At the onset of the purge cycle, the downward travel of the purge piston is stopped when the turbo cut-off valve (tapered portion of purge piston) contacts its mating metal seat in the purge valve housing. With the turbo cut-off valve seated (closed position), air in the compressor discharge line and Bendix® AD-IP®air dryer inlet port cannot enter the air dryer. In this manner the turbo cut-off effectively maintains turbocharger boost pressure to the engine.

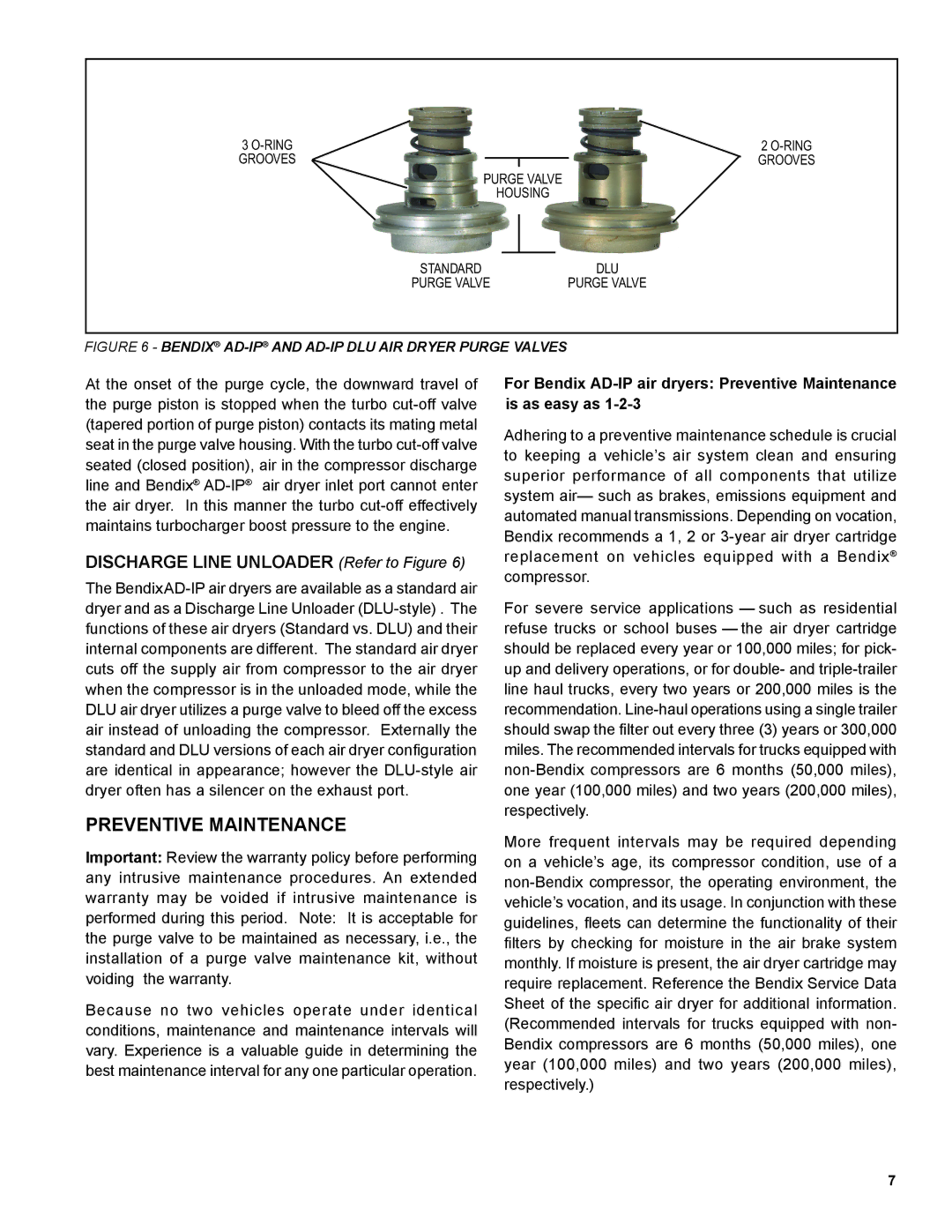

DISCHARGE LINE UNLOADER (Refer to Figure 6)

The BendixAD-IP air dryers are available as a standard air dryer and as a Discharge Line Unloader (DLU-style) . The functions of these air dryers (Standard vs. DLU) and their internal components are different. The standard air dryer cuts off the supply air from compressor to the air dryer when the compressor is in the unloaded mode, while the DLU air dryer utilizes a purge valve to bleed off the excess air instead of unloading the compressor. Externally the standard and DLU versions of each air dryer configuration are identical in appearance; however the DLU-style air dryer often has a silencer on the exhaust port.

PREVENTIVE MAINTENANCE

Important: Review the warranty policy before performing any intrusive maintenance procedures. An extended warranty may be voided if intrusive maintenance is performed during this period. Note: It is acceptable for the purge valve to be maintained as necessary, i.e., the installation of a purge valve maintenance kit, without voiding the warranty.

Because no two vehicles operate under identical conditions, maintenance and maintenance intervals will vary. Experience is a valuable guide in determining the best maintenance interval for any one particular operation.

For Bendix AD-IP air dryers: Preventive Maintenance is as easy as 1-2-3

Adhering to a preventive maintenance schedule is crucial to keeping a vehicle’s air system clean and ensuring superior performance of all components that utilize system air— such as brakes, emissions equipment and automated manual transmissions. Depending on vocation, Bendix recommends a 1, 2 or 3-year air dryer cartridge replacement on vehicles equipped with a Bendix® compressor.

For severe service applications — such as residential refuse trucks or school buses — the air dryer cartridge should be replaced every year or 100,000 miles; for pick- up and delivery operations, or for double- and triple-trailer line haul trucks, every two years or 200,000 miles is the recommendation. Line-haul operations using a single trailer should swap the filter out every three (3) years or 300,000 miles. The recommended intervals for trucks equipped with non-Bendix compressors are 6 months (50,000 miles), one year (100,000 miles) and two years (200,000 miles), respectively.

More frequent intervals may be required depending on a vehicle’s age, its compressor condition, use of a non-Bendix compressor, the operating environment, the vehicle’s vocation, and its usage. In conjunction with these guidelines, fleets can determine the functionality of their filters by checking for moisture in the air brake system monthly. If moisture is present, the air dryer cartridge may require replacement. Reference the Bendix Service Data Sheet of the specific air dryer for additional information. (Recommended intervals for trucks equipped with non- Bendix compressors are 6 months (50,000 miles), one year (100,000 miles) and two years (200,000 miles), respectively.)