REV. E

American Panel Corporation

E-mail service@americanpanel.com

USER’S MANUAL

INSTALLATION OF REMOTE UNITS

CONTROLLER FEATURES

REQUIREMENTS TO BE MET DURING INSTALLATION 8 STEPS

INSTALLATION AT THE SAME LEVEL

MAINTENANCE

PREPARING AND USING THE OPTIONAL PRINTER

MAINTENANCE AND CLEANING

CLEANING THE CONDENSER

OPERATING MODES

CONTROLLER FEATURES

INTRODUCTION

PC CONNECTION OPTIONAL

OPERATING CYCLES

PRINTER OPTIONAL

REQUIREMENTS TO BE MET DURING INSTALLATION 8 STEPS

INSTALLATION OF REMOTE UNITS

INSTALLATION AT THE SAME LEVEL

COMPRESSOR

CONNECTION PIPING FOR REMOTE CONDENSING UNITS

INSTALLATION AT DIFFERENT LEVELS

INSTALLATION

INSTALLATION

DIMENSIONS

WARNINGS

ELECTRICAL AND REFRIGERATION SPECIFICATIONS

VERIFYING CORRECT INSTALLATION

CONNECTION TO THE REMOTE UNIT

CONDENSATE DRAINAGE CONNECTION

SPACES AROUND THE CABINET

STARTING & TESTING THE UNIT

BLAST CHILLING

USING THE HURRICHILL TECHNOLOGY

SHOCK FREEZING

SOFT CHILL CYCLE

LOADING

PANNING AND LOADING

PANNING

CONTROL PANEL FOR MODELS AP24 & AP40 BLAST CHILLERS / SHOCK FREEZERS

KEY COMBINATIONS

KEYBOARD KEYS

ON/OFF & START/STOP

PROGRAMMING KEYS

If the entered password is wrong the display will show

c. Enter the default password by pressing, in order, the

PROGRAMMING

1. INITIAL PROGRAMMING

The high food alarm temperature should be left at

The high air alarm temperature should be left at

The low air alarm temperature should be left at

The P.C. baud rate should be left at

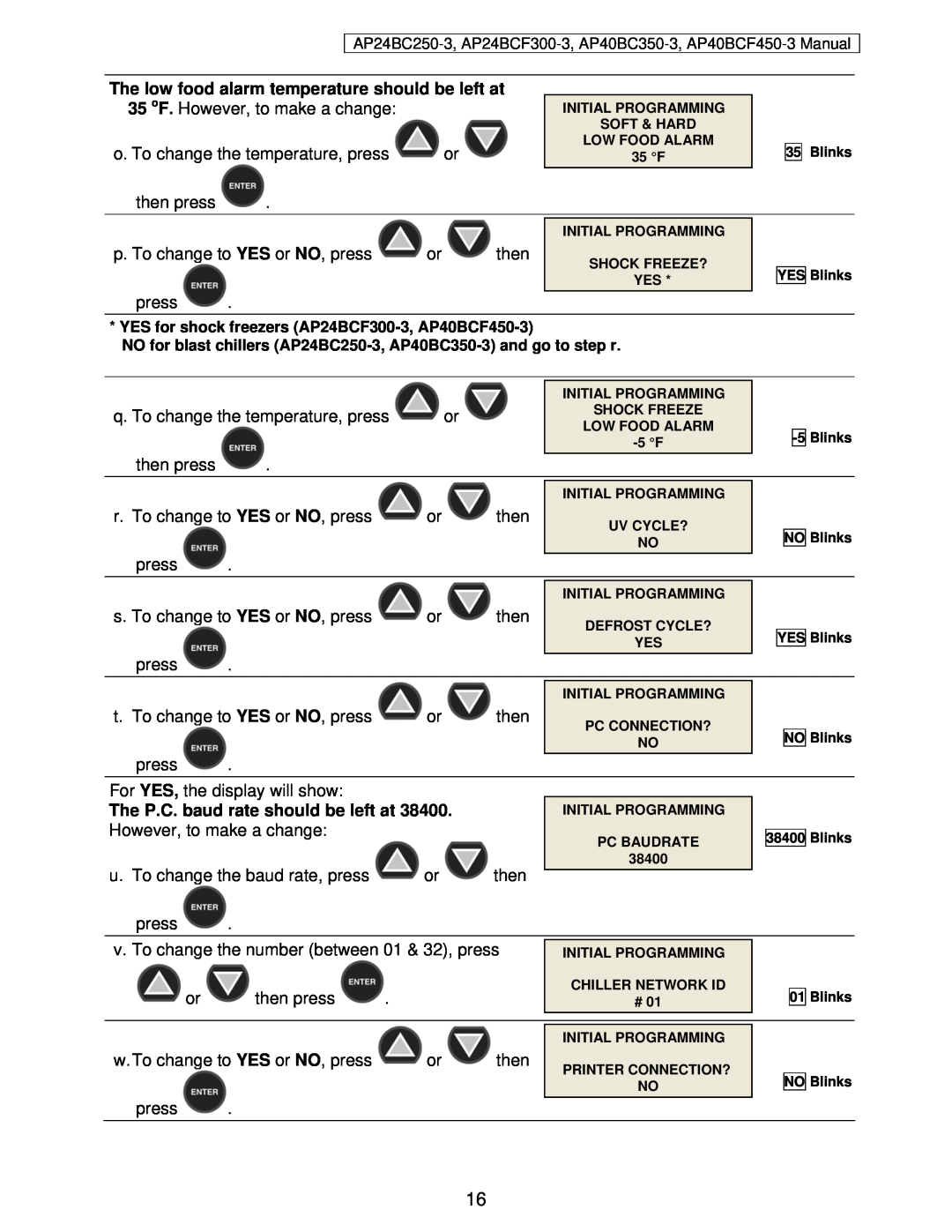

The low food alarm temperature should be left at

YES for shock freezers AP24BCF300-3, AP40BCF450-3

NO for blast chillers AP24BC250-3, AP40BC350-3 and go to step r

2. PROGRAMMING THE CYCLES

AUTOMATIC HARD CYCLE PARAMETERS PROGRAMMING

AUTOMATIC SOFT CYCLE PARAMETERS PROGRAMMING

k. To change the temperature, press

AUTOMATIC SHOCK CYCLE PARAMETERS PROGRAMMING

then press

p. To change the temperature, press

UV LIGHT CYCLE PARAMETERS PROGRAMMING

HEATED PROBE CYCLE PARAMETERS PROGRAMMING

DEFROST CYCLE PARAMETERS PROGRAMMING

The defrost type must be left AIR FLOW

aa. Press

gg. Press

MANUAL SOFT CYCLE PARAMETERS PROGRAMMING

The LED for SOFT will be steady

hh. To change the temperature, press

MANUAL HARD CYCLE PARAMETERS PROGRAMMING

MANUAL SHOCK CYCLE PARAMETERS PROGRAMMING

3. RECIPE NAME PROGRAMMING

1. AUTOMATIC MODE - SOFT CHILL

OPERATION

alternating

2. MANUAL MODE - SOFT CHILL

alternating with

3. HARD CHILL CYCLE

5. UV STERILIZATION CYCLE

4. SHOCK FREEZE CYCLE

6. DEFROST CYCLE

a. To perform a UV cycle remove all food, then press

b. Open the door

7. HEATED FOOD PROBE

c. Press the

defrost cycle

OTE To stop any cycle before it has finished, press START/STOP

8. PREPARING AND USING THE OPTIONAL PRINTER

NOTE The optional printer is delivered fully installed

d. Enter your password, then press

PRINTER

9. TO CLEAR DATA

LOADING A ROLL OF PAPER

MAINTENANCE

REMOVING A ROLL OF PAPER

OPERATING THE PRINTER

REPLACING THE RIBBON WITH PAPER IN THE PRINTER

MAINTENANCE AND CLEANING

CLEANING THE CONDENSER

CLEANING

WIRING DIAGRAMS

COMPARTMENT

DO NOT USE ABRASIVES, SOLVENTS

AP24BC250-3, AP24BCF300-3, AP40BC350-3, AP40BCF450-3 Manual

AP24BC250-3, AP24BCF300-3, AP40BC350-3, AP40BCF450-3 Manual

AP24BC250-3, AP24BCF300-3, AP40BC350-3, AP40BCF450-3 Manual

COMPUTER CONNECTION

DESCRIPTION

PARTS LIST

PART #

installing contractor. It is not covered by this Warranty

STANDARD WARRANTY

AMERICAN PANEL CORP

BLAST CHILLERS / SHOCK FREEZERS ONLY

ORDERING PRINTER SUPPLIES RIBBON & PAPER