551J

MAXIMUM ALLOWABLE

DIFFERENCE IN. (MM)

0.5” (13) | 1.0” (25) | 1.0” (25) |

C06110

Fig. 4 - Unit Leveling Tolerances

Step 5 — Field Fabricate Ductwork

Cabinet

j0.45 in. wg (112 Pa) without economizer.

For vertical ducted applications, secure all ducts to roof curb and building structure on vertical ducted units. Do not connect ductwork to unit.

Insulate and weatherproof all external ductwork, joints, and roof openings with counter flashing and mastic in accordance with applicable codes.

Ducts passing through unconditioned spaces must be insulated and covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return should be ducted through the roof deck to comply with applicable fire codes.

For units with accessory electric heaters: Horizontal applications require a minimum clearance to combustible surfaces of

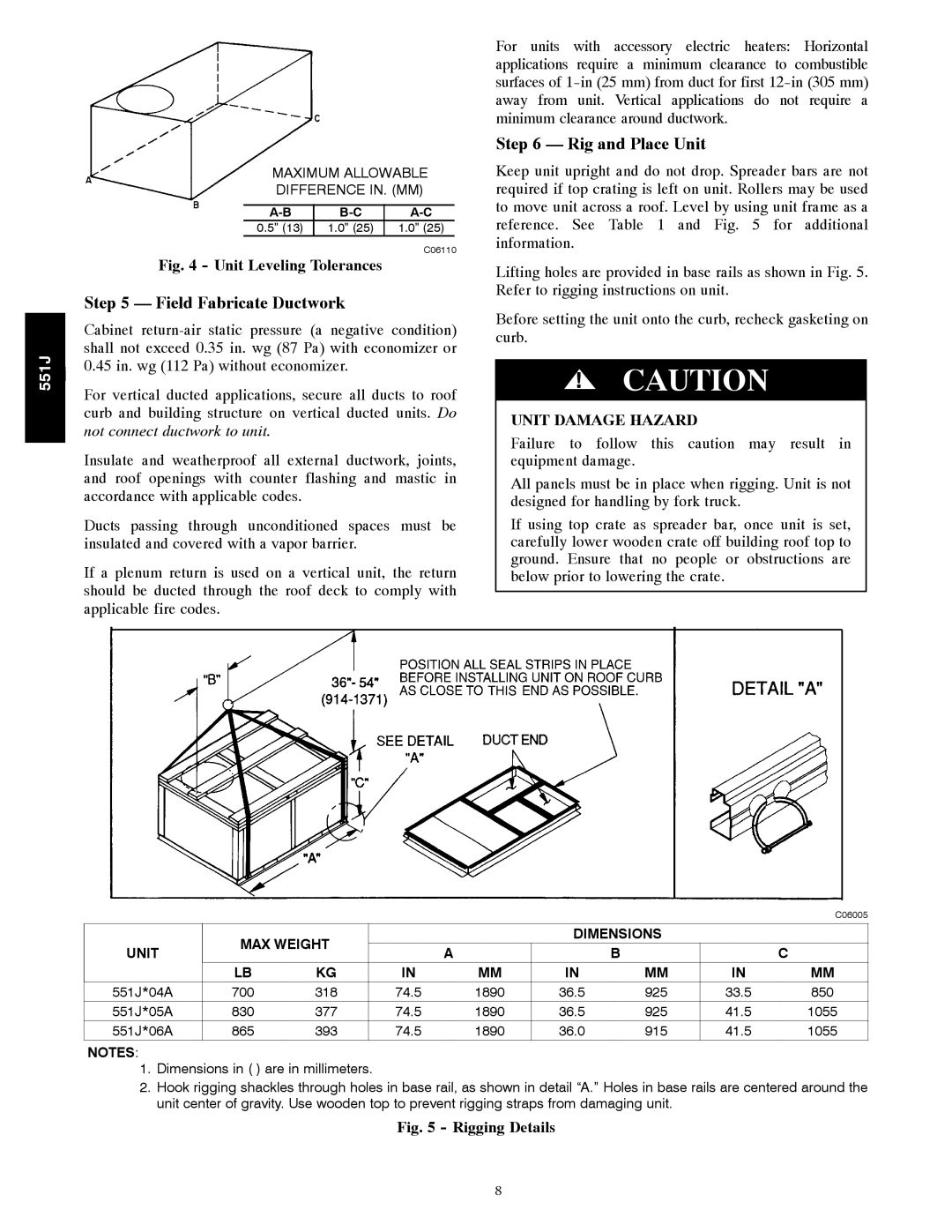

Step 6 — Rig and Place Unit

Keep unit upright and do not drop. Spreader bars are not required if top crating is left on unit. Rollers may be used to move unit across a roof. Level by using unit frame as a reference. See Table 1 and Fig. 5 for additional information.

Lifting holes are provided in base rails as shown in Fig. 5. Refer to rigging instructions on unit.

Before setting the unit onto the curb, recheck gasketing on curb.

!CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage.

All panels must be in place when rigging. Unit is not designed for handling by fork truck.

If using top crate as spreader bar, once unit is set, carefully lower wooden crate off building roof top to ground. Ensure that no people or obstructions are below prior to lowering the crate.

C06005

| MAX WEIGHT |

|

| DIMENSIONS |

|

| ||

UNIT |

| A |

| B |

| C | ||

|

|

|

|

| ||||

| LB | KG | IN | MM | IN | MM | IN | MM |

551J*04A | 700 | 318 | 74.5 | 1890 | 36.5 | 925 | 33.5 | 850 |

551J*05A | 830 | 377 | 74.5 | 1890 | 36.5 | 925 | 41.5 | 1055 |

551J*06A | 865 | 393 | 74.5 | 1890 | 36.0 | 915 | 41.5 | 1055 |

NOTES:

1.Dimensions in ( ) are in millimeters.

2.Hook rigging shackles through holes in base rail, as shown in detail “A.” Holes in base rails are centered around the unit center of gravity. Use wooden top to prevent rigging straps from damaging unit.

Fig. 5 - Rigging Details

8