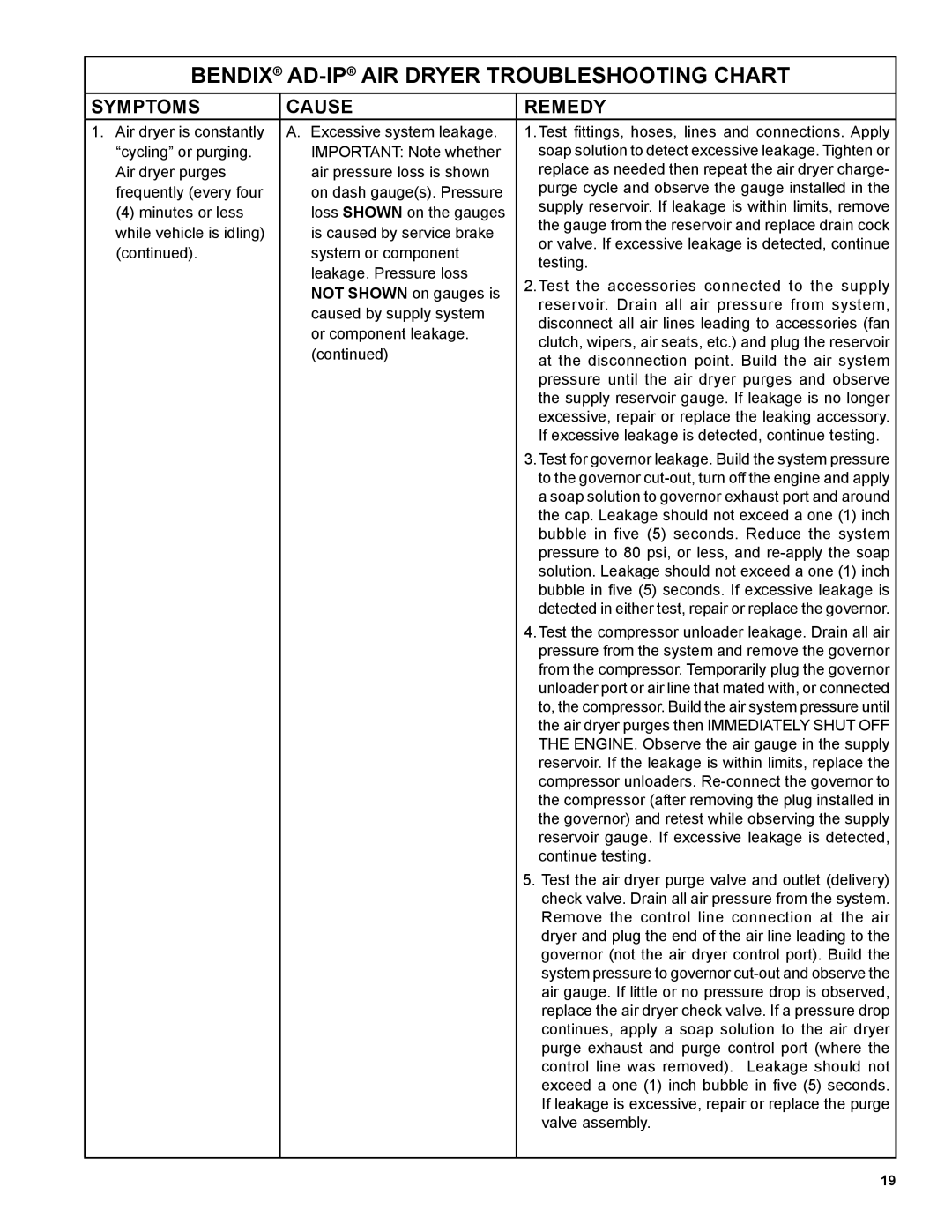

BENDIX® AD-IP® AIR DRYER TROUBLESHOOTING CHART

SYMPTOMS | CAUSE | REMEDY | |

1. Air dryer is constantly | A. Excessive system leakage. | 1.Test fittings, hoses, lines and connections. Apply | |

“cycling” or purging. | IMPORTANT: Note whether | soap solution to detect excessive leakage. Tighten or | |

Air dryer purges | air pressure loss is shown | replace as needed then repeat the air dryer charge- | |

frequently (every four | on dash gauge(s). Pressure | purge cycle and observe the gauge installed in the | |

(4) minutes or less | loss SHOWN on the gauges | supply reservoir. If leakage is within limits, remove | |

the gauge from the reservoir and replace drain cock | |||

while vehicle is idling) | is caused by service brake | ||

or valve. If excessive leakage is detected, continue | |||

(continued). | system or component | ||

testing. | |||

| leakage. Pressure loss | ||

| 2.Test the accessories connected to the supply | ||

| NOT SHOWN on gauges is | ||

| reservoir. Drain all air pressure from system, | ||

| caused by supply system | ||

| disconnect all air lines leading to accessories (fan | ||

| or component leakage. | ||

| clutch, wipers, air seats, etc.) and plug the reservoir | ||

| (continued) | ||

| at the disconnection point. Build the air system | ||

|

| ||

|

| pressure until the air dryer purges and observe | |

|

| the supply reservoir gauge. If leakage is no longer | |

|

| excessive, repair or replace the leaking accessory. | |

|

| If excessive leakage is detected, continue testing. | |

|

| 3.Test for governor leakage. Build the system pressure | |

|

| to the governor | |

|

| a soap solution to governor exhaust port and around | |

|

| the cap. Leakage should not exceed a one (1) inch | |

|

| bubble in five (5) seconds. Reduce the system | |

|

| pressure to 80 psi, or less, and | |

|

| solution. Leakage should not exceed a one (1) inch | |

|

| bubble in five (5) seconds. If excessive leakage is | |

|

| detected in either test, repair or replace the governor. | |

|

| 4.Test the compressor unloader leakage. Drain all air | |

|

| pressure from the system and remove the governor | |

|

| from the compressor. Temporarily plug the governor | |

|

| unloader port or air line that mated with, or connected | |

|

| to, the compressor. Build the air system pressure until | |

|

| the air dryer purges then IMMEDIATELY SHUT OFF | |

|

| THE ENGINE. Observe the air gauge in the supply | |

|

| reservoir. If the leakage is within limits, replace the | |

|

| compressor unloaders. | |

|

| the compressor (after removing the plug installed in | |

|

| the governor) and retest while observing the supply | |

|

| reservoir gauge. If excessive leakage is detected, | |

|

| continue testing. | |

|

| 5. Test the air dryer purge valve and outlet (delivery) | |

|

| check valve. Drain all air pressure from the system. | |

|

| Remove the control line connection at the air | |

|

| dryer and plug the end of the air line leading to the | |

|

| governor (not the air dryer control port). Build the | |

|

| system pressure to governor | |

|

| air gauge. If little or no pressure drop is observed, | |

|

| replace the air dryer check valve. If a pressure drop | |

|

| continues, apply a soap solution to the air dryer | |

|

| purge exhaust and purge control port (where the | |

|

| control line was removed). Leakage should not | |

|

| exceed a one (1) inch bubble in five (5) seconds. | |

|

| If leakage is excessive, repair or replace the purge | |

|

| valve assembly. | |

|

|

|

19