MAINTENANCE

MAINTENANCE

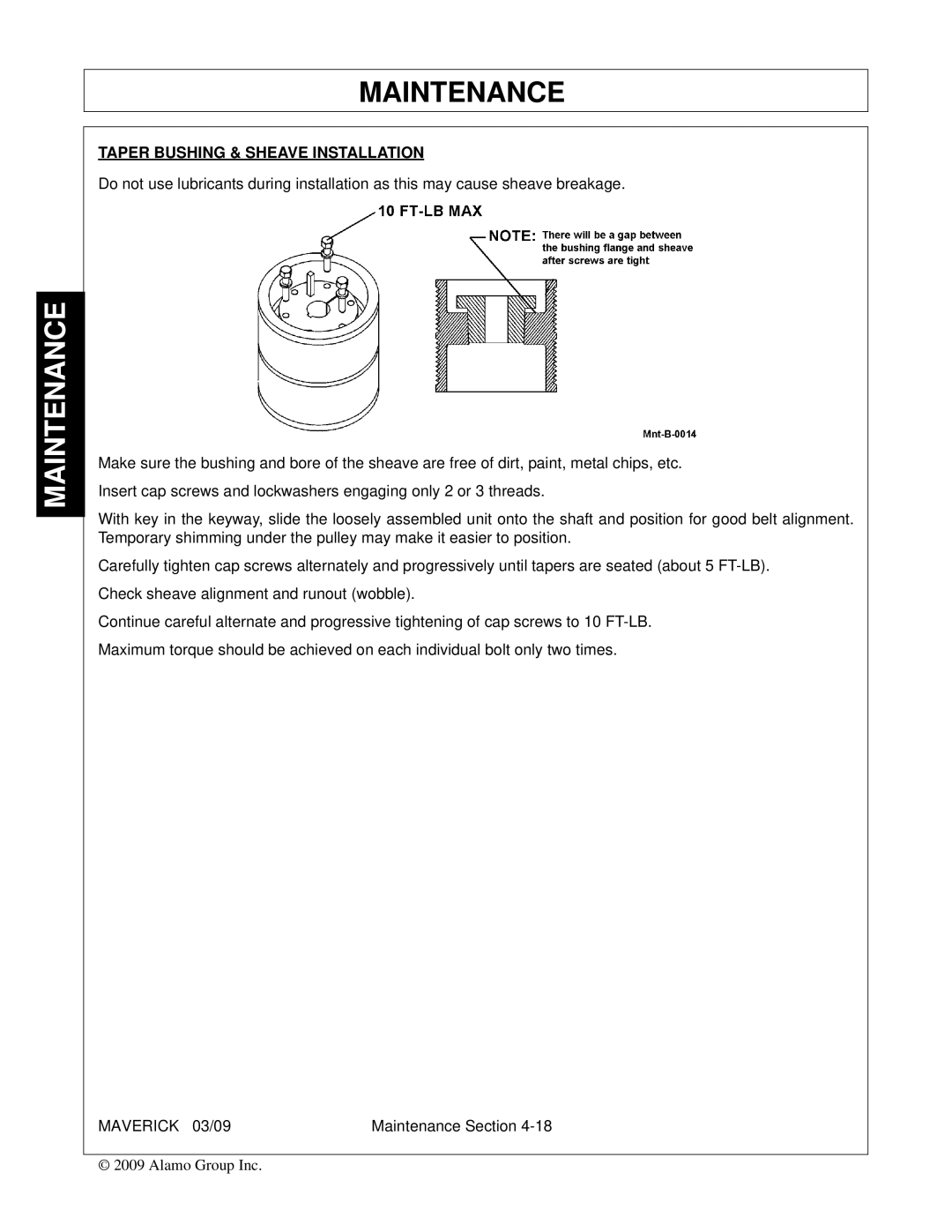

TAPER BUSHING & SHEAVE INSTALLATION

Do not use lubricants during installation as this may cause sheave breakage.

Make sure the bushing and bore of the sheave are free of dirt, paint, metal chips, etc. Insert cap screws and lockwashers engaging only 2 or 3 threads.

With key in the keyway, slide the loosely assembled unit onto the shaft and position for good belt alignment. Temporary shimming under the pulley may make it easier to position.

Carefully tighten cap screws alternately and progressively until tapers are seated (about 5

Continue careful alternate and progressive tightening of cap screws to 10

MAVERICK 03/09 | Maintenance Section |

© 2009 Alamo Group Inc.