Use, Maintenance, and Care of the Devices

Electrostatic Discharge

Electrostatic Discharge

Protection against ESD (electrostatic discharge) is essential while connecting, inspecting, or cleaning connectors attached to a

Static electricity can build up on your body and can easily damage sensitive internal circuit elements when discharged. Static discharges too small to be felt can cause permanent damage. Devices such as calibration components and devices under test (DUTs), can also carry an electrostatic charge. To prevent damage to the test set, components, and devices:

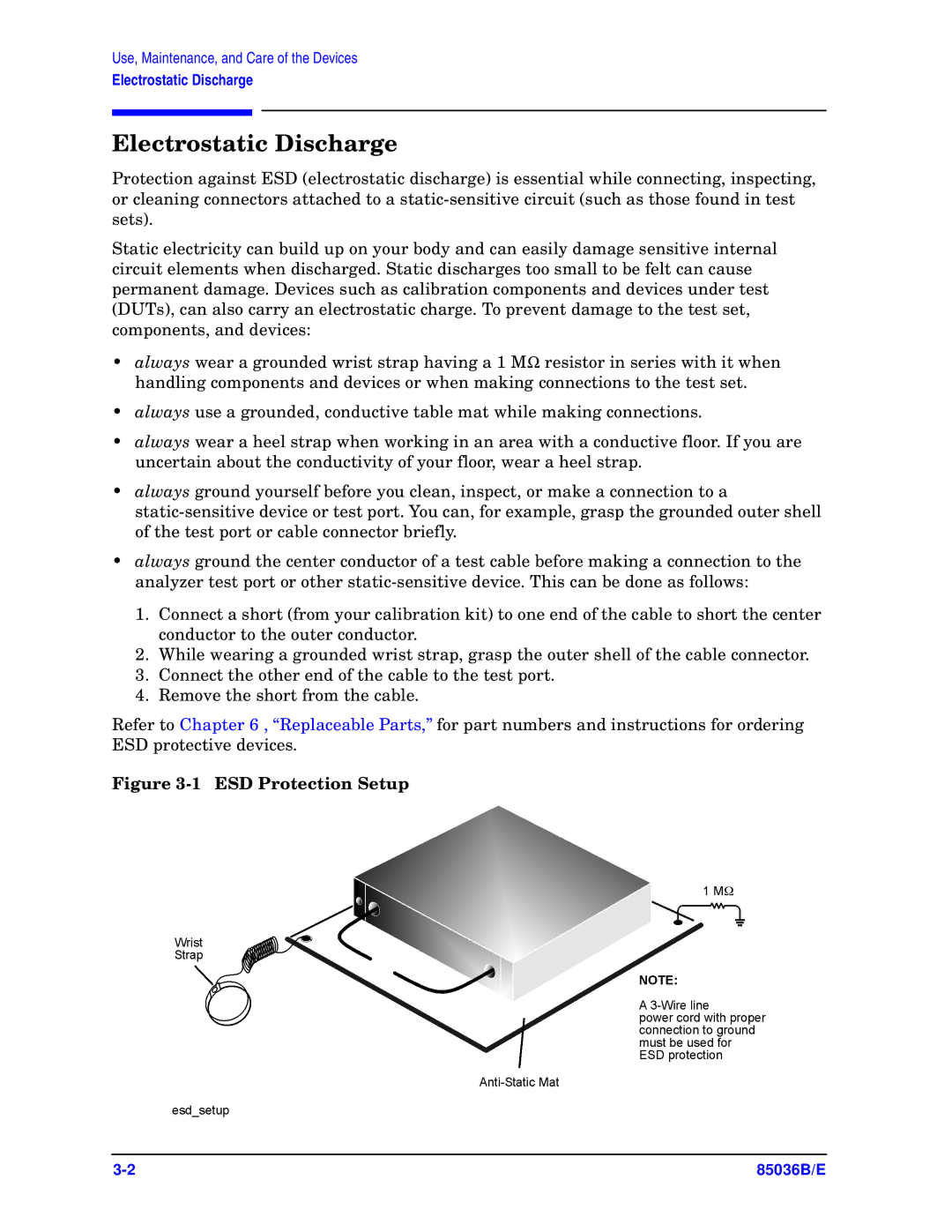

•always wear a grounded wrist strap having a 1 MΩ resistor in series with it when handling components and devices or when making connections to the test set.

•always use a grounded, conductive table mat while making connections.

•always wear a heel strap when working in an area with a conductive floor. If you are uncertain about the conductivity of your floor, wear a heel strap.

•always ground yourself before you clean, inspect, or make a connection to a

•always ground the center conductor of a test cable before making a connection to the analyzer test port or other

1.Connect a short (from your calibration kit) to one end of the cable to short the center conductor to the outer conductor.

2.While wearing a grounded wrist strap, grasp the outer shell of the cable connector.

3.Connect the other end of the cable to the test port.

4.Remove the short from the cable.

Refer to Chapter 6 , “Replaceable Parts,” for part numbers and instructions for ordering ESD protective devices.

Figure 3-1 ESD Protection Setup

85036B/E |