Power Feed

The power feed features two feed rates; 16 FPM and 20 FPM. When running the machine, the operator can control the feed speed by moving the feed control knob. Moving the knob toward the machine produces the 20 FPM feed speed, away from the machine produces 16 FPM and a center position places the gear box in neutral.

Figure 35.

![]() CAUTION

CAUTION

The feed rate should be set while the planer is running but before feeding lumber into it. DO NOT attempt to change speeds after the cutting operation has begun.

Figure 35. Feed speed adjustment knob.

![]() CAUTION

CAUTION

If you take a cut that is too large, the planer will bog down noticeably. The motor may even stall. If this happens, turn off the power immediately, lower the table, and remove your workpiece.

Handwheel

Crank the handwheel to raise or lower the table according to the desired workpiece thickness.

Each complete revolution of the handwheel moves the table by 5/32" (4mm). Make sure the height scale is properly adjusted.

With the limiting clip installed, you cannot cut more than 1/8" in a single pass. While cutting this much material is possible, it is not recommended. Take it slow and easy. The quality of your work will be better and your planer will last longer.

Depth Limiter

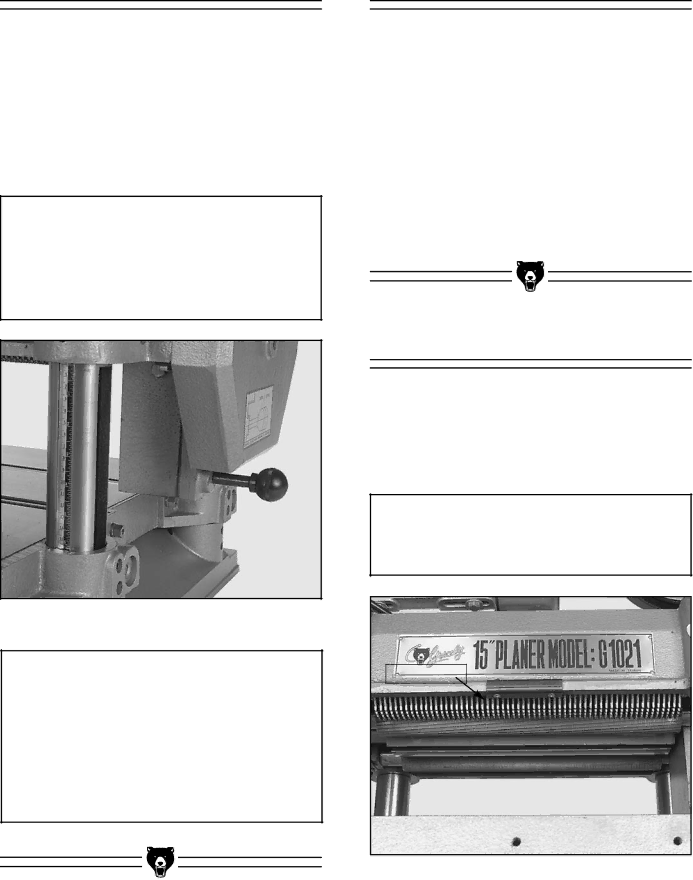

The Model G1021 is equipped with a depth lim- iter – located on the bottom of the cutterhead casting just under the nameplate. See Figure 36. The depth limiter controls maximum depth of cut to 1/8".

![]() CAUTION

CAUTION

To avoid mechanical damage to the planer, do not remove the depth limiter.

Depth Limiter