Top Motorized Gas Valve

The valve sets the gas rate of 2,800,000 btu/hr (705,588 kcal/hr). To achieve this rate, the has pressure must be set for

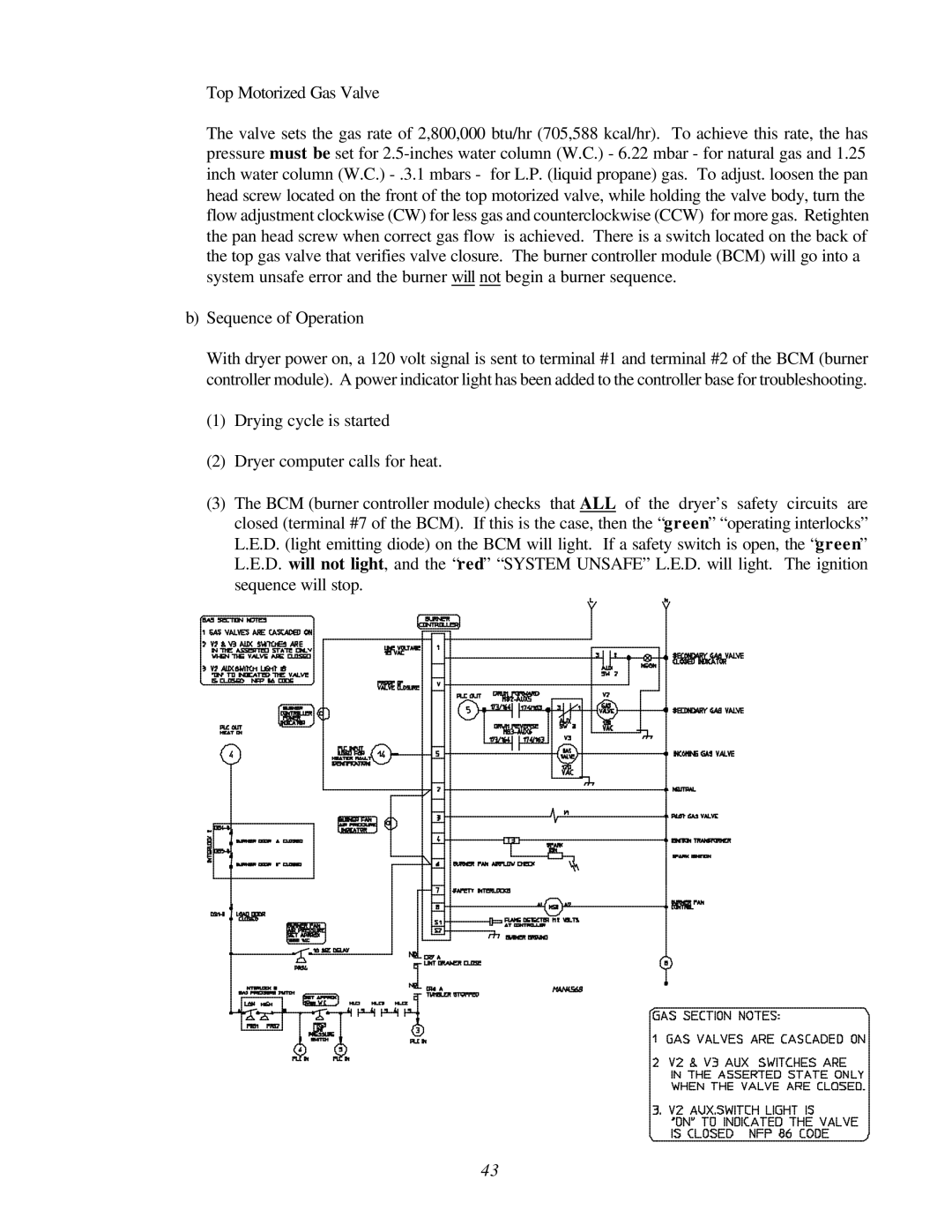

b)Sequence of Operation

With dryer power on, a 120 volt signal is sent to terminal #1 and terminal #2 of the BCM (burner controller module). A power indicator light has been added to the controller base for troubleshooting.

(1)Drying cycle is started

(2)Dryer computer calls for heat.

(3)The BCM (burner controller module) checks that ALL of the dryer’s safety circuits are closed (terminal #7 of the BCM). If this is the case, then the “green” “operating interlocks” L.E.D. (light emitting diode) on the BCM will light. If a safety switch is open, the “green” L.E.D. will not light, and the “red” “SYSTEM UNSAFE” L.E.D. will light. The ignition sequence will stop.

43