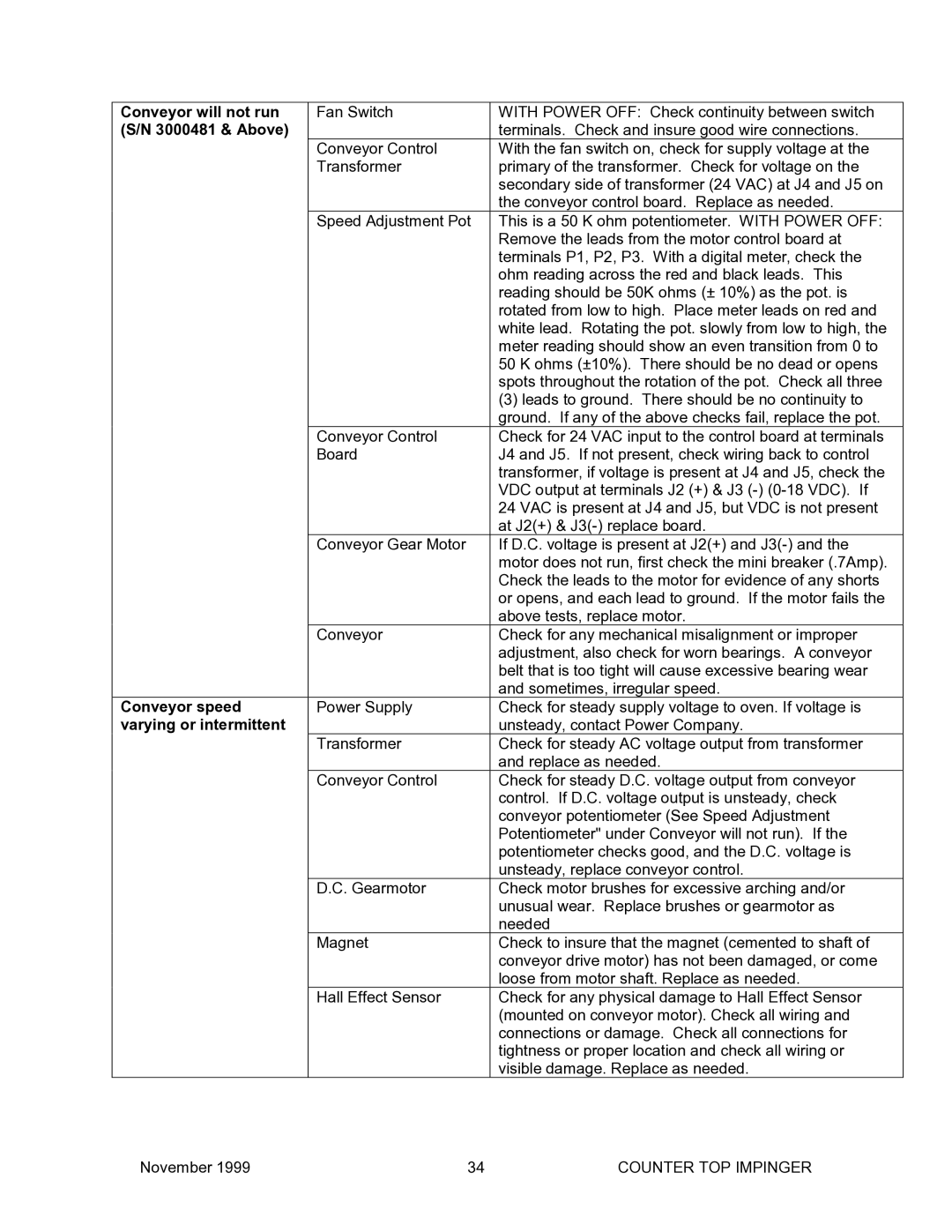

Conveyor will not run | Fan Switch | WITH POWER OFF: Check continuity between switch |

(S/N 3000481 & Above) |

| terminals. Check and insure good wire connections. |

| Conveyor Control | With the fan switch on, check for supply voltage at the |

| Transformer | primary of the transformer. Check for voltage on the |

|

| secondary side of transformer (24 VAC) at J4 and J5 on |

|

| the conveyor control board. Replace as needed. |

| Speed Adjustment Pot | This is a 50 K ohm potentiometer. WITH POWER OFF: |

|

| Remove the leads from the motor control board at |

|

| terminals P1, P2, P3. With a digital meter, check the |

|

| ohm reading across the red and black leads. This |

|

| reading should be 50K ohms (± 10%) as the pot. is |

|

| rotated from low to high. Place meter leads on red and |

|

| white lead. Rotating the pot. slowly from low to high, the |

|

| meter reading should show an even transition from 0 to |

|

| 50 K ohms (±10%). There should be no dead or opens |

|

| spots throughout the rotation of the pot. Check all three |

|

| (3) leads to ground. There should be no continuity to |

|

| ground. If any of the above checks fail, replace the pot. |

| Conveyor Control | Check for 24 VAC input to the control board at terminals |

| Board | J4 and J5. If not present, check wiring back to control |

|

| transformer, if voltage is present at J4 and J5, check the |

|

| VDC output at terminals J2 (+) & J3 |

|

| 24 VAC is present at J4 and J5, but VDC is not present |

|

| at J2(+) & |

| Conveyor Gear Motor | If D.C. voltage is present at J2(+) and |

|

| motor does not run, first check the mini breaker (.7Amp). |

|

| Check the leads to the motor for evidence of any shorts |

|

| or opens, and each lead to ground. If the motor fails the |

|

| above tests, replace motor. |

| Conveyor | Check for any mechanical misalignment or improper |

|

| adjustment, also check for worn bearings. A conveyor |

|

| belt that is too tight will cause excessive bearing wear |

|

| and sometimes, irregular speed. |

Conveyor speed | Power Supply | Check for steady supply voltage to oven. If voltage is |

varying or intermittent |

| unsteady, contact Power Company. |

| Transformer | Check for steady AC voltage output from transformer |

|

| and replace as needed. |

| Conveyor Control | Check for steady D.C. voltage output from conveyor |

|

| control. If D.C. voltage output is unsteady, check |

|

| conveyor potentiometer (See Speed Adjustment |

|

| Potentiometer" under Conveyor will not run). If the |

|

| potentiometer checks good, and the D.C. voltage is |

|

| unsteady, replace conveyor control. |

| D.C. Gearmotor | Check motor brushes for excessive arching and/or |

|

| unusual wear. Replace brushes or gearmotor as |

|

| needed |

| Magnet | Check to insure that the magnet (cemented to shaft of |

|

| conveyor drive motor) has not been damaged, or come |

|

| loose from motor shaft. Replace as needed. |

| Hall Effect Sensor | Check for any physical damage to Hall Effect Sensor |

|

| (mounted on conveyor motor). Check all wiring and |

|

| connections or damage. Check all connections for |

|

| tightness or proper location and check all wiring or |

|

| visible damage. Replace as needed. |

November 1999 | 34 | COUNTER TOP IMPINGER |