Use, Maintenance, and Care of the Devices

Connections

Table 3-1 Torque Wrench Information

Connector Type | Torque Setting | Torque Tolerance |

|

|

|

135 | ±13.5 | |

|

|

|

Using a torque wrench guarantees that the connection is not too tight, preventing possible connector damage. It also guarantees that all connections are equally tight each time.

2.Prevent the rotation of anything other than the connector nut that you are tightening. It may be possible to do this by hand if one of the connectors is fixed (as on a test port). In all situations, however, it is recommended that you use an

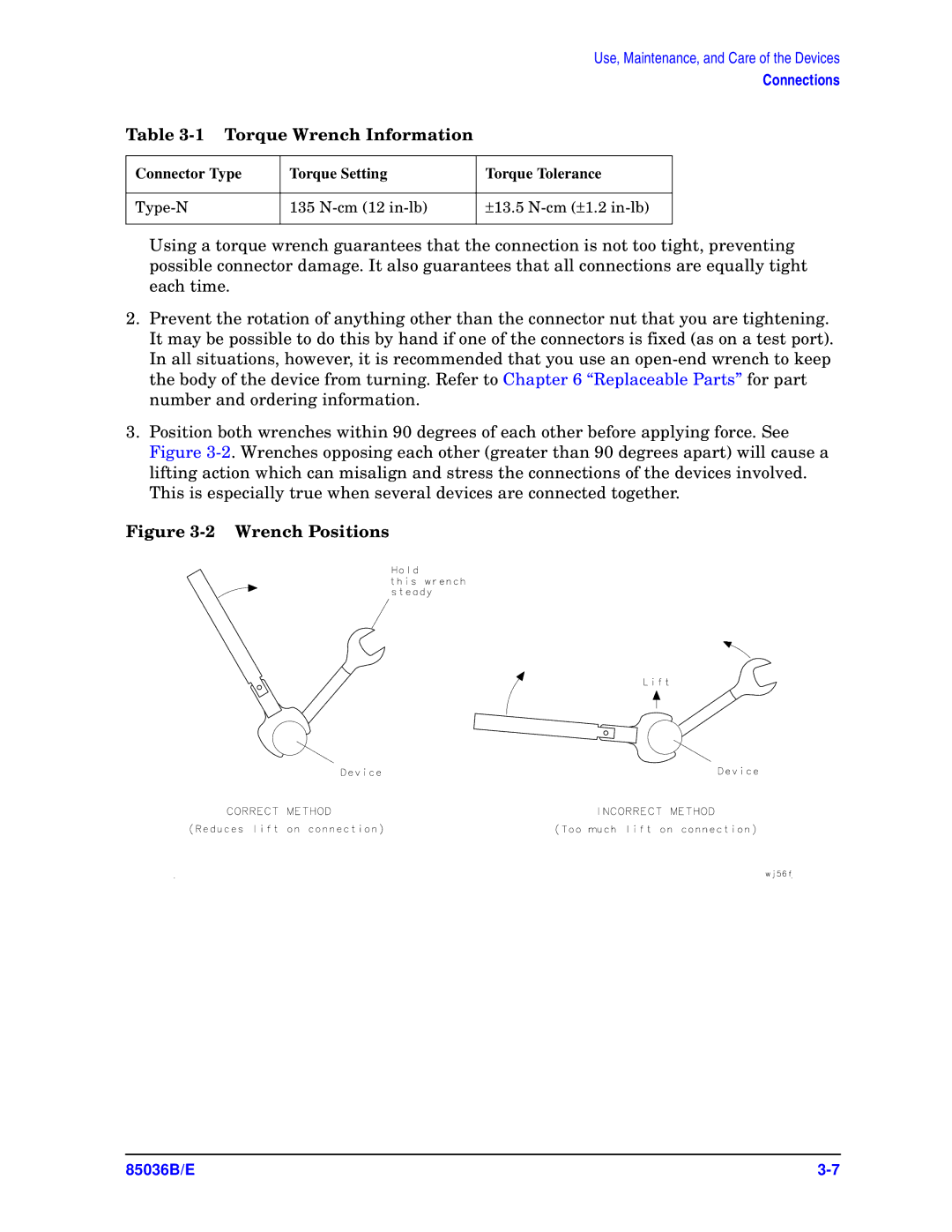

3.Position both wrenches within 90 degrees of each other before applying force. See Figure

Figure 3-2 Wrench Positions

85036B/E |