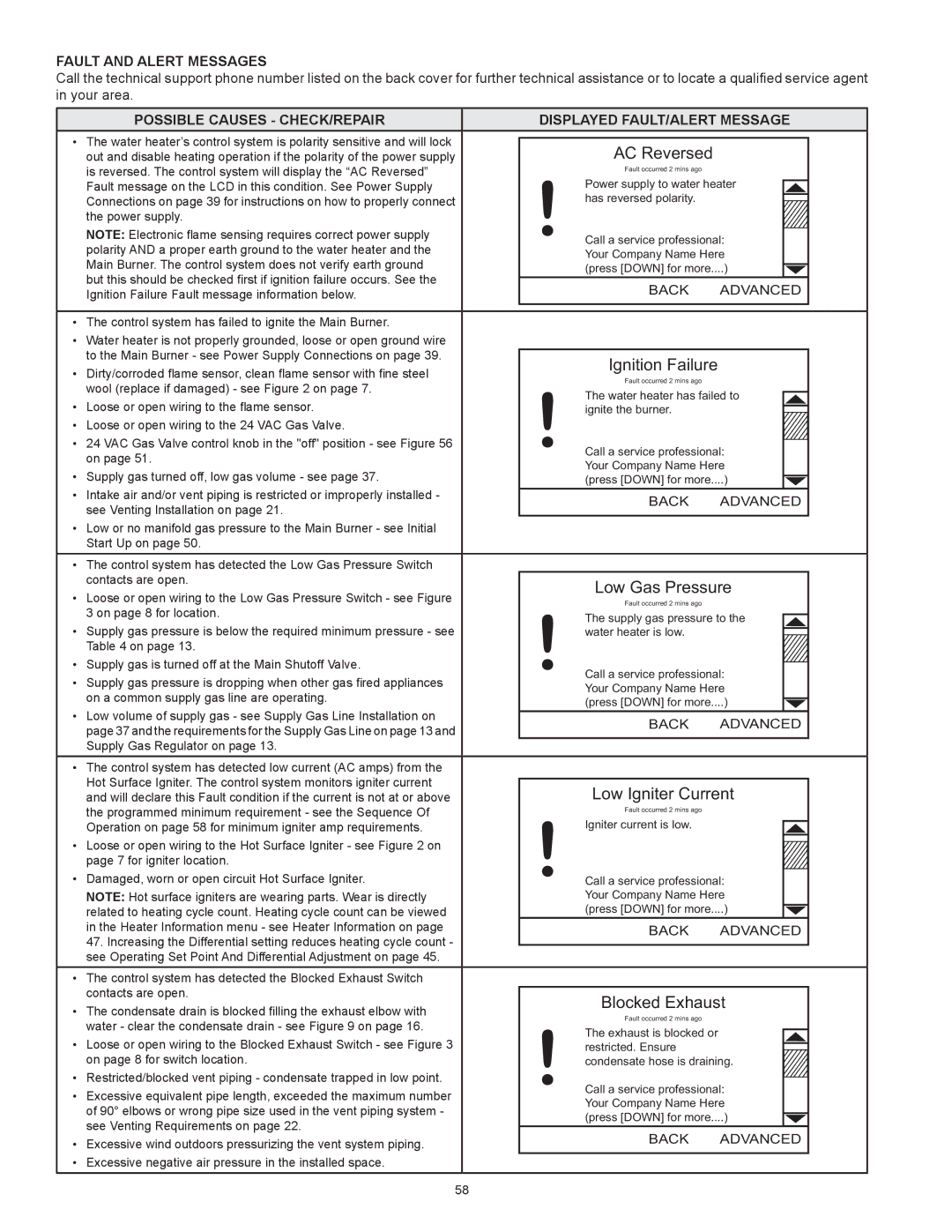

Fault And Alert Messages

Call the technical support phone number listed on the back cover for further technical assistance or to locate a qualified service agent in your area.

Possible Causes - Check/Repair | Displayed Fault/Alert Message | ||||

• The water heater’s control system is polarity sensitive and will lock |

|

|

|

|

|

| AC Reversed |

|

|

| |

out and disable heating operation if the polarity of the power supply |

|

|

|

| |

is reversed. The control system will display the “AC Reversed” |

| Fault occurred 2 mins ago |

|

|

|

|

|

|

|

| |

Fault message on the LCD in this condition. See Power Supply | Power supply to water heater |

|

| ||

|

| ||||

Connections on page 39 for instructions on how to properly connect | has reversed polarity. |

|

|

| |

|

|

| |||

the power supply. |

|

|

|

|

|

Note: Electronic flame sensing requires correct power supply | Call a service professional: |

|

| ||

polarity AND a proper earth ground to the water heater and the |

|

| |||

Your Company Name Here |

|

| |||

Main Burner. The control system does not verify earth ground |

|

| |||

(press [DOWN] for more....) |

|

| |||

|

| ||||

but this should be checked first if ignition failure occurs. See the |

|

|

|

|

|

CHANGE | BACK | ADVANCED |

| ||

Ignition Failure Fault message information below. |

| ||||

• The control system has failed to ignite the Main Burner. |

|

|

|

|

|

• Water heater is not properly grounded, loose or open ground wire |

|

|

|

|

|

to the Main Burner - see Power Supply Connections on page 39. |

| Ignition Failure |

|

|

|

• Dirty/corroded flame sensor, clean flame sensor with fine steel |

|

|

|

| |

| Fault occurred 2 mins ago |

|

|

| |

wool (replace if damaged) - see Figure 2 on page 7. |

|

|

|

| |

The water heater has failed to |

|

| |||

• Loose or open wiring to the flame sensor. |

|

| |||

ignite the burner. |

|

|

| ||

|

|

| |||

• Loose or open wiring to the 24 VAC Gas Valve. |

|

|

|

|

|

• 24 VAC Gas Valve control knob in the "off" position - see Figure 56 | Call a service professional: |

|

| ||

on page 51. |

|

| |||

Your Company Name Here |

|

| |||

• Supply gas turned off, low gas volume - see page 37. |

|

| |||

(press [DOWN] for more....) |

|

| |||

|

| ||||

• Intake air and/or vent piping is restricted or improperly installed - | CHANGE | BACK | ADVANCED |

| |

see Venting Installation on page 21. |

| ||||

|

|

|

|

| |

• Low or no manifold gas pressure to the Main Burner - see Initial |

|

|

|

|

|

Start Up on page 50. |

|

|

|

|

|

• The control system has detected the Low Gas Pressure Switch |

|

|

|

|

|

contacts are open. | Low Gas Pressure |

| |||

• Loose or open wiring to the Low Gas Pressure Switch - see Figure |

| ||||

| Fault occurred 2 mins ago |

|

|

| |

3 on page 8 for location. | The supply gas pressure to the |

|

| ||

|

| ||||

• Supply gas pressure is below the required minimum pressure - see |

|

| |||

water heater is low. |

|

|

| ||

|

|

| |||

Table 4 on page 13. |

|

|

|

|

|

• Supply gas is turned off at the Main Shutoff Valve. | Call a service professional: |

|

| ||

• Supply gas pressure is dropping when other gas fired appliances |

|

| |||

Your Company Name Here |

|

| |||

on a common supply gas line are operating. |

|

| |||

(press [DOWN] for more....) |

|

| |||

|

| ||||

• Low volume of supply gas - see Supply Gas Line Installation on |

|

|

|

|

|

CHANGE | BACK | ADVANCED |

| ||

page 37 and the requirements for the Supply Gas Line on page 13 and |

| ||||

|

|

|

|

| |

Supply Gas Regulator on page 13. |

|

|

|

|

|

• The control system has detected low current (AC amps) from the |

|

|

|

|

|

Hot Surface Igniter. The control system monitors igniter current |

|

|

|

|

|

Low Igniter Current |

| ||||

and will declare this Fault condition if the current is not at or above |

| ||||

the programmed minimum requirement - see the Sequence Of |

| Fault occurred 2 mins ago |

|

|

|

|

|

|

|

| |

Operation on page 58 for minimum igniter amp requirements. | Igniter current is low. |

|

|

| |

|

|

| |||

• Loose or open wiring to the Hot Surface Igniter - see Figure 2 on |

|

|

|

|

|

page 7 for igniter location. |

|

|

|

|

|

• Damaged, worn or open circuit Hot Surface Igniter. | Call a service professional: |

|

| ||

Note: Hot surface igniters are wearing parts. Wear is directly | Your Company Name Here |

|

| ||

related to heating cycle count. Heating cycle count can be viewed | (press [DOWN] for more....) |

|

| ||

in the Heater Information menu - see Heater Information on page | CHANGE | BACK | ADVANCED |

| |

47. Increasing the Differential setting reduces heating cycle count - |

|

|

|

|

|

|

|

|

|

| |

see Operating Set Point And Differential Adjustment on page 45. |

|

|

|

|

|

• The control system has detected the Blocked Exhaust Switch |

|

|

|

|

|

contacts are open. |

| Blocked Exhaust |

| ||

• The condensate drain is blocked filling the exhaust elbow with |

|

| |||

| Fault occurred 2 mins ago |

|

|

| |

water - clear the condensate drain - see Figure 9 on page 16. |

|

|

|

| |

The exhaust is blocked or |

|

|

| ||

• Loose or open wiring to the Blocked Exhaust Switch - see Figure 3 |

|

|

| ||

restricted. Ensure |

|

|

| ||

|

|

| |||

on page 8 for switch location. | condensate hose is draining. |

|

| ||

• Restricted/blocked vent piping - condensate trapped in low point. | Call a service professional: |

|

| ||

• Excessive equivalent pipe length, exceeded the maximum number |

|

| |||

Your Company Name Here |

|

| |||

of 90° elbows or wrong pipe size used in the vent piping system - |

|

| |||

(press [DOWN] for more....) |

|

| |||

|

| ||||

see Venting Requirements on page 22. |

|

| |||

CHANGE | BACK | ADVANCED |

| ||

• Excessive wind outdoors pressurizing the vent system piping. |

| ||||

|

|

|

|

| |

• Excessive negative air pressure in the installed space. |

|

|

|

|

|

58