MAINTENANCE

Lubrication:

Grease each spindle with one pump of high quality lithium grease weekly. More than one pump is unnecessary and will cause a mess when extra grease squirts out of the relief.

Grease fittings are on front of machine, just above the blades.

Belts:

Check the belt tension daily. Your buzzbar is equipped with high performance

If belts begin to slip, check tension.

To tighten the belts, loosen the four nuts that hold the spindle to the body of the machine. Then use a hand wrench or socket to turn the bolt that tensions the belt. Never use power tools to tighten belt. Once the belts begin to tighten, small adjustments will produce large changes in belt tension.

Too much tension can cause premature bearing, sheave, and belt damage.

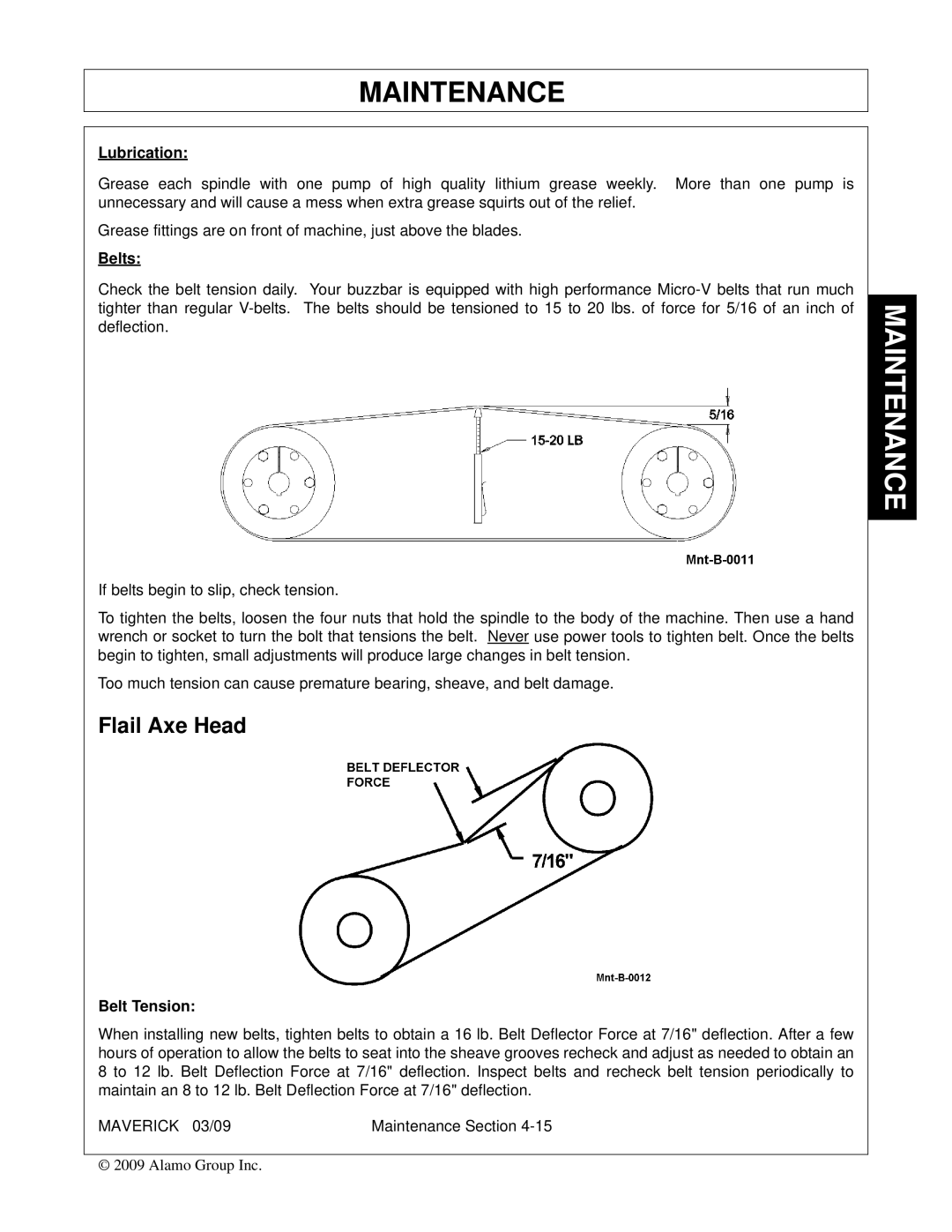

Flail Axe Head

Belt Tension:

When installing new belts, tighten belts to obtain a 16 lb. Belt Deflector Force at 7/16" deflection. After a few hours of operation to allow the belts to seat into the sheave grooves recheck and adjust as needed to obtain an 8 to 12 lb. Belt Deflection Force at 7/16" deflection. Inspect belts and recheck belt tension periodically to maintain an 8 to 12 lb. Belt Deflection Force at 7/16" deflection.

MAVERICK 03/09 | Maintenance Section |

© 2009 Alamo Group Inc.