MAINTENANCE

ASSEMBLY

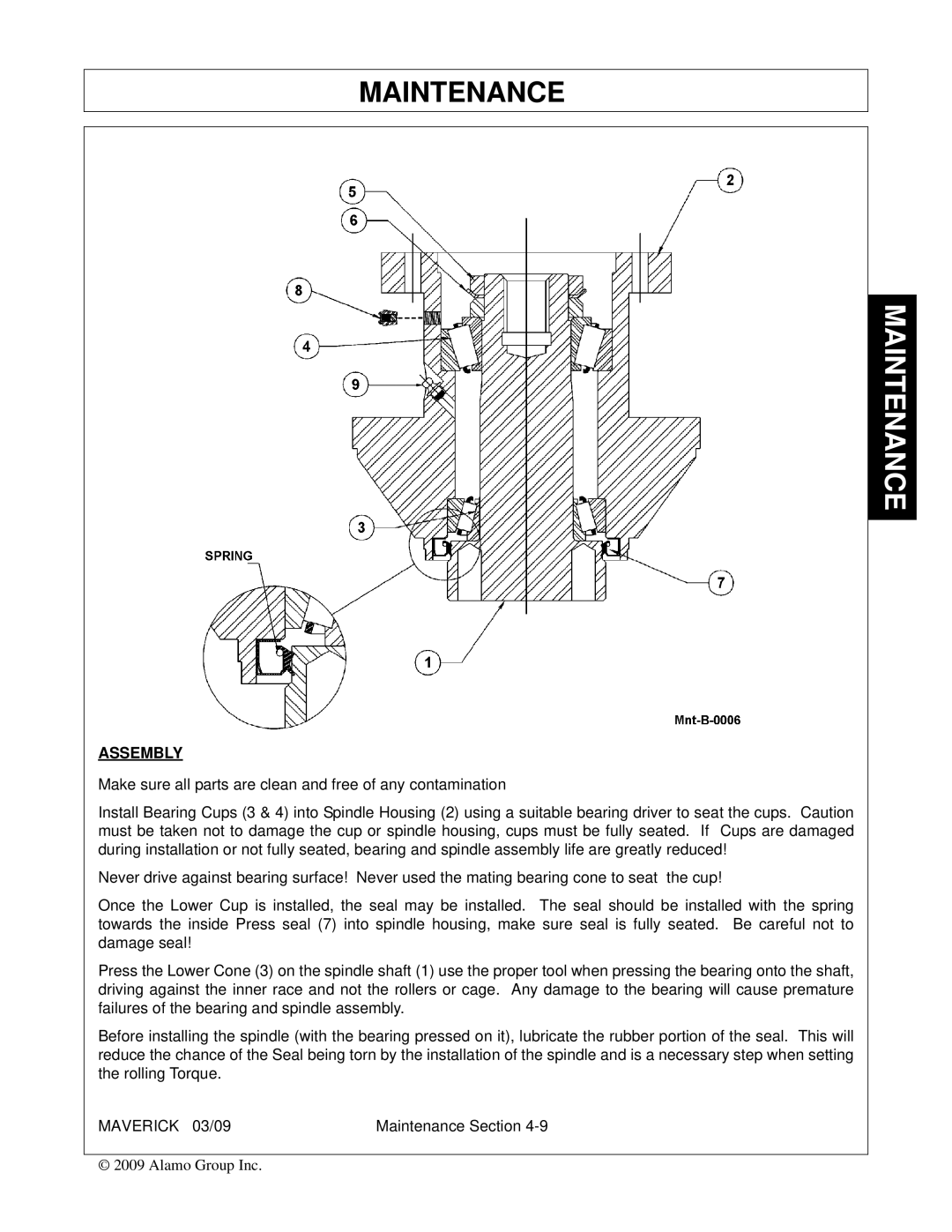

Make sure all parts are clean and free of any contamination

Install Bearing Cups (3 & 4) into Spindle Housing (2) using a suitable bearing driver to seat the cups. Caution must be taken not to damage the cup or spindle housing, cups must be fully seated. If Cups are damaged during installation or not fully seated, bearing and spindle assembly life are greatly reduced!

Never drive against bearing surface! Never used the mating bearing cone to seat the cup!

Once the Lower Cup is installed, the seal may be installed. The seal should be installed with the spring towards the inside Press seal (7) into spindle housing, make sure seal is fully seated. Be careful not to damage seal!

Press the Lower Cone (3) on the spindle shaft (1) use the proper tool when pressing the bearing onto the shaft, driving against the inner race and not the rollers or cage. Any damage to the bearing will cause premature failures of the bearing and spindle assembly.

Before installing the spindle (with the bearing pressed on it), lubricate the rubber portion of the seal. This will reduce the chance of the Seal being torn by the installation of the spindle and is a necessary step when setting the rolling Torque.

MAVERICK 03/09 | Maintenance Section |

© 2009 Alamo Group Inc.