Brake Shoe Replacement

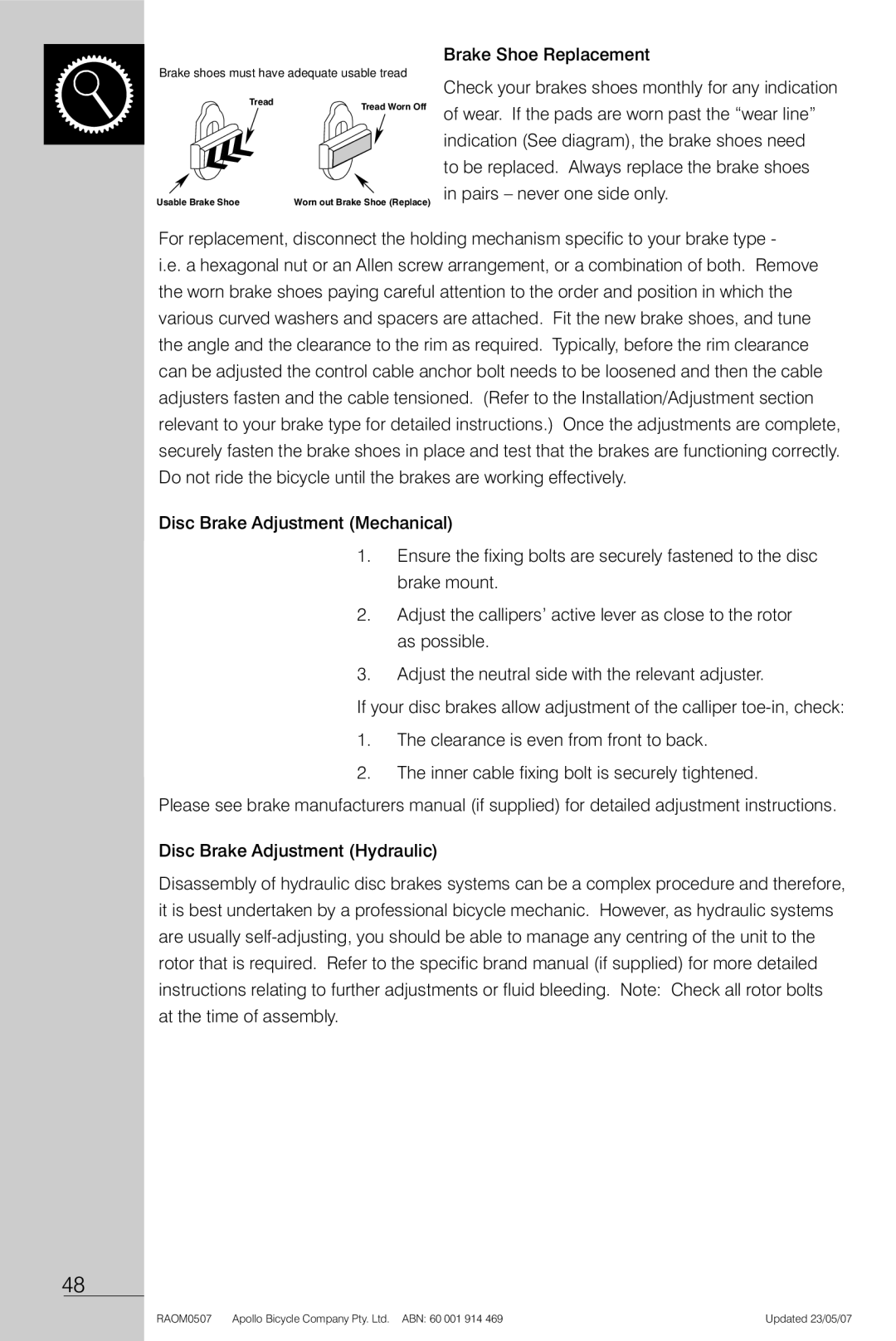

Brake shoes must have adequate usable tread

| Tread | Tread Worn Off |

|

| |

Usable Brake Shoe |

| Worn out Brake Shoe (Replace) |

Check your brakes shoes monthly for any indication of wear. If the pads are worn past the “wear line” indication (See diagram), the brake shoes need

to be replaced. Always replace the brake shoes in pairs – never one side only.

For replacement, disconnect the holding mechanism specific to your brake type -

i.e. a hexagonal nut or an Allen screw arrangement, or a combination of both. Remove the worn brake shoes paying careful attention to the order and position in which the various curved washers and spacers are attached. Fit the new brake shoes, and tune the angle and the clearance to the rim as required. Typically, before the rim clearance can be adjusted the control cable anchor bolt needs to be loosened and then the cable adjusters fasten and the cable tensioned. (Refer to the Installation/Adjustment section relevant to your brake type for detailed instructions.) Once the adjustments are complete, securely fasten the brake shoes in place and test that the brakes are functioning correctly. Do not ride the bicycle until the brakes are working effectively.

Disc Brake Adjustment (Mechanical)

1.Ensure the fixing bolts are securely fastened to the disc brake mount.

2.Adjust the callipers’ active lever as close to the rotor as possible.

3.Adjust the neutral side with the relevant adjuster.

If your disc brakes allow adjustment of the calliper

1.The clearance is even from front to back.

2.The inner cable fixing bolt is securely tightened.

Please see brake manufacturers manual (if supplied) for detailed adjustment instructions.

Disc Brake Adjustment (Hydraulic)

Disassembly of hydraulic disc brakes systems can be a complex procedure and therefore, it is best undertaken by a professional bicycle mechanic. However, as hydraulic systems are usually

48

RAOM0507 | Apollo Bicycle Company Pty. Ltd. ABN: 60 001 914 469 | Updated 23/05/07 |