Positioning on Curb —

Position unit on roof curb so that the following clearances are maintained: 1/4 in. (6.4 mm) clearance between the roof curb and the base rail inside the front and rear, 0.0 in. clearance between the roof curb and the base rail inside on the duct end of the unit. This will result in the distance between the roof curb and the base rail inside on the condenser end of the unit being approximately equal to Fig. 3, section

Although unit is weatherproof, guard against water from higher level runoff and overhangs.

!CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage.

All panels must be in place when rigging. Unit is not designed for handling by fork truck.

After unit is in position, remove rigging skids and shipping materials.

Step 7 — Convert to Horizontal and Connect Ductwork (when required)

Unit is shipped in the vertical duct configuration. Unit without

C06108

Fig. 6 - Horizontal Conversion Panels

Do not cover or obscure visibility to the unit’s informative data plate when insulating horizontal ductwork.

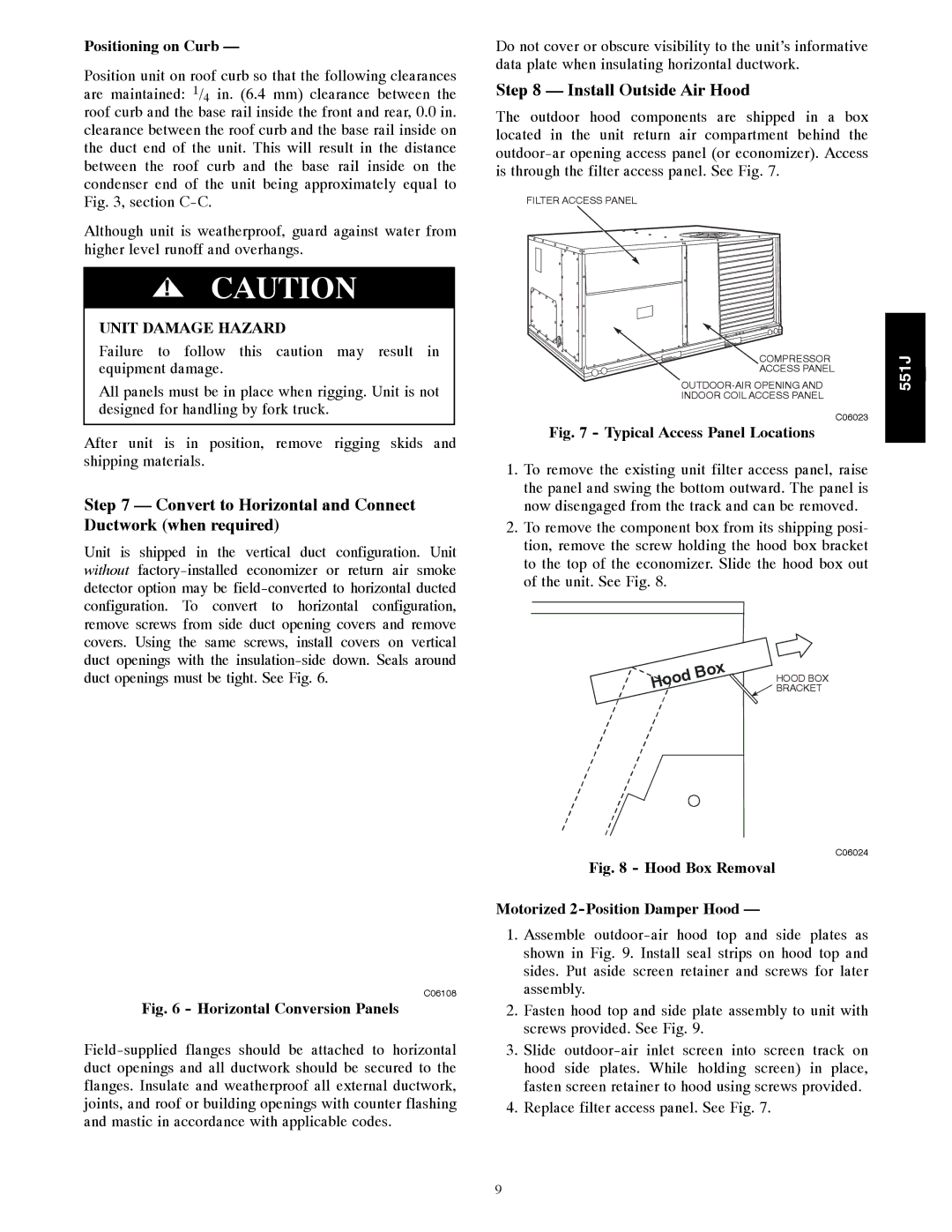

Step 8 — Install Outside Air Hood

The outdoor hood components are shipped in a box located in the unit return air compartment behind the

FILTER ACCESS PANEL

COMPRESSOR | 551J | j |

ACCESS PANEL |

|

|

INDOOR COIL ACCESS PANEL |

|

|

| C06023 |

|

Fig. 7 - Typical Access Panel Locations

1.To remove the existing unit filter access panel, raise the panel and swing the bottom outward. The panel is now disengaged from the track and can be removed.

2.To remove the component box from its shipping posi- tion, remove the screw holding the hood box bracket to the top of the economizer. Slide the hood box out of the unit. See Fig. 8.

|

|

| x |

|

|

| o |

| |

o | B |

| HOOD BOX | |

H | od |

|

| |

|

|

| BRACKET | |

|

|

|

| |

C06024

Fig. 8 - Hood Box Removal

Motorized 2-Position Damper Hood —

1.Assemble

2.Fasten hood top and side plate assembly to unit with screws provided. See Fig. 9.

3.Slide

4.Replace filter access panel. See Fig. 7.

9