INSTALLATION

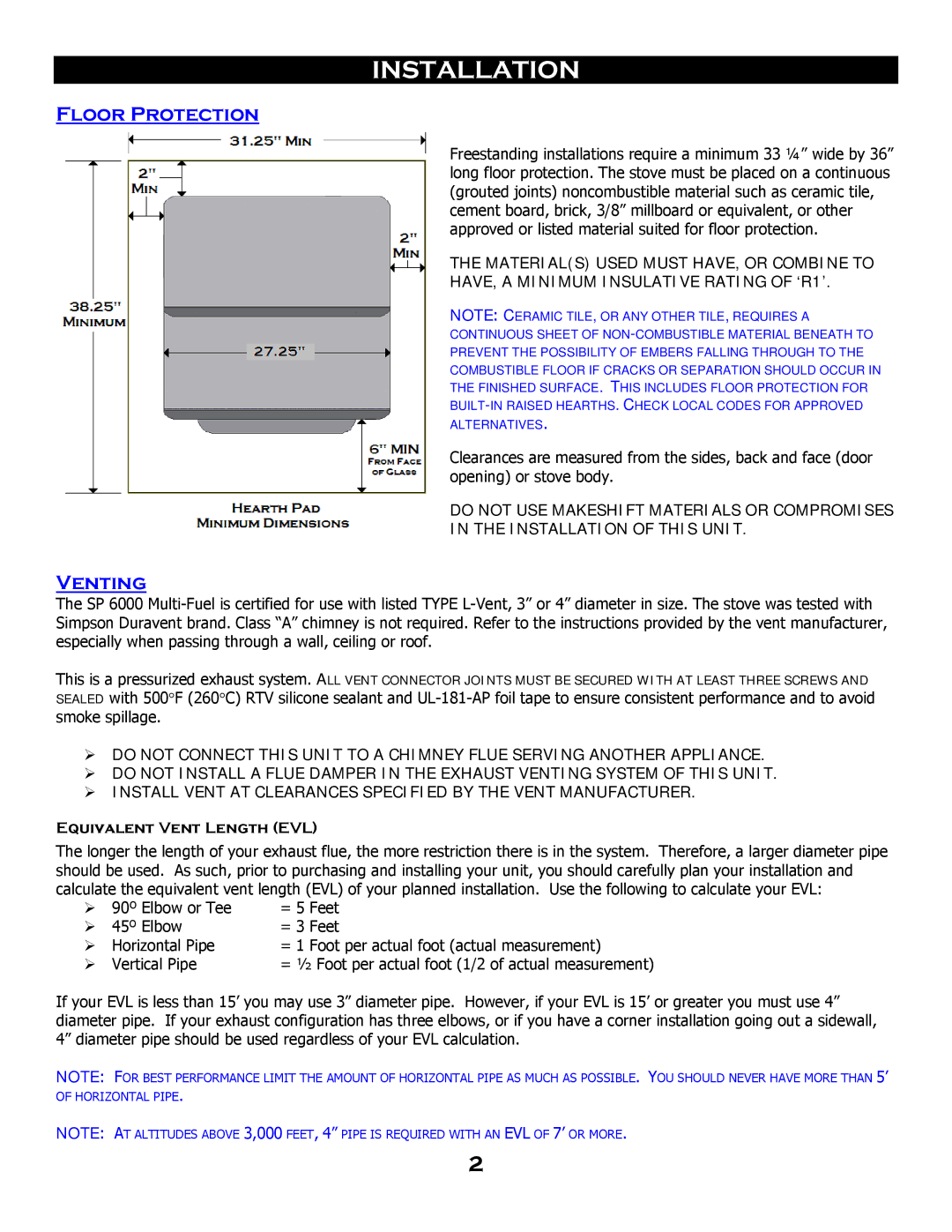

Floor Protection

Freestanding installations require a minimum 33 ¼” wide by 36” long floor protection. The stove must be placed on a continuous (grouted joints) noncombustible material such as ceramic tile, cement board, brick, 3/8” millboard or equivalent, or other approved or listed material suited for floor protection.

THE MATERIAL(S) USED MUST HAVE, OR COMBINE TO

HAVE, A MINIMUM INSULATIVE RATING OF ‘R1’.

NOTE: CERAMIC TILE, OR ANY OTHER TILE, REQUIRES A

CONTINUOUS SHEET OF

PREVENT THE POSSIBILITY OF EMBERS FALLING THROUGH TO THE

COMBUSTIBLE FLOOR IF CRACKS OR SEPARATION SHOULD OCCUR IN

THE FINISHED SURFACE. THIS INCLUDES FLOOR PROTECTION FOR

ALTERNATIVES.

Clearances are measured from the sides, back and face (door opening) or stove body.

DO NOT USE MAKESHIFT MATERIALS OR COMPROMISES

IN THE INSTALLATION OF THIS UNIT.

Venting

The SP 6000

This is a pressurized exhaust system. ALL VENT CONNECTOR JOINTS MUST BE SECURED WITH AT LEAST THREE SCREWS AND

SEALED with 500°F (260°C) RTV silicone sealant and

DO NOT CONNECT THIS UNIT TO A CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

DO NOT INSTALL A FLUE DAMPER IN THE EXHAUST VENTING SYSTEM OF THIS UNIT.

INSTALL VENT AT CLEARANCES SPECIFIED BY THE VENT MANUFACTURER.

Equivalent Vent Length (EVL)

The longer the length of your exhaust flue, the more restriction there is in the system. Therefore, a larger diameter pipe should be used. As such, prior to purchasing and installing your unit, you should carefully plan your installation and calculate the equivalent vent length (EVL) of your planned installation. Use the following to calculate your EVL:

90º Elbow or Tee | = 5 | Feet | |

| 45º Elbow | = 3 | Feet |

| Horizontal Pipe | = 1 | Foot per actual foot (actual measurement) |

| Vertical Pipe | = ½ Foot per actual foot (1/2 of actual measurement) | |

If your EVL is less than 15’ you may use 3” diameter pipe. However, if your EVL is 15’ or greater you must use 4” diameter pipe. If your exhaust configuration has three elbows, or if you have a corner installation going out a sidewall, 4” diameter pipe should be used regardless of your EVL calculation.

NOTE: FOR BEST PERFORMANCE LIMIT THE AMOUNT OF HORIZONTAL PIPE AS MUCH AS POSSIBLE. YOU SHOULD NEVER HAVE MORE THAN 5’ OF HORIZONTAL PIPE.

NOTE: AT ALTITUDES ABOVE 3,000 FEET, 4” PIPE IS REQUIRED WITH AN EVL OF 7’ OR MORE.

2