OIL

SEPARATOR

![]() DESICCANT

DESICCANT

BED

PURGE

ORIFICE

PURGE

VOLUME

CONTROL

PORT

PURGE

CONTROL

LINE

SUPPLY

PORT

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| DELIVERY |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

GOVERNOR |

|

|

|

|

|

|

|

|

|

|

|

|

|

| CHECK VALVE |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| DISCHARGE | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| PORT | |

|

| ENGINE |

|

|

|

|

|

|

|

|

| PURGE | |||

|

|

|

| TURBO |

|

|

| EXHAUST |

| ||||||

COMPRESSOR | TURBO |

| VALVE | ||||||||||||

|

|

|

| ||||||||||||

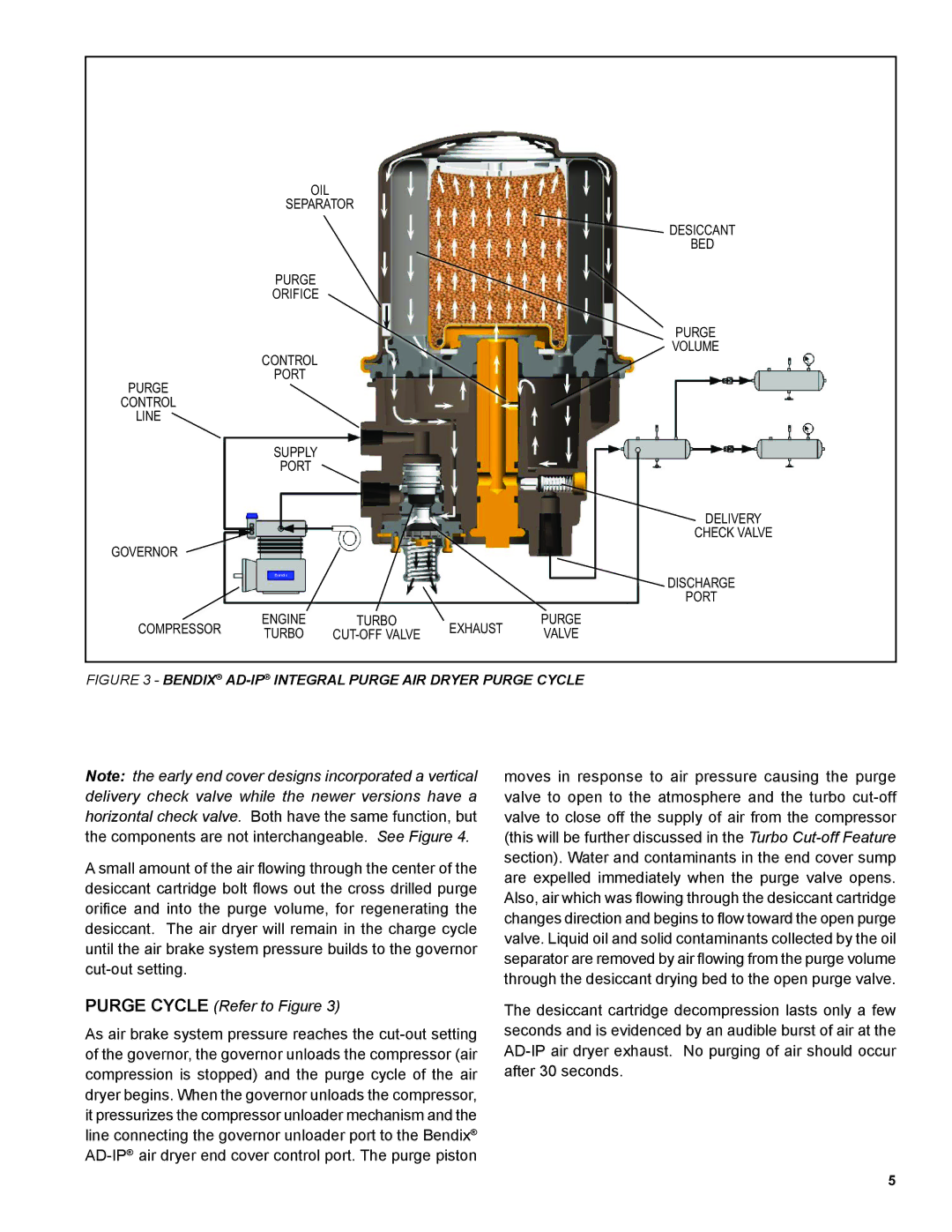

FIGURE 3 - BENDIX® AD-IP® INTEGRAL PURGE AIR DRYER PURGE CYCLE

Note: the early end cover designs incorporated a vertical delivery check valve while the newer versions have a horizontal check valve. Both have the same function, but the components are not interchangeable. See Figure 4.

A small amount of the air flowing through the center of the desiccant cartridge bolt flows out the cross drilled purge orifice and into the purge volume, for regenerating the desiccant. The air dryer will remain in the charge cycle until the air brake system pressure builds to the governor

PURGE CYCLE (Refer to Figure 3)

As air brake system pressure reaches the

moves in response to air pressure causing the purge valve to open to the atmosphere and the turbo

The desiccant cartridge decompression lasts only a few seconds and is evidenced by an audible burst of air at the

5