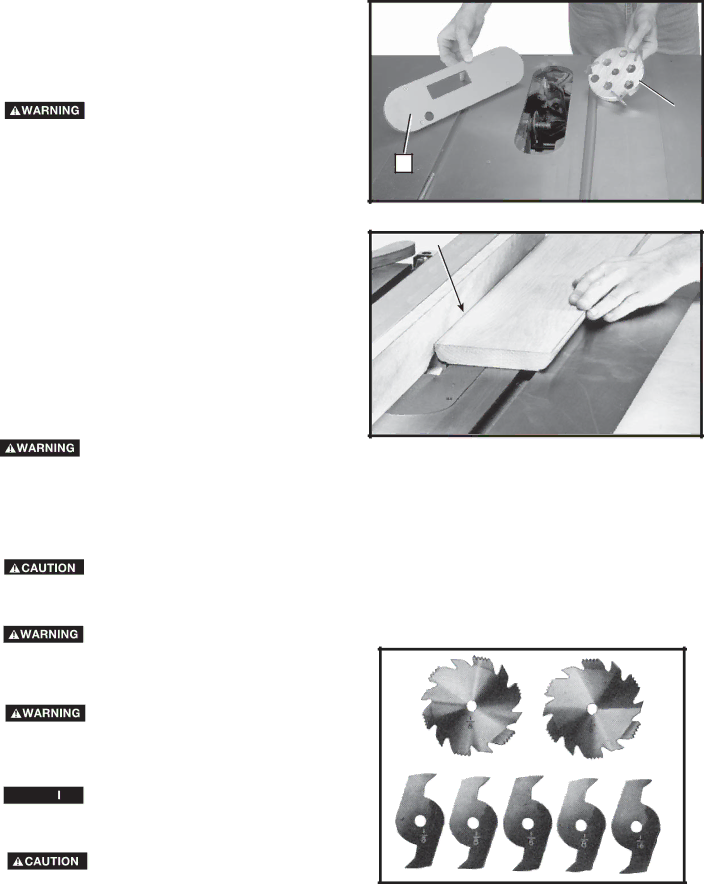

1.A moulding cutterhead (A) Fig. S15 can be easily assembled to the saw arbor. Also, the accessory moulding cutterhead table insert (B) must be used in place of the standard table insert.

2.When using the moulding cutterhead, add wood- facing (C) to the face of the rip fence (Fig. S16). The

screws through holes which must be drilled in the fence. Stock that is 3/4″ inch thick is suitable for most work, although an occasional job may require 1 inch facing.

3.Position the

NEVER USE MOULDING CUTTERHEAD

IN A BEVEL POSITION.

![]() NEVER RUN THE STOCK BETWEEN THE FENCE AND THE MOULDING CUTTERHEAD. IRREGULAR SHAPED WOOD WILL

NEVER RUN THE STOCK BETWEEN THE FENCE AND THE MOULDING CUTTERHEAD. IRREGULAR SHAPED WOOD WILL

CAUSE KICKBACK.

SPECIAL ATTENTION SHOULD BE

GIVEN THE GRAIN DIRECTION. MAKE ALL CUTS IN THE SAME DIRECTION AS THE GRAIN WHENEVER POSSIBLE.

ALWAYS INSTALL BLADE GUARD

AFTER OPERATION IS COMPLETE.

USING ACCESSORY DADO HEAD

THE BLADE GUARD AND SPLITTER

ASSEMBLY CANNOT BE USED WHEN DADOING OR MOULDING. IT MUST BE REMOVED AS DESCRIBED IN “USING ACCESSORY MOULDING CUTTERHEAD” SECTION.

![]()

![]()

![]()

![]() USE PUSHSTICKS,

USE PUSHSTICKS,

WHEN THE GUARD CANNOT BE USED.

THE ACCESSORY DADO HEAD SET

TABLE INSERT (E) FIG. S20, MUST BE USED IN PLACE OF THE STANDARD TABLE INSERT.

A

B

Fig. S15

C

Fig. S16

Fig. S17

31