Noisy Compressor

Noise may be caused by a variety of internal and external factors. Careful attention to the “type” of noise may help identify the source. The following are some examples of abnormal conditions that may create objectionable noise:

1.A gurgling sound may indicate a liquid refrigerant floodback during operation. This could be confirmed if there is no compressor superheat. A compressor superheat of “0” degrees would indicate liquid refrigerant returning to the compressor. Most common reasons for floodback are: loss of evaporator blower, dirty coils, and improper airflow.

2.A rattling noise may indicate loose hardware. Inspect all unit hardware including the compressor grommets.

3.A straining (hard start) or vibration occurring at start up but clears quickly after could indicate an off cycle refrigerant migration issue. Refrigerant migration can occur when a compressor is off and refrigerant vapor transfers from other areas of the system, settles into the compressor as it is attracted to the oil, and then condenses into the oil. Upon start up, the compressor draws suction from within itself first and lowers the boiling point of the refrigerant that is entrained in the oil. This can cause the liquid refrigerant and oil to boil into the compression area or liquid refrigerant to wipe off oil films that are critical for proper lubrication. Migration is worsened by greater temperature differentials and/or extra refrigerant in the system. Prevention of migration can be reduced by various options but some of the more common remedies is to verify proper charge and add a crankcase heater where this situation is suspected.

4.Operational vibration could indicate a charge issue. Verify charge and ensure proper piping and structural penetration insulation. Tubing that is too rigid to building rafters without proper insulation could transfer noise throughout the structure. On some occasions a sound dampener or mass weight (RCD part no. 328209-751) placed on the vibrating tubing has been known to reduce this noise. Utilizing compressor split post grommets (see Fig. 12) may also reduce this vibration if piping cannot be remedied.

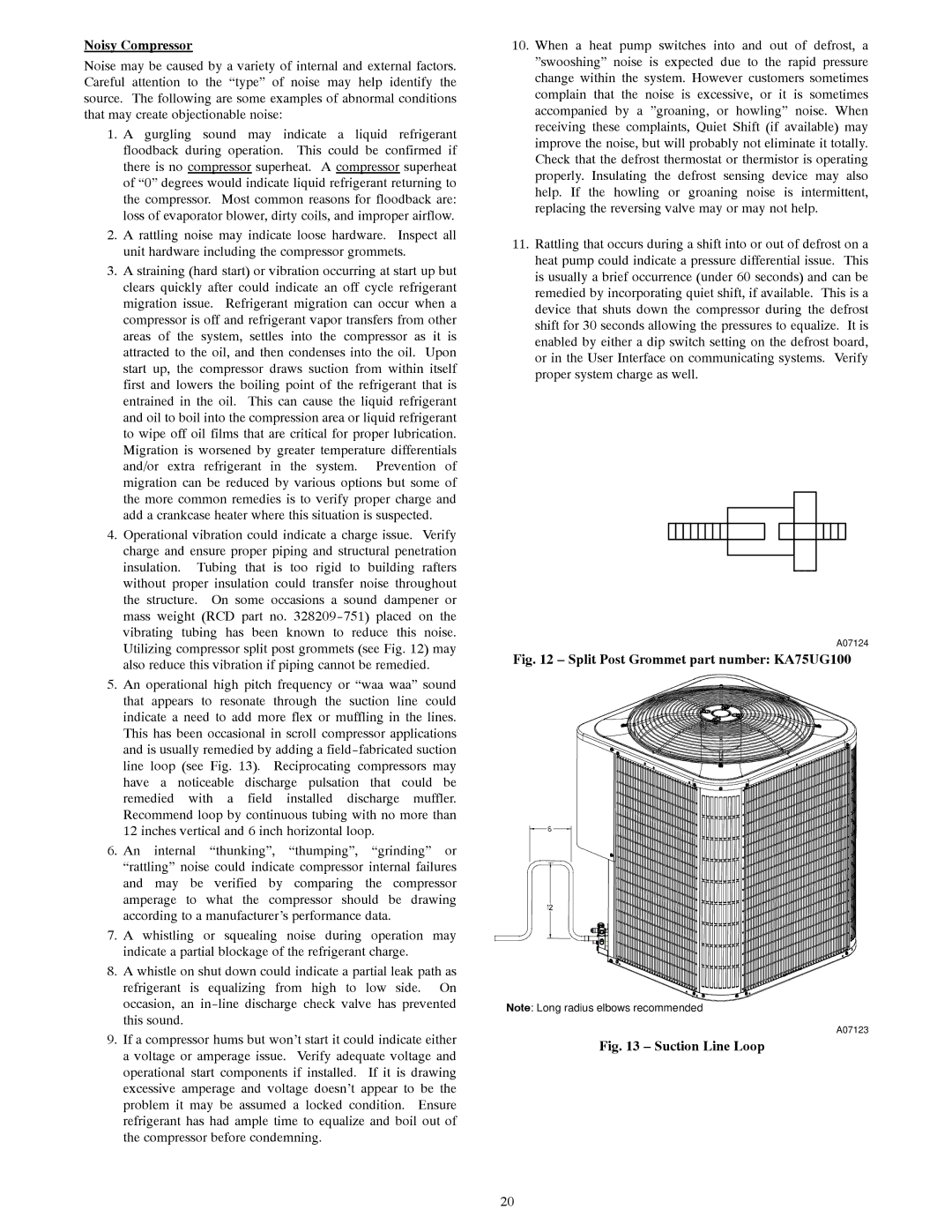

5.An operational high pitch frequency or “waa waa” sound that appears to resonate through the suction line could indicate a need to add more flex or muffling in the lines. This has been occasional in scroll compressor applications and is usually remedied by adding a field-fabricated suction line loop (see Fig. 13). Reciprocating compressors may have a noticeable discharge pulsation that could be remedied with a field installed discharge muffler. Recommend loop by continuous tubing with no more than 12 inches vertical and 6 inch horizontal loop.

6.An internal “thunking”, “thumping”, “grinding” or “rattling” noise could indicate compressor internal failures and may be verified by comparing the compressor amperage to what the compressor should be drawing according to a manufacturer’s performance data.

7.A whistling or squealing noise during operation may indicate a partial blockage of the refrigerant charge.

8.A whistle on shut down could indicate a partial leak path as refrigerant is equalizing from high to low side. On occasion, an in-line discharge check valve has prevented this sound.

9.If a compressor hums but won’t start it could indicate either a voltage or amperage issue. Verify adequate voltage and operational start components if installed. If it is drawing excessive amperage and voltage doesn’t appear to be the problem it may be assumed a locked condition. Ensure refrigerant has had ample time to equalize and boil out of the compressor before condemning.

10.When a heat pump switches into and out of defrost, a ”swooshing” noise is expected due to the rapid pressure change within the system. However customers sometimes complain that the noise is excessive, or it is sometimes accompanied by a ”groaning, or howling” noise. When receiving these complaints, Quiet Shift (if available) may improve the noise, but will probably not eliminate it totally. Check that the defrost thermostat or thermistor is operating properly. Insulating the defrost sensing device may also help. If the howling or groaning noise is intermittent, replacing the reversing valve may or may not help.

11.Rattling that occurs during a shift into or out of defrost on a heat pump could indicate a pressure differential issue. This is usually a brief occurrence (under 60 seconds) and can be remedied by incorporating quiet shift, if available. This is a device that shuts down the compressor during the defrost shift for 30 seconds allowing the pressures to equalize. It is enabled by either a dip switch setting on the defrost board, or in the User Interface on communicating systems. Verify proper system charge as well.

A07124

Fig. 12 – Split Post Grommet part number: KA75UG100

Note: Long radius elbows recommended

A07123

Fig. 13 – Suction Line Loop