Contents

Epson Stylus Photo R300/R310

Page

Precautions

About This Manual

Revision Status

Contents

Troubleshooting

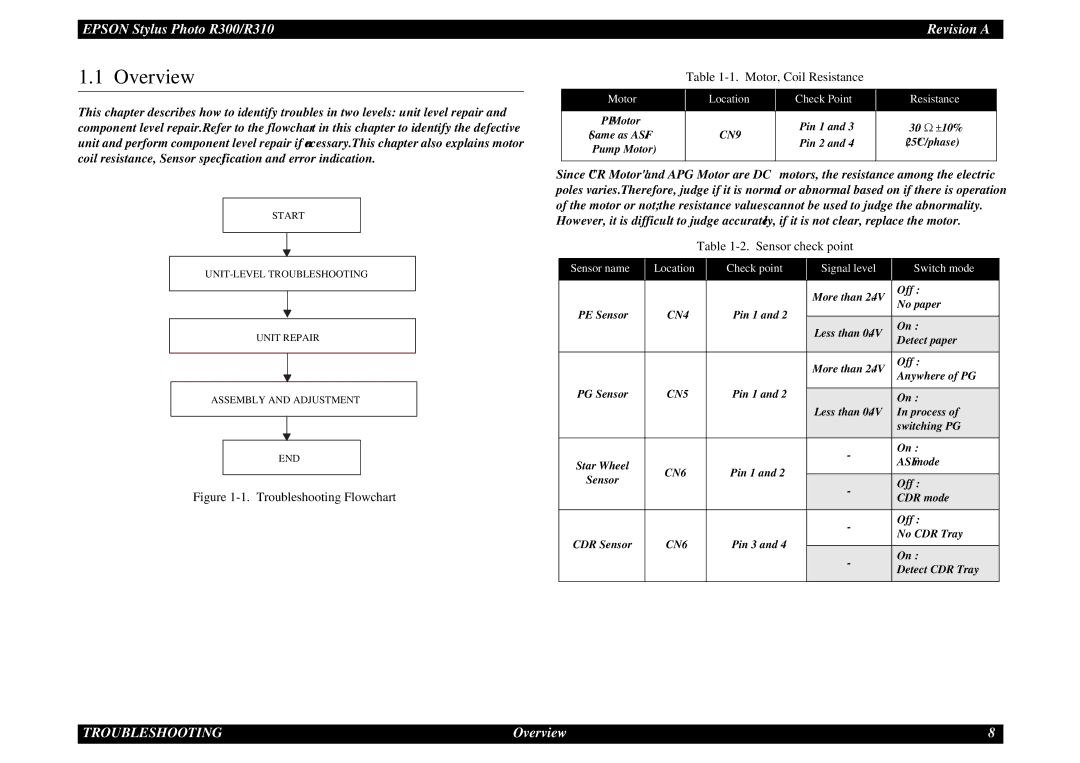

Troubleshooting Flowchart Motor, Coil Resistance

Sensor check point

LED/LCD Indication and STM3

Reaches about 90%

Data error

Troubleshooting

This error is detected when CD/DVD Tray

Unit Level Troubleshooting

Check Points for Communication Error to Each Phenomenon

Check Points for Paper Out Error to Each Phenomenon

Is ejected without being set at the print Start position

Lever, Change

Check Points for Paper Jam Error to Each Phenomenon

Occurrence Phenomenon Detail Faulty Part Check Point Remedy

Paper Guide, Upper

Check Points for CD/DVD Guide Error to Each Phenomenon

Check Points for CD/DVD Tray Error to Each Phenomenon

CDR/DVDR

10. Check points for Memory Card Error to Each Phenomenon

11. Check Points for Fatal Error to Each Phenomenon

13. Check Points for Abnormal Sound

14. Check Points for Defective Print Quality

Refer to Section

At operation

LD Roller

With a soft cloth

Disassembly and Assembly

Precautions

Service Completion Pre-Shipment Check List

Tools

Pre-Shipment Checks

Tools

Disassembly and Assembly

† Caution for disassembly/assembly of Printer Mechanism

† How to secure the quality for reassembled products

Disassembly

Removing Paper Support Assy

† External View

Removing Housing, Upper

Removing Housing, Upper

Reinstalling Printer Cover

Removing Housing, Middle

Paper Support Assy./Housing, Upper

Mounting Panel FFC

Removing Porous Pad, Paper Guide, Front

Vertical Direction 4 ± 1mm Horizontal Direction 1-2mm

Removing Panel Board

14. Reinstalling Stacker Assy

Removing Stacker Assy

Connectors connected to C536 Main Board

Removing Main Board

Assy. with a two-sided tape

„ Make sure to match Panel FFC and the lateral face

Shield Plate, M/B and then attach it to Main Board

Adjustment † Required

Removing ASF Assy

18. Removing ASF Assy

Torsion Spring

Removing Holder, Shaft Assy

20. Removing Holder, Shaft Assy

† Reinstalling LD Roller

„ Removing LD Roller

LD Roller

Removing CR Motor

Removing APG Assy

26. Removing APG Assy

PG Adjustment

Removing Print Head

Removing Carriage Unit

29. Removing Carriage Unit

30. Removing Carriage Unit

„ Removing Pulley, Driven

„ Removing CR Encoder Sensor Board

„ Removing PW Sensor Board

„ Removing Csic Board

Slider, Holder, Scale

Adjustment † Required

Removing Paper Guide, Upper

Upper

Removing Printer Mechanism/ Housing, Lower

38. Removing Printer Mechanism/Housing, Lower

Not to drop and damage them

† When lifting up Printer Mechanism, Lever, Change

Combination Gear, 27.2, 19.2 may detach and drop. Take care

42. Installing Waste Ink Pads

Left

Removing Power Supply Unit

Removing CDR Guide Assy

47. Removing CDR Guide Assy

49. Removing CDR Guide Assy

† External View † Procedure for Removing

Removing Ink System

† Do not remove the ink tube which is connected to Cap Assy

Pump Assy

52. Connecting Point for the ink tube

Disassembly and Assembly

Removing Paper Guide, Front/Roller EJ Assy

Transform Star Wheels of Frame EJ Assy

55. Removing Paper Guide, Front/Roller EJ Assy

56. Removing Paper Guide, Front/Roller EJ Assy

Adequate dose to the specified points

Removing PF Motor

Adjustment

Servicing Adjustment Item List

Adjustment Items

Maintenance Functions

Function Item Purpose Adjustment Outline Tool Used Media

Check Pattern Printing

Appendix

Replacement Part-Based Adjustment Priorities

Adjustment Item

Paper Guide Front Removal

Head ID Input

Market Setting

USB ID Input

Head Angular Adjustment

Bi-d Adjustment

PW Sensor Adjustment

First Dot Adjustment

Offset Input for CR Motor Calorific Limitation

9 A4 Normal Paper Print

10 A4 Photo Quality Inkjet Paper Print

11 A4 Photo Paper/ Glossy Photo Paper print

PG Adjustment

Setting PG Position

Setting Thickness Gauge

12. PG Checking

Maintenance

Cleaning

Service Maintenance

Display for Status Monitor

Lubrication

Lubrication Point

10mm

Right side surface of smaller shaft of Frame EJ

Inside periphery surface of Cam, CR, Right

Pulley, Driven Assy

Overview 100

Overview 101

Appendix

Exploded Diagram Electrical Circuits

Page

Page

Model PM-D750, Stylus Photo R300/310

Model Stylus Photo R300/310

Board C536PNL