EPSON Stylus Photo R300/R310 | Revision A |

Table 1-14. Check Points for Defective Print Quality

Occurrence Timing

Position of CR

Phenomenon Detail

Faulty Part/

Part Name

Check Point

Remedy

At operation

-

[Phenomenon 1]

When the printer is performing the Cleaning task, the ink is not drained into "Waste Ink Pad" in spite of the correct function of "Pump Unit".

The ink is not absorbed from "Print Head" to the Cap at all.

[Phenomenon 2]

When the printer is performing the Cleaning task, the ink is drained into "Waste Ink Pad". (This indicates that both of "Pump Unit" and "Cap Unit" are working correctly.) However, missing dots is not solved at certain nozzles even performing the Cleaning several times.

[Phenomenon 3]

When the printer is performing the Cleaning task, the ink is drained into "Waste Ink Pad". (This indicates that both of "Pump Unit" and "Cap Unit" work correctly.) However, the wiping function is not executed correctly and some different colors of ink mix together.

[Phenomenon 4]

When the printer is performing the Cleaning task, the ink is drained into "Waste Ink Pad". However, some missing dots occurs while printing.

[Phenomenon 5]

When the printer is performing the Cleaning task, the ink is drained into "Waste Ink Pad". However, missing dot occurs and the points where it occurs varies in every movement of the Cleaning.

Ink System

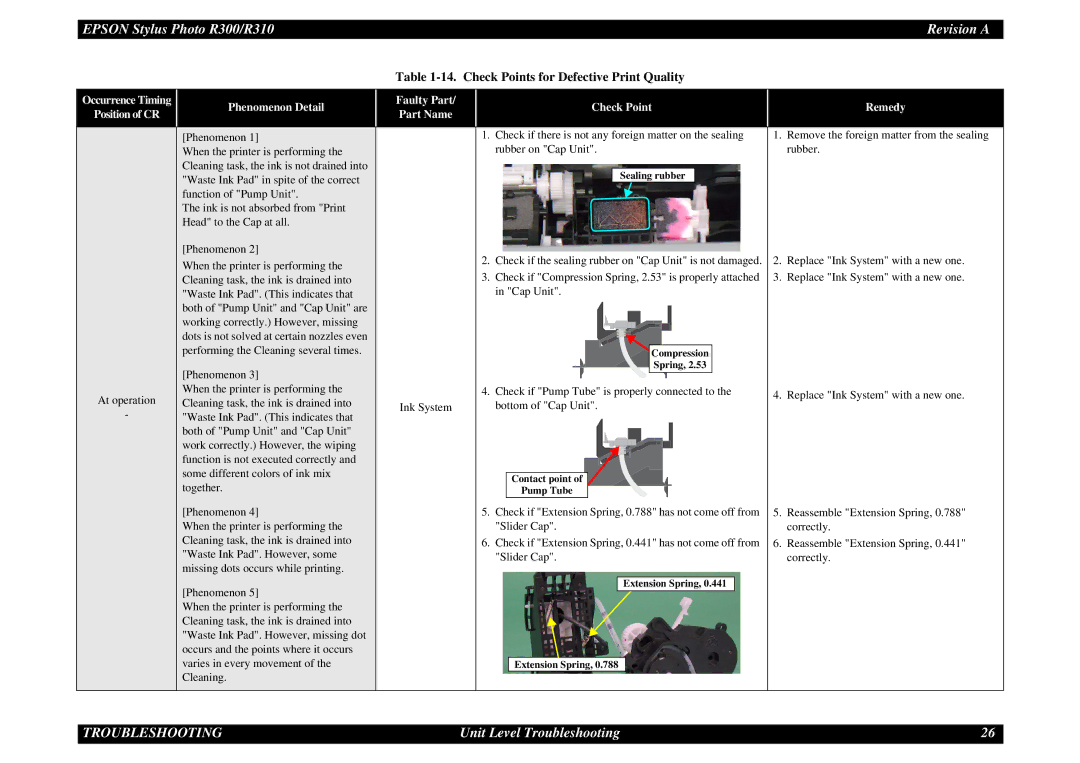

1.Check if there is not any foreign matter on the sealing rubber on "Cap Unit".

Sealing rubber

2.Check if the sealing rubber on "Cap Unit" is not damaged.

3.Check if "Compression Spring, 2.53" is properly attached in "Cap Unit".

Compression

Spring, 2.53

4.Check if "Pump Tube" is properly connected to the bottom of "Cap Unit".

Contact point of

Pump Tube

5.Check if "Extension Spring, 0.788" has not come off from "Slider Cap".

6.Check if "Extension Spring, 0.441" has not come off from "Slider Cap".

Extension Spring, 0.441

Extension Spring, 0.788

1.Remove the foreign matter from the sealing rubber.

2.Replace "Ink System" with a new one.

3.Replace "Ink System" with a new one.

4. Replace "Ink System" with a new one.

5.Reassemble "Extension Spring, 0.788" correctly.

6.Reassemble "Extension Spring, 0.441" correctly.

TROUBLESHOOTING | Unit Level Troubleshooting | 26 |