Fan Motor

Fan motor rotates the fan blade that either draws or blows air through outdoor coil to exchange heat between refrigerant and air. Motors are totally enclosed to increase reliability. This also eliminates need for rain shield.

!WARNING

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury or death.

Turn off all power to unit before servicing or replacing fan motor. Be sure unit main power switch is turned off.

The bearings are permanently lubricated; therefore, no oil ports are provided.

For suspected electrical failures, check for loose or faulty electrical connections, or defective fan-motor capacitor. Fan motor is equipped with thermal overload device in motor windings which may open under adverse operating conditions. Allow time for motor to cool so device can reset. Further checking of motor can be done with an ohmmeter. Set scale on R X 1 position; check for continuity between three leads. Replace motors that show an open circuit in any of the windings. Place 1 lead of ohmmeter on each motor lead. At same time, place other ohmmeter lead on motor case (ground). Replace any motor that shows resistance to ground, signs of arcing, burning, or overheating.

Located above the compressor is a single-speed fan motor and fan. The 180ANA/288ANA air conditioner and heat pump models use the ECM variable speed fan motor.

The outdoor Integral Control Motor (ECM), is a variable-speed motor which operates from 450 to 850 rpm. The motor is a dc permanent magnet-type motor with the electronic controls integrated into its rear cover. The control package includes a small diode bridge, capacitors, and power switching devices. It converts ac to dc power and switches the dc power to the motor windings on and off at various rates to control the motor speed. The speed at which the motor windings are thus commutated is determined by a pulse width modulated (PWM) signal which is received from the control board on the motor control lines.

The PWM signal is created by turning a DC signal on and off once within a given period of time. The signal on time relative to the signal total period defines the percent of the PWM. For example, if the period is 5 sec and the control power is turned on for 1 sec then off, the signal will remain off for 4 sec before turning on again to start the next cycle. The PWM is called a 20 percent duty cycle signal. If the on time is increased to 4 sec of the 5 sec period, the PWM is called an 80 percent duty cycle. The ECM reads the PWM signal and increases the motor speed linearly from minimum speed to maximum speed with the percent duty cycle value of the supplied PWM signal.

Outdoor Fan Motor Operation

There are two different types of motors used in the Evolution 2-stage outdoor units. The 286A models use a PSC type fan motor, and the speed does not change between high and low speed operation.

On 288ANA models, an ECM fan motor is used to achieve higher efficiency ratings of the system. The outdoor unit control energizes outdoor fan anytime compressor is operating, except for defrost or low-ambient cooling. The outdoor fan remains energized if a pressure switch or compressor overload should open. The outdoor fan motor will continue to operate for one minute after the compressor shuts off when the outdoor ambient is greater than or equal to 100°F/37.7°C. This reduces pressure differential for easier starting on next cycle. On 286A/187ANA models, the outdoor fan remains energized during the 1-minute compressor staging time delay.

On 286ANA/187ANA models, the outdoor fan motor is a PSC type. A fan relay on the control board turns the fan off and on by opening and closing a high voltage circuit to the motor. It does not change speeds between low and high stage operation.

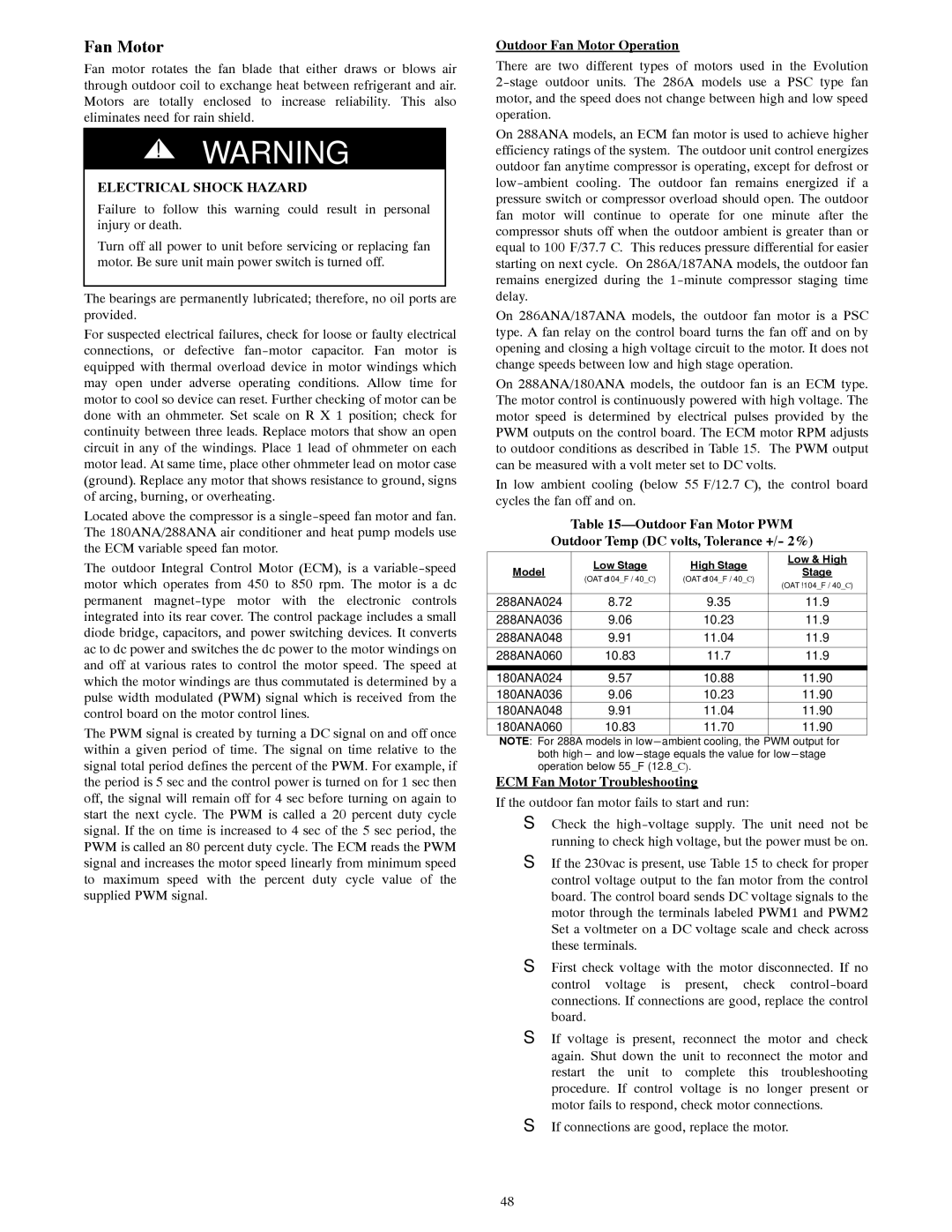

On 288ANA/180ANA models, the outdoor fan is an ECM type. The motor control is continuously powered with high voltage. The motor speed is determined by electrical pulses provided by the PWM outputs on the control board. The ECM motor RPM adjusts to outdoor conditions as described in Table 15. The PWM output can be measured with a volt meter set to DC volts.

In low ambient cooling (below 55°F/12.7°C), the control board cycles the fan off and on.

Table 15—Outdoor Fan Motor PWM

Outdoor Temp (DC volts, Tolerance +/- 2%)

| | Low Stage | High Stage | Low & High |

| Model | Stage |

| (OAT≤104_F / 40_C) | (OAT≤104_F / 40_C) |

| | (OAT>104_F / 40_C) |

| | | |

| | | | |

| 288ANA024 | 8.72 | 9.35 | 11.9 |

| | | | |

| 288ANA036 | 9.06 | 10.23 | 11.9 |

| | | | |

| 288ANA048 | 9.91 | 11.04 | 11.9 |

| | | | |

| 288ANA060 | 10.83 | 11.7 | 11.9 |

| | | | |

| | | | |

| 180ANA024 | 9.57 | 10.88 | 11.90 |

| 180ANA036 | 9.06 | 10.23 | 11.90 |

| 180ANA048 | 9.91 | 11.04 | 11.90 |

| 180ANA060 | 10.83 | 11.70 | 11.90 |

NOTE: For 288A models in low---ambient cooling, the PWM output for both high --- and low---stage equals the value for low---stage operation below 55_F (12.8_C).

ECM Fan Motor Troubleshooting

If the outdoor fan motor fails to start and run:

SCheck the high-voltage supply. The unit need not be running to check high voltage, but the power must be on.

SIf the 230vac is present, use Table 15 to check for proper control voltage output to the fan motor from the control board. The control board sends DC voltage signals to the motor through the terminals labeled PWM1 and PWM2 Set a voltmeter on a DC voltage scale and check across these terminals.

SFirst check voltage with the motor disconnected. If no control voltage is present, check control-board connections. If connections are good, replace the control board.

SIf voltage is present, reconnect the motor and check again. Shut down the unit to reconnect the motor and restart the unit to complete this troubleshooting procedure. If control voltage is no longer present or motor fails to respond, check motor connections.

SIf connections are good, replace the motor.