Appendix A

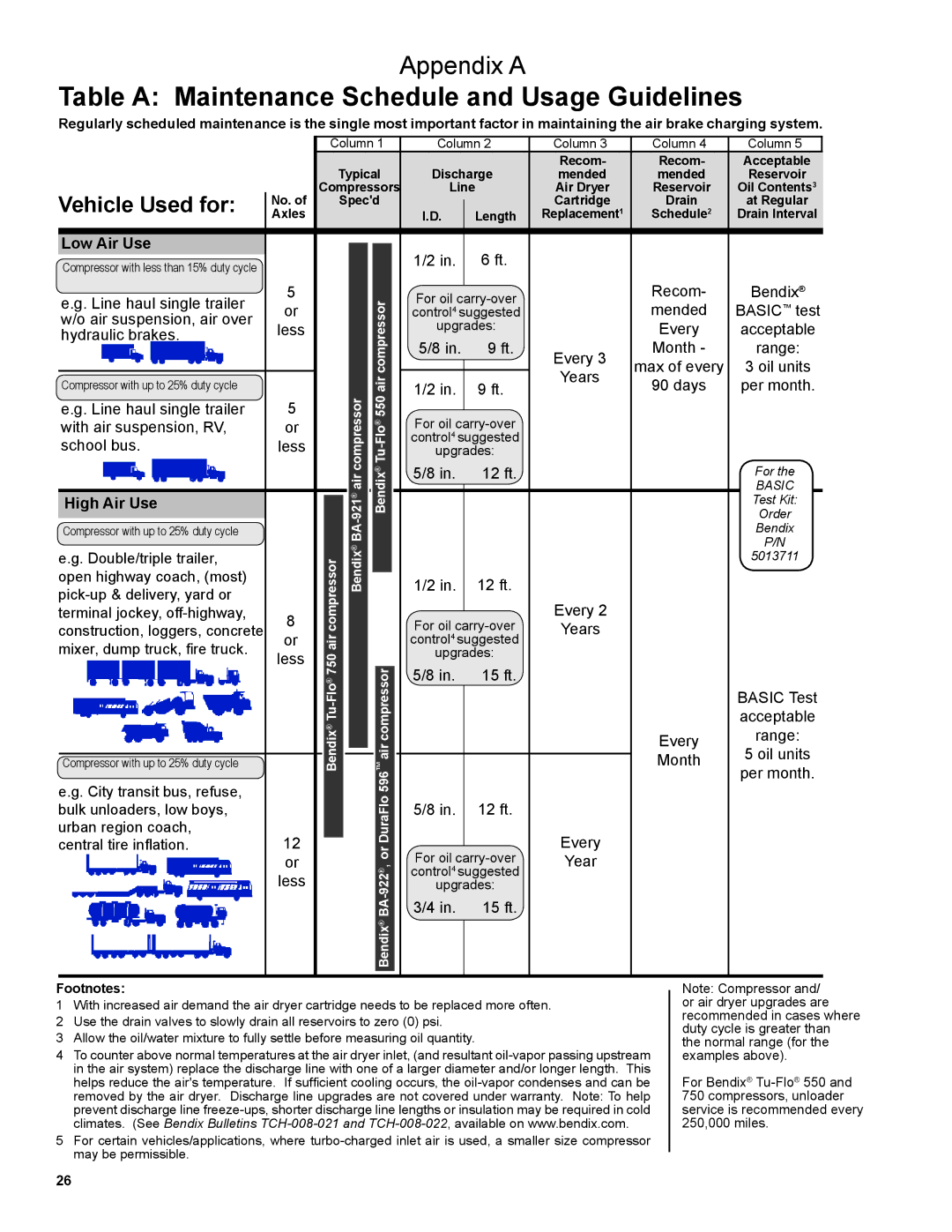

Table A: Maintenance Schedule and Usage Guidelines

Regularly scheduled maintenance is the single most important factor in maintaining the air brake charging system.

Vehicle Used for: | Axles | |

| No. of | |

|

| |

Low Air Use |

| |

Compressor with less than 15% duty cycle |

| |

e.g. Line haul single trailer | 5 | |

or | ||

w/o air suspension, air over | ||

less | ||

hydraulic brakes. | ||

Compressor with up to 25% duty cycle |

| |

e.g. Line haul single trailer | 5 | |

with air suspension, RV, | or | |

school bus. | less | |

|

| |

High Air Use |

| |

Compressor with up to 25% duty cycle |

| |

e.g. Double/triple trailer, |

| |

open highway coach, (most) |

| |

| ||

terminal jockey, | 8 | |

construction, loggers, concrete | ||

or | ||

mixer, dump truck, fire truck. | ||

less | ||

|

Compressor with up to 25% duty cycle |

|

e.g. City transit bus, refuse, |

|

bulk unloaders, low boys, |

|

urban region coach, | 12 |

central tire inflation. | |

| or |

| less |

Column 1 | Column 2 | Column 3 | Column 4 | Column 5 | |

Typical | Discharge | Recom- | Recom- | Acceptable | |

mended | mended | Reservoir | |||

Compressors |

| Line | Air Dryer | Reservoir | Oil Contents3 |

Spec'd |

|

| Cartridge | Drain | at Regular |

| I.D. | Length | Replacement1 | Schedule2 | Drain Interval |

|

|

|

|

|

|

|

|

|

|

|

| 1/2 in. | 6 ft. |

|

|

|

|

| compressor |

|

| For oil |

| Recom- | Bendix® | ||

|

|

|

| control4 suggested | Every 3 | mended | BASIC™ test | |||

|

|

|

| upgrades: | max of every | 3 oil units | ||||

|

|

|

|

|

|

| Every | acceptable | ||

|

|

|

|

|

| 5/8 in. | 9 ft. |

| Month - | range: |

|

| air |

|

|

|

| Years | 90 days | per month. | |

| compressor |

|

| 1/2 in. | 9 ft. | |||||

|

|

|

| |||||||

| Tu‑Flo®® 550 |

|

| For oil |

|

|

| |||

|

|

|

|

|

| control4 suggested |

|

|

| |

|

|

|

|

|

| upgrades: |

|

|

| |

| air921® | Bendix |

|

| 5/8 in. | 12 ft. |

|

| For the | |

|

|

|

|

|

|

| BASIC | |||

|

|

|

|

|

|

|

|

|

| Test Kit: |

- |

|

|

|

|

|

|

|

| Order | |

| ® BA |

|

|

|

|

|

|

|

| Bendix |

|

|

|

|

|

|

|

|

| P/N | |

compressor Bendix |

|

|

|

| For oil | Years |

| 5013711 | ||

|

|

|

|

|

| |||||

|

|

|

|

|

| 1/2 in. | 12 ft. |

|

|

|

|

|

|

|

|

|

|

| Every 2 |

|

|

air |

|

|

|

| control4 suggested |

|

|

| ||

|

|

|

| upgrades: |

|

|

| |||

Tu‑Flo®® 750 |

|

|

|

|

|

|

| |||

| compressor |

|

| 5/8 in. | 15 ft. |

|

| range: | ||

|

|

|

|

|

|

|

|

|

| BASIC Test |

Bendix | 596 |

|

|

|

|

|

| acceptable | ||

|

|

|

|

| Every |

| ||||

|

|

| air |

|

|

|

|

| 5 oil units | |

|

|

|

|

|

|

|

| Month | ||

|

|

|

|

|

|

|

| |||

|

| ™ |

|

|

|

|

| per month. | ||

|

|

| DuraFlo |

|

|

|

|

|

| |

|

|

|

|

| 5/8 in. | 12 ft. |

|

|

| |

|

|

|

|

|

|

|

|

| ||

|

|

| or |

|

| For oil | Every |

|

| |

|

|

|

|

| Year |

|

| |||

|

| ®, |

|

|

|

| ||||

|

|

|

| control4 suggested |

|

|

| |||

|

| 922 |

|

| upgrades: |

|

|

| ||

|

|

| BA- |

|

| 3/4 in. | 15 ft. |

|

|

|

|

|

| Bendix® |

|

|

|

|

|

|

|

Footnotes:

1With increased air demand the air dryer cartridge needs to be replaced more often.

2Use the drain valves to slowly drain all reservoirs to zero (0) psi.

3Allow the oil/water mixture to fully settle before measuring oil quantity.

4To counter above normal temperatures at the air dryer inlet, (and resultant

5For certain vehicles/applications, where

Note: Compressor and/ or air dryer upgrades are recommended in cases where duty cycle is greater than the normal range (for the examples above).

For Bendix®

26