SECTION 7: MAINTENANCE

GeneralKnives

Make a habit of inspecting your planer each time you use it. Check for the following conditions and repair or replace when necessary.

1.Loose mounting bolts.

2.Worn switch.

3.Worn or damaged cords and plugs.

4.Damaged

5.Any other condition that could hamper the safe operation of this machine.

Table

The table and other

Some woodworkers recommend using automo- tive paste wax on exposed steel and cast iron surfaces. The wax provides a layer of protection, as well as reducing friction between lumber and the table, making cuts faster and smoother. Avoid waxes that contain silicone or other synthetic ingredients. These materials can find their way into lumber that’s being worked, and can make staining and finishing difficult. If you use paste wax, make sure that it’s 100% Carnauba wax.

We recommend that dull knives be taken to a pro- fessional knife sharpener. Improperly sharpened knives can cause a number of defects to lumber and put unnecessary load on the motor and drive systems. If you can avoid sharpening knives yourself, allow them to be handled by a trained sharpener.

If you must do the job yourself, take note of the following information.

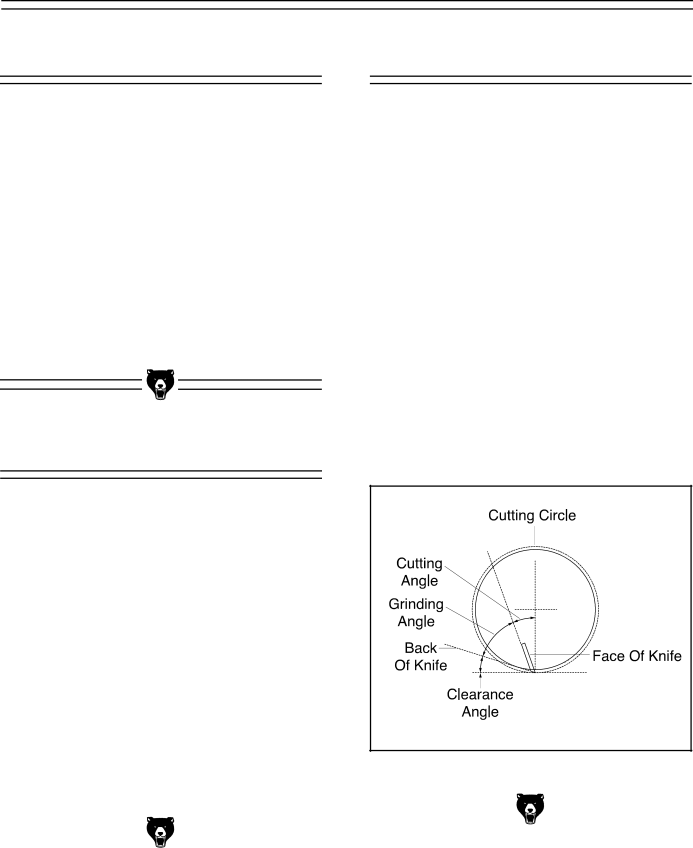

You will be dealing with a cutting angle of 35 degrees and a grinding angle of 35 degrees. See Figure 39. The grinding angle has been deter- mined by the factory to be the best compromise for planing a wide variety of wood types. In most cases, that angle will produce excellent work. If you choose to change the angle of your bevel, be sure to consult with a trained sharpener, or with a reference book before you commit to changing the angle of bevel.

Figure 39. Recommended sharpening angles.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G1021 15" Planer | ||||||