|

| INDUCED |

|

| DRAFT BLOWER |

|

| DRAIN PORT |

|

| HOSE B |

| FRONT | HOSE A |

| COVER | |

|

| |

| PRESSURE |

|

| TAP | GREEN HOSE |

|

| |

|

| CLAMPS |

|

| (3 PLACES) |

LEFT SIDE | FRONT COVER | TUBE(S) 2 |

PANEL |

| |

| DRAIN PORT |

|

| RED HOSE CLAMP | DRAIN TRAP |

SIDE PANEL

GROMMET

HOLES

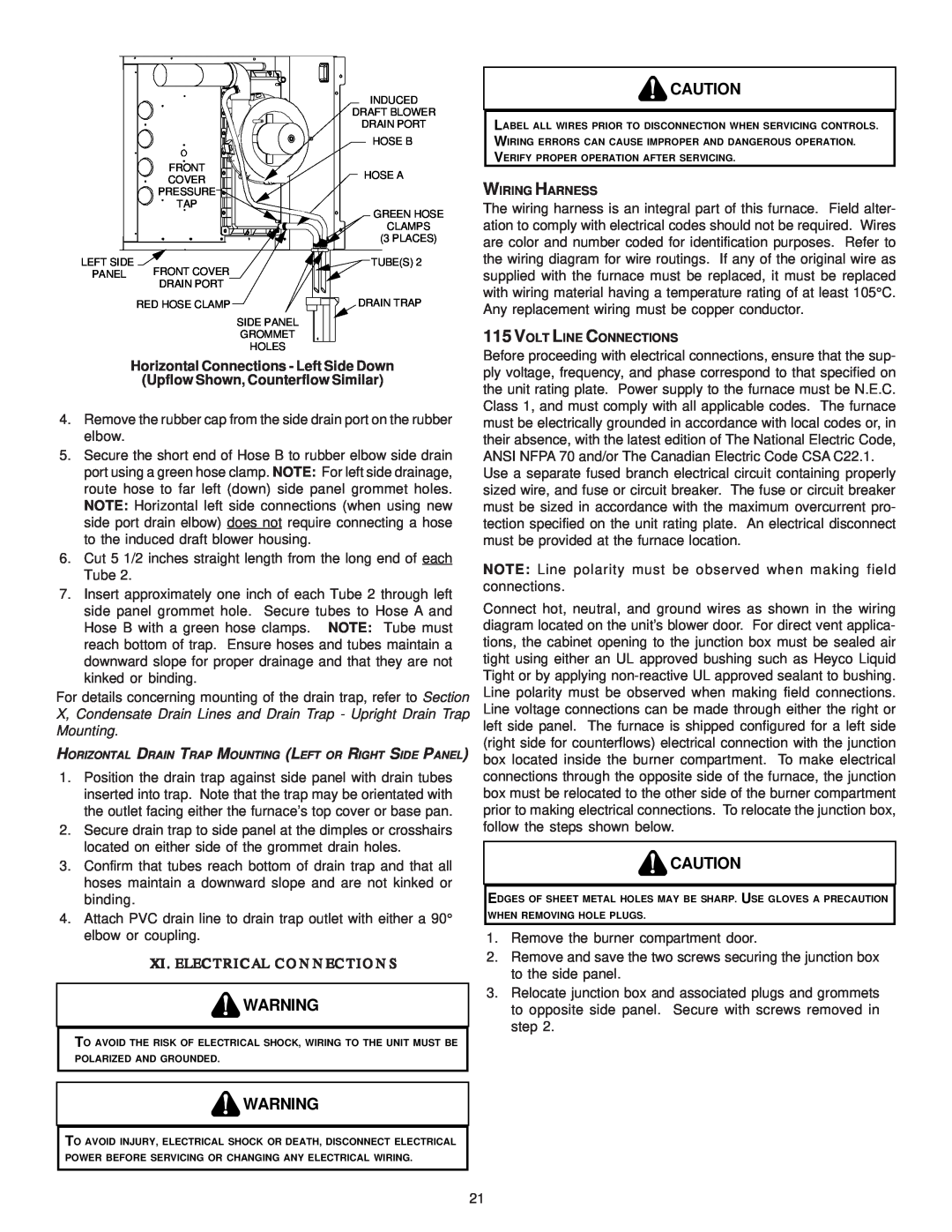

Horizontal Connections - Left Side Down

(Upflow Shown, Counterflow Similar)

4.Remove the rubber cap from the side drain port on the rubber elbow.

5.Secure the short end of Hose B to rubber elbow side drain port using a green hose clamp. NOTE: For left side drainage, route hose to far left (down) side panel grommet holes. NOTE: Horizontal left side connections (when using new side port drain elbow) does not require connecting a hose to the induced draft blower housing.

6.Cut 5 1/2 inches straight length from the long end of each Tube 2.

7.Insert approximately one inch of each Tube 2 through left side panel grommet hole. Secure tubes to Hose A and Hose B with a green hose clamps. NOTE: Tube must reach bottom of trap. Ensure hoses and tubes maintain a downward slope for proper drainage and that they are not kinked or binding.

For details concerning mounting of the drain trap, refer to Section X, Condensate Drain Lines and Drain Trap - Upright Drain Trap Mounting.

HORIZONTAL DRAIN TRAP MOUNTING (LEFT OR RIGHT SIDE PANEL)

1.Position the drain trap against side panel with drain tubes inserted into trap. Note that the trap may be orientated with the outlet facing either the furnace’s top cover or base pan.

2.Secure drain trap to side panel at the dimples or crosshairs located on either side of the grommet drain holes.

3.Confirm that tubes reach bottom of drain trap and that all hoses maintain a downward slope and are not kinked or binding.

4.Attach PVC drain line to drain trap outlet with either a 90° elbow or coupling.

XI. ELECTRICAL CONNECTIONS

![]() WARNING

WARNING

TO AVOID THE RISK OF ELECTRICAL SHOCK, WIRING TO THE UNIT MUST BE POLARIZED AND GROUNDED.

![]() CAUTION

CAUTION

LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS. WIRING ERRORS CAN CAUSE IMPROPER AND DANGEROUS OPERATION. VERIFY PROPER OPERATION AFTER SERVICING.

WIRING HARNESS

The wiring harness is an integral part of this furnace. Field alter- ation to comply with electrical codes should not be required. Wires are color and number coded for identification purposes. Refer to the wiring diagram for wire routings. If any of the original wire as supplied with the furnace must be replaced, it must be replaced with wiring material having a temperature rating of at least 105°C. Any replacement wiring must be copper conductor.

115 VOLT LINE CONNECTIONS

Before proceeding with electrical connections, ensure that the sup- ply voltage, frequency, and phase correspond to that specified on the unit rating plate. Power supply to the furnace must be N.E.C. Class 1, and must comply with all applicable codes. The furnace must be electrically grounded in accordance with local codes or, in their absence, with the latest edition of The National Electric Code, ANSI NFPA 70 and/or The Canadian Electric Code CSA C22.1.

Use a separate fused branch electrical circuit containing properly sized wire, and fuse or circuit breaker. The fuse or circuit breaker must be sized in accordance with the maximum overcurrent pro- tection specified on the unit rating plate. An electrical disconnect must be provided at the furnace location.

NOTE: Line polarity must be observed when making field connections.

Connect hot, neutral, and ground wires as shown in the wiring diagram located on the unit’s blower door. For direct vent applica- tions, the cabinet opening to the junction box must be sealed air tight using either an UL approved bushing such as Heyco Liquid Tight or by applying

![]() CAUTION

CAUTION

EDGES OF SHEET METAL HOLES MAY BE SHARP. USE GLOVES A PRECAUTION WHEN REMOVING HOLE PLUGS.

1.Remove the burner compartment door.

2.Remove and save the two screws securing the junction box to the side panel.

3.Relocate junction box and associated plugs and grommets to opposite side panel. Secure with screws removed in step 2.

![]() WARNING

WARNING

TO AVOID INJURY, ELECTRICAL SHOCK OR DEATH, DISCONNECT ELECTRICAL POWER BEFORE SERVICING OR CHANGING ANY ELECTRICAL WIRING.

21