Torque requirements

Nuts and bolts should only be adjusted using a torque wrench. This helps to prevent over tightening and damage to the threads. Different torque measurements are recommended when tightening different components. Use the following table to guide you in your torque application.

Component | Torque | |

|

|

|

Front axle nuts | 22 | – 27 Nm |

Rear axle nuts | 24 | – 29 Nm |

Handlebar clamp nut | 17 | – 19 Nm |

Head stem expander bolt | 17 | - 19 Nm |

Seat clamp nuts | 12 | – 17 Nm |

Seat post binder nut | 15 | – 19 Nm |

Brake cable fixing nut | 7 – 11 Nm | |

Brake calliper centre bolt nut 1 | 2 – 17 Nm | |

Cotterless crank nut | 27 | Nm |

|

|

|

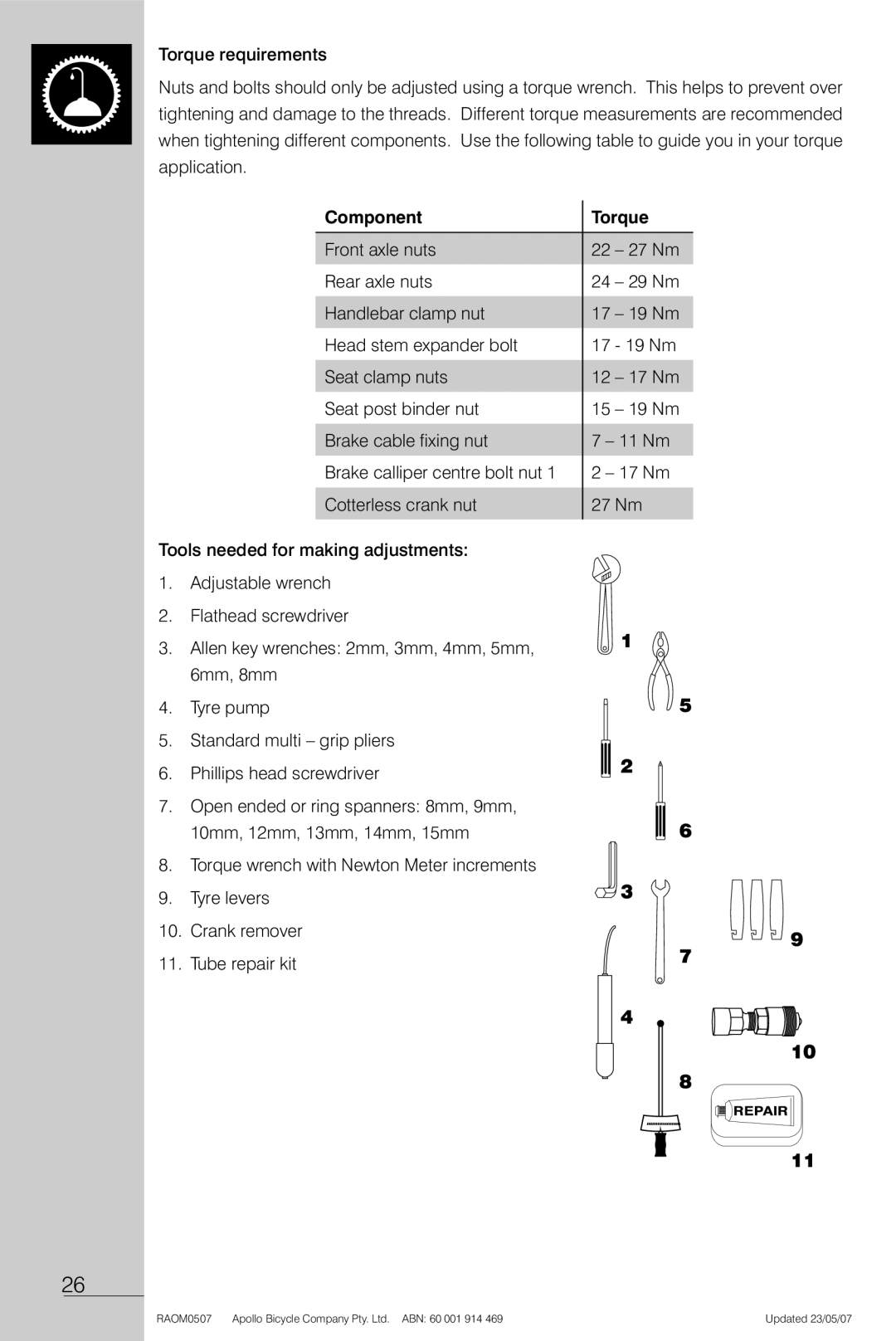

Tools needed for making adjustments:

1.Adjustable wrench

2.Flathead screwdriver

3. Allen key wrenches: 2mm, 3mm, 4mm, 5mm, 6mm, 8mm

4. Tyre pump

5. Standard multi – grip pliers

6. Phillips head screwdriver

7. Open ended or ring spanners: 8mm, 9mm, 10mm, 12mm, 13mm, 14mm, 15mm

8. Torque wrench with Newton Meter increments

9. Tyre levers

10. Crank remover

11. Tube repair kit

26

RAOM0507 | Apollo Bicycle Company Pty. Ltd. ABN: 60 001 914 469 | Updated 23/05/07 |