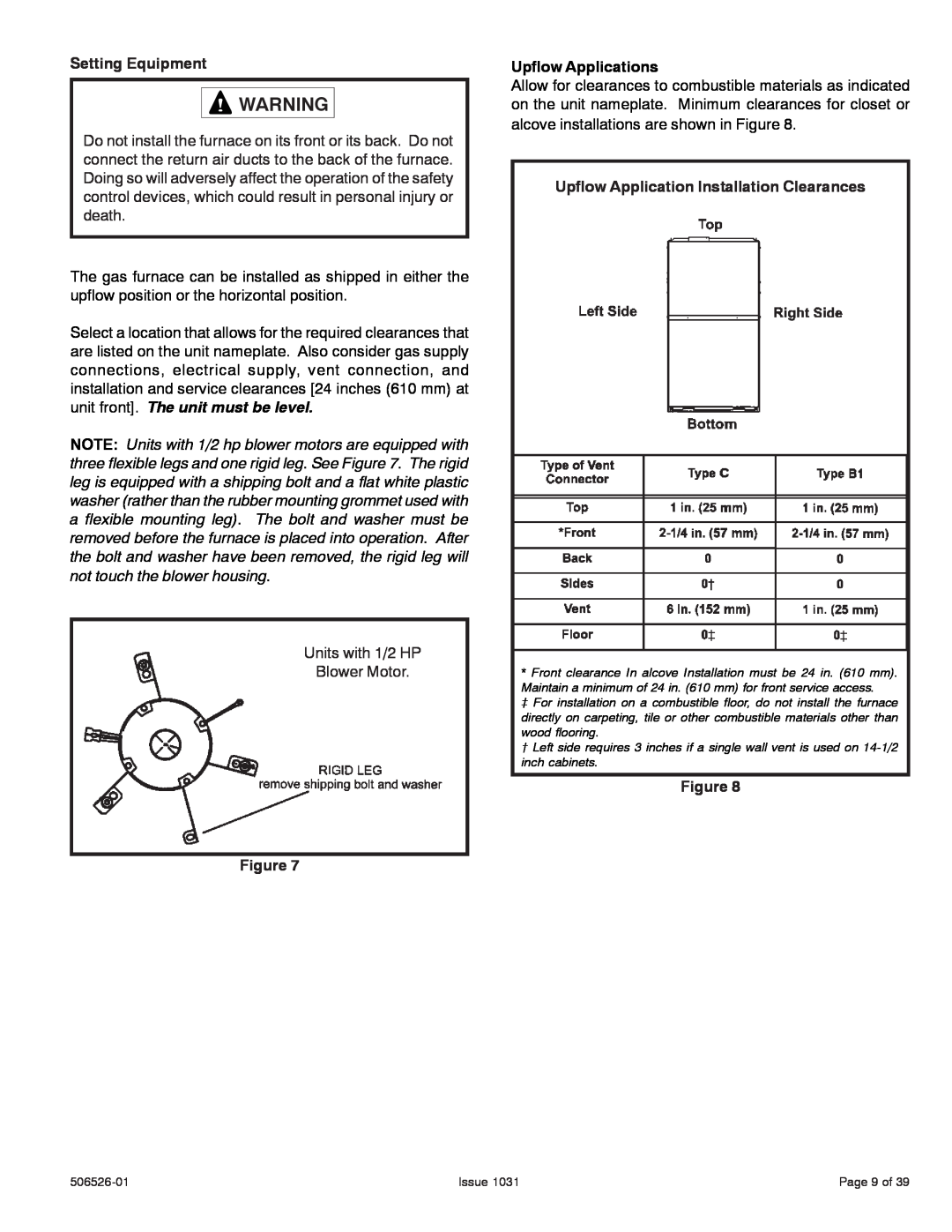

Removing the Bottom Panel

Remove the two screws that secure the bottom cap to the furnace. Pivot the bottom cap down to release the bottom panel. Once the bottom panel has been removed, reinstall the bottom cap. See Figure 11.

Removing the Bottom Panel

Figure 11

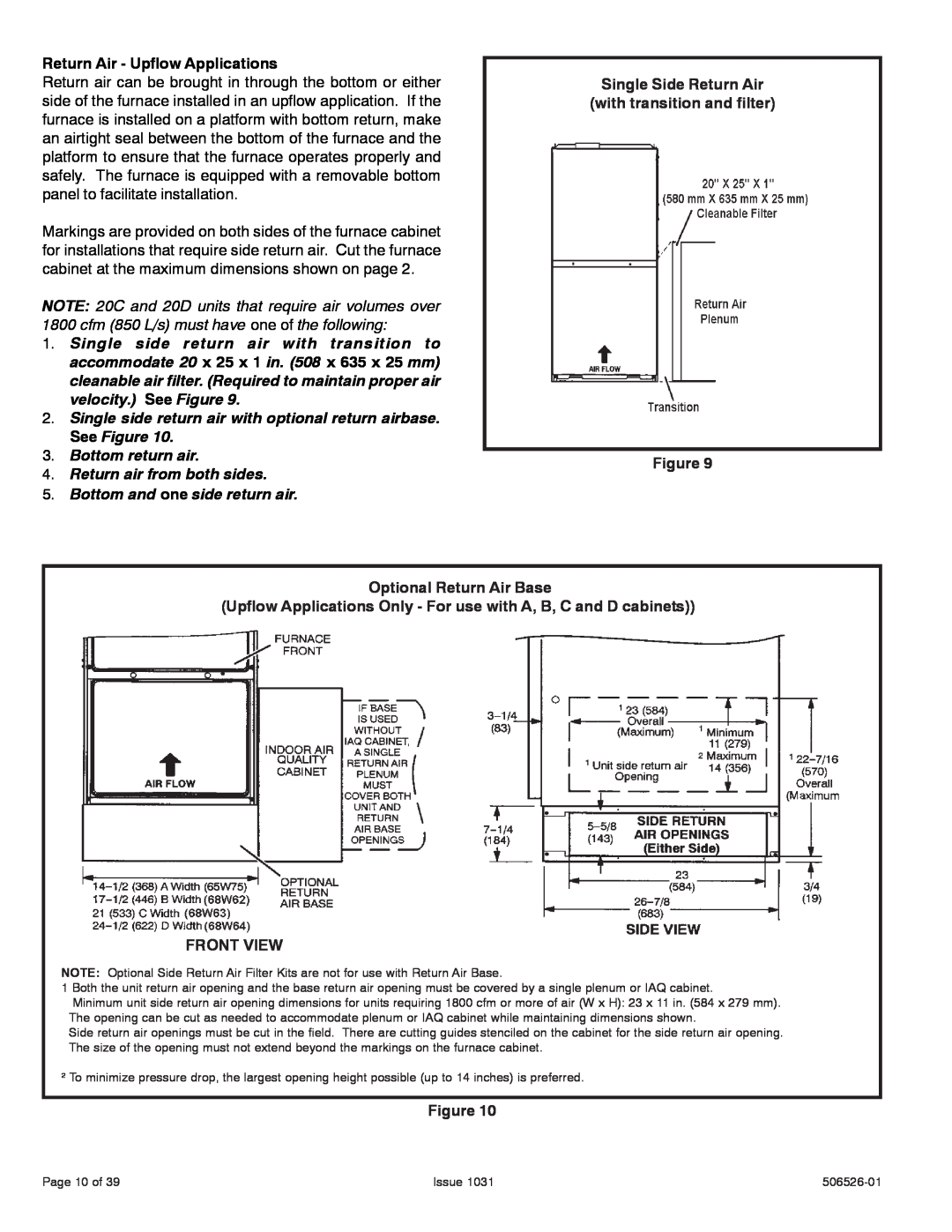

Horizontal Application

Installatioin clearances

*Front clearance in alcove installation must be 24 in. (610 mm). Maintain a minimum of 21 in. (610 mm) for front service access.

‡ For installations on a combustible floor, do not install the furnace directly on carpeting, tile or other combustible materials other than wood flooring.

Figure 12

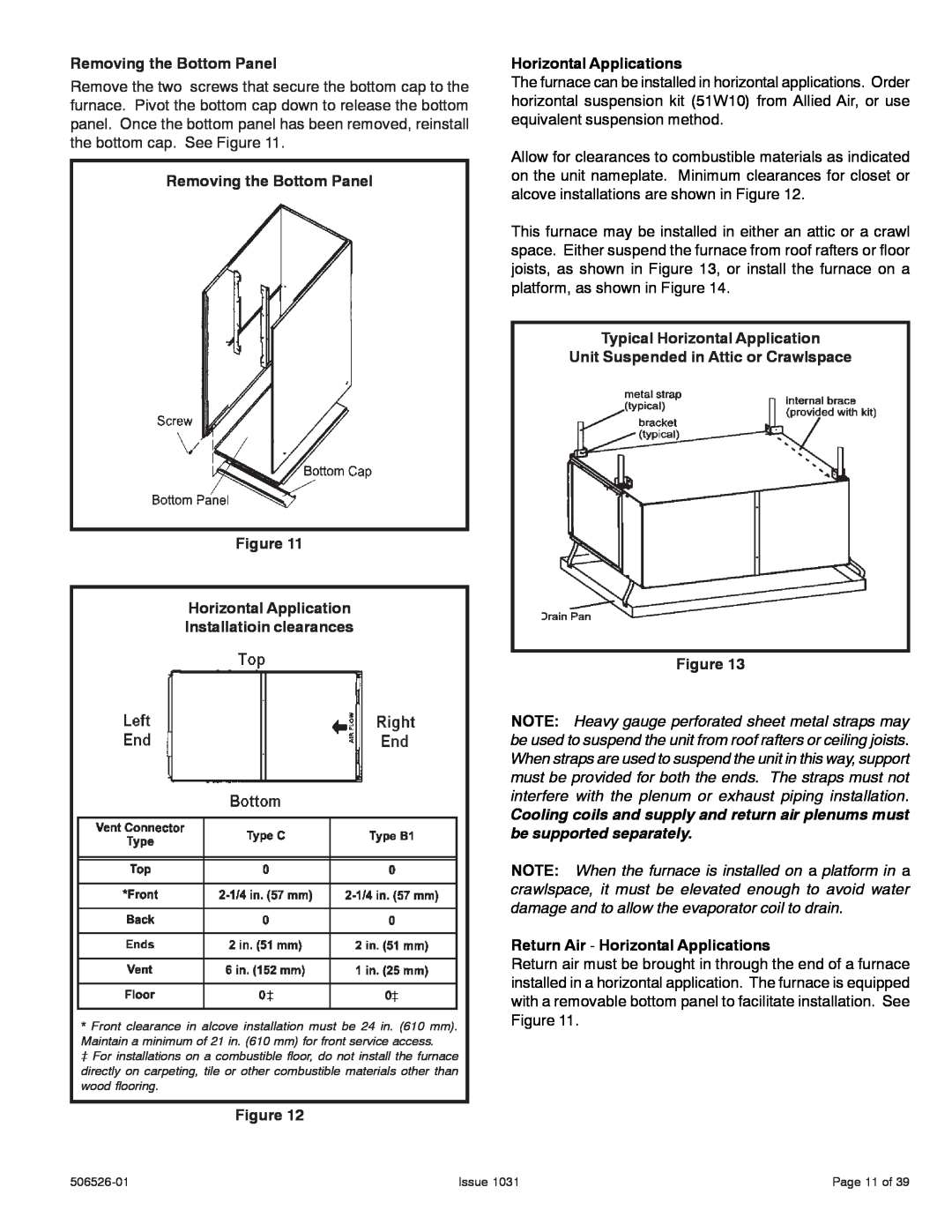

Horizontal Applications

The furnace can be installed in horizontal applications. Order horizontal suspension kit (51W10) from Allied Air, or use equivalent suspension method.

Allow for clearances to combustible materials as indicated on the unit nameplate. Minimum clearances for closet or alcove installations are shown in Figure 12.

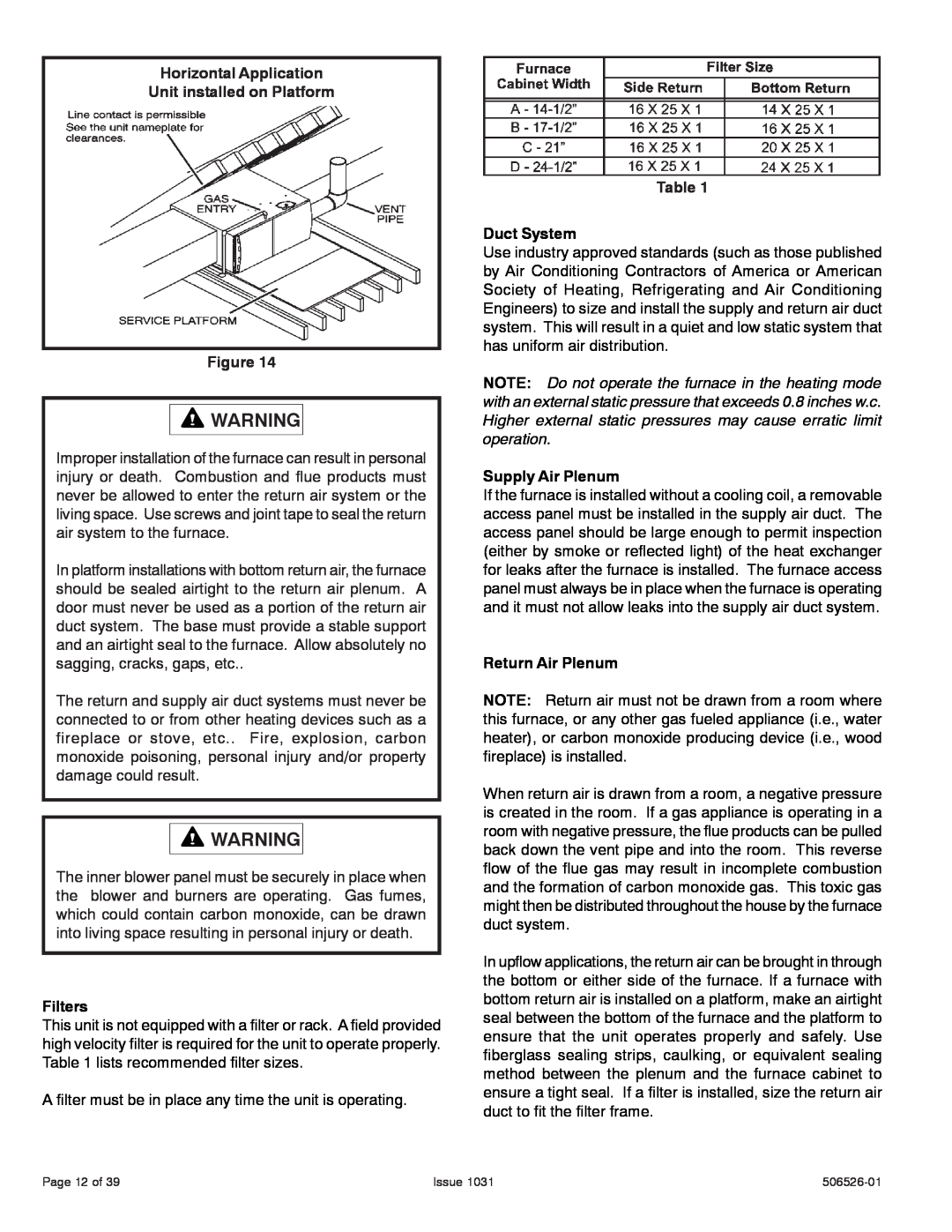

This furnace may be installed in either an attic or a crawl space. Either suspend the furnace from roof rafters or floor joists, as shown in Figure 13, or install the furnace on a platform, as shown in Figure 14.

Typical Horizontal Application

Unit Suspended in Attic or Crawlspace

Figure 13

NOTE: Heavy gauge perforated sheet metal straps may be used to suspend the unit from roof rafters or ceiling joists. When straps are used to suspend the unit in this way, support must be provided for both the ends. The straps must not interfere with the plenum or exhaust piping installation.

Cooling coils and supply and return air plenums must be supported separately.

NOTE: When the furnace is installed on a platform in a crawlspace, it must be elevated enough to avoid water damage and to allow the evaporator coil to drain.

Return Air - Horizontal Applications

Return air must be brought in through the end of a furnace installed in a horizontal application. The furnace is equipped with a removable bottom panel to facilitate installation. See Figure 11.

Issue 1031 | Page 11 of 39 |