Return to Section TOC

to Section TOC

Return to Master TOC

to Master TOC

TROUBLESHOOTING & REPAIR

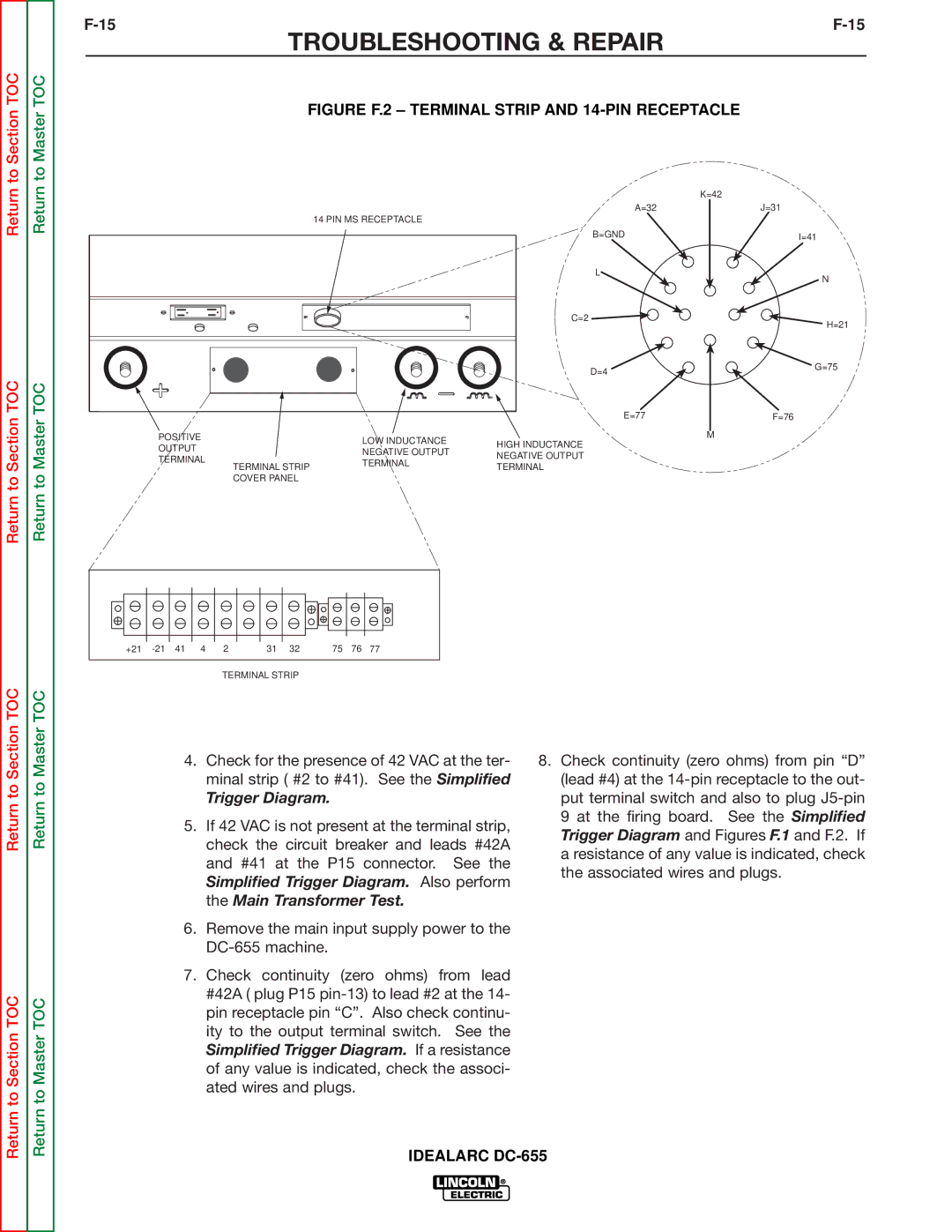

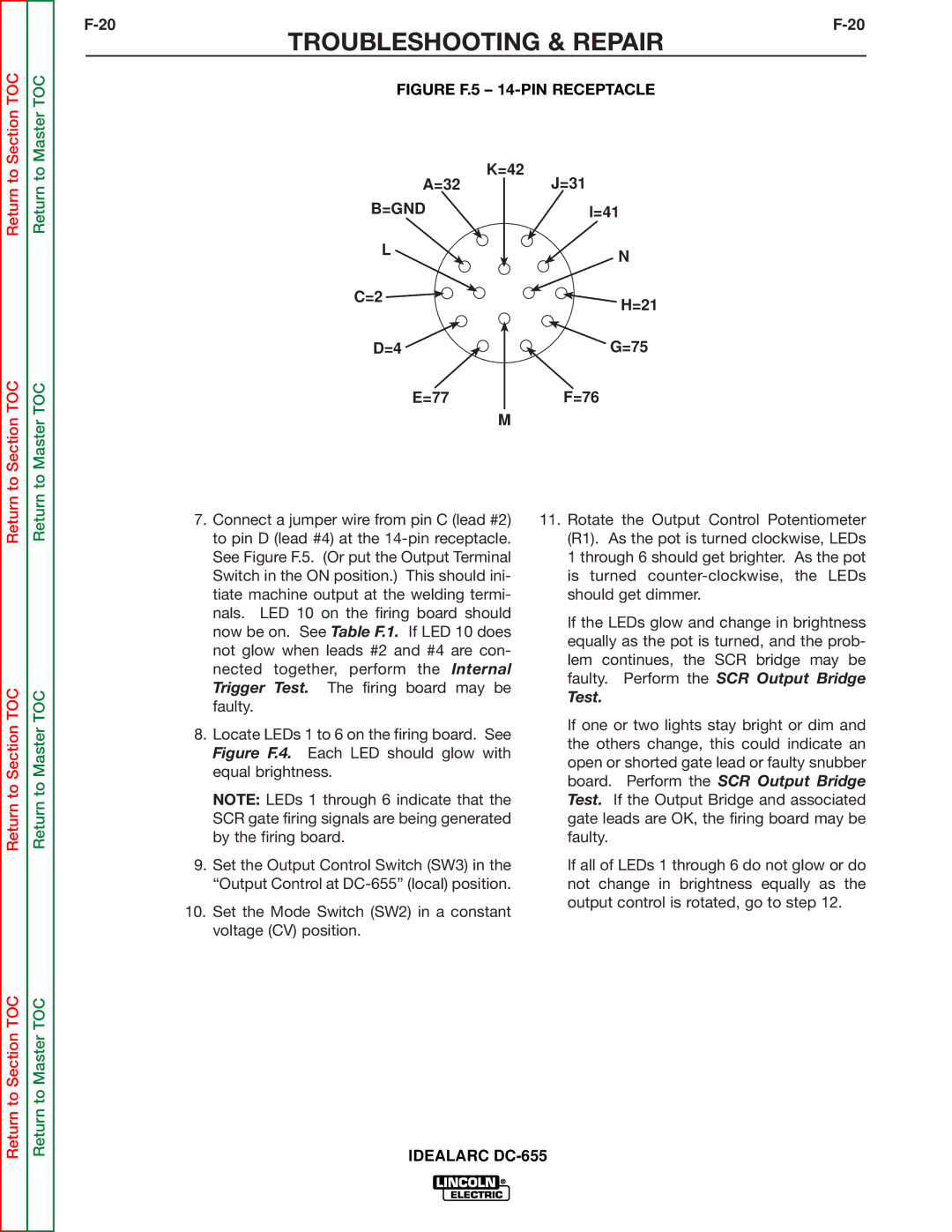

FIGURE F.5 – 14-PIN RECEPTACLE

| K=42 |

A=32 | J=31 |

B=GND | I=41 |

L | N |

| |

C=2 | H=21 |

| |

D=4 | G=75 |

E=77 | F=76 |

| M |

Return

Return to Section TOC

Return

Return to Master TOC

7.Connect a jumper wire from pin C (lead #2) to pin D (lead #4) at the

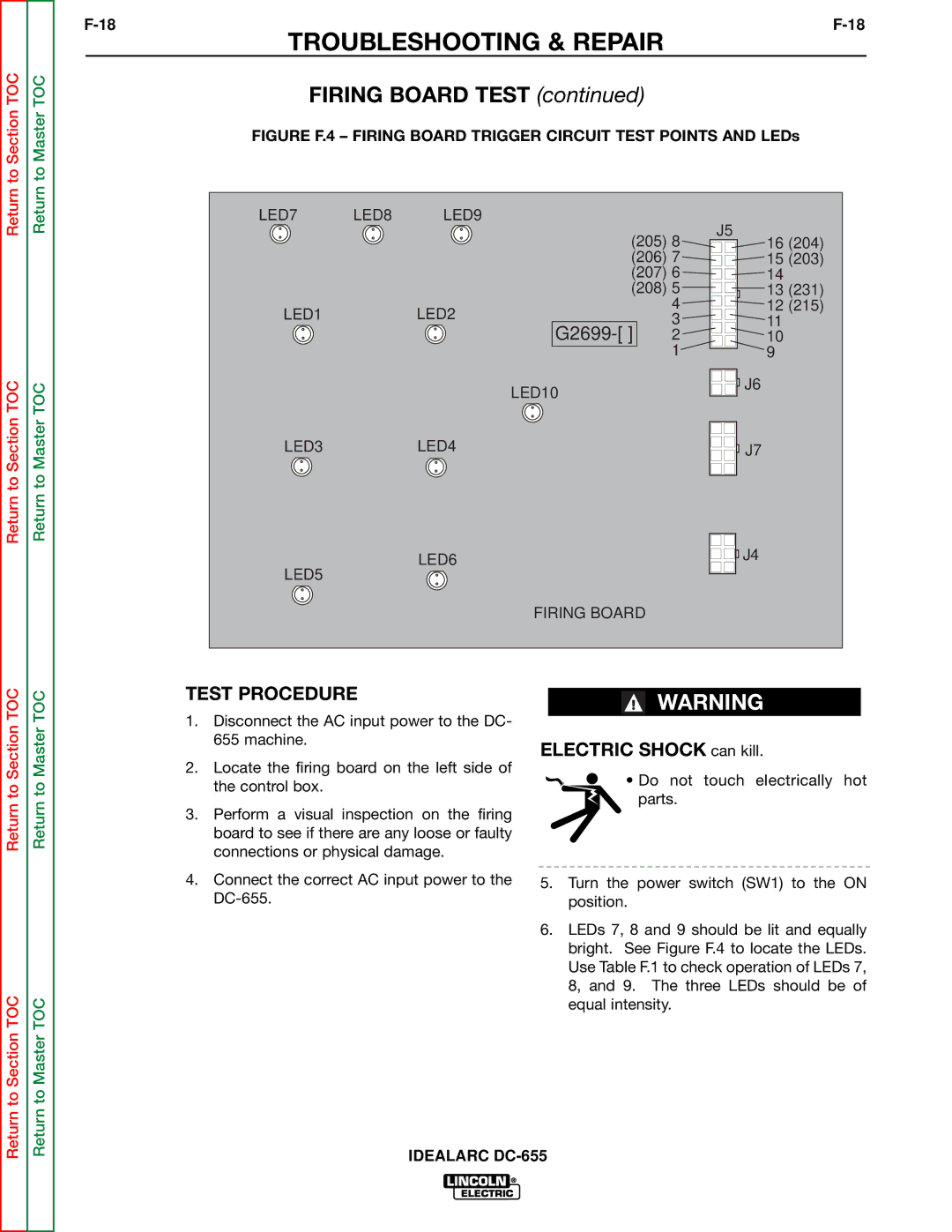

8.Locate LEDs 1 to 6 on the firing board. See Figure F.4. Each LED should glow with equal brightness.

NOTE: LEDs 1 through 6 indicate that the SCR gate firing signals are being generated by the firing board.

9.Set the Output Control Switch (SW3) in the “Output Control at

10.Set the Mode Switch (SW2) in a constant voltage (CV) position.

11.Rotate the Output Control Potentiometer (R1). As the pot is turned clockwise, LEDs 1 through 6 should get brighter. As the pot is turned

If the LEDs glow and change in brightness equally as the pot is turned, and the prob- lem continues, the SCR bridge may be faulty. Perform the SCR Output Bridge

Test.

If one or two lights stay bright or dim and the others change, this could indicate an open or shorted gate lead or faulty snubber board. Perform the SCR Output Bridge Test. If the Output Bridge and associated gate leads are OK, the firing board may be faulty.

If all of LEDs 1 through 6 do not glow or do not change in brightness equally as the output control is rotated, go to step 12.

Return to Section TOC

Return to Master TOC