EPSON Stylus Photo R300/R310 | Revision A |

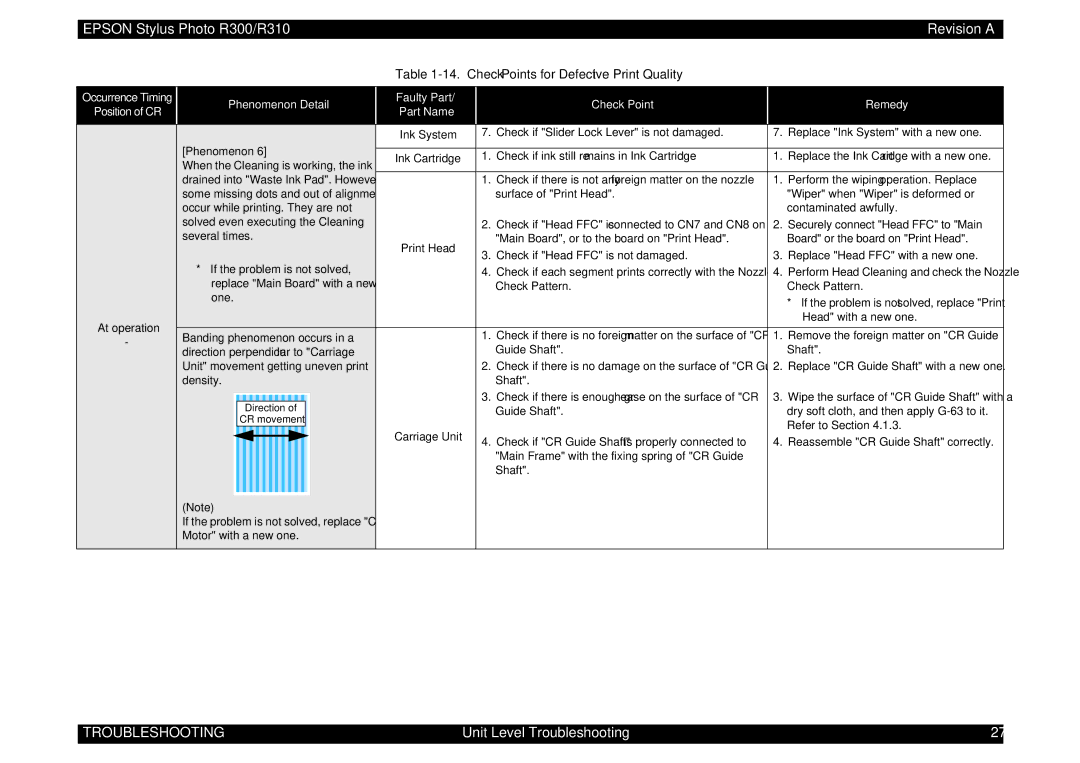

Table 1-14. Check Points for Defective Print Quality

Occurrence Timing

Position of CR

Phenomenon Detail

Faulty Part/

Part Name

Check Point

Remedy

At operation

-

Ink System | 7. Check if "Slider Lock Lever" is not damaged. | 7. Replace "Ink System" with a new one. |

[Phenomenon 6] | Ink Cartridge | 1. | Check if ink still remains in Ink Cartridge | 1. | Replace the Ink Cartridge with a new one. | |

When the Cleaning is working, the ink is | ||||||

|

|

|

|

| ||

drained into "Waste Ink Pad". However, |

| 1. | Check if there is not any foreign matter on the nozzle | 1. | Perform the wiping operation. Replace | |

some missing dots and out of alignment |

|

| surface of "Print Head". |

| "Wiper" when "Wiper" is deformed or | |

occur while printing. They are not |

|

|

|

| contaminated awfully. | |

solved even executing the Cleaning |

| 2. | Check if "Head FFC" is connected to CN7 and CN8 on | 2. | Securely connect "Head FFC" to "Main | |

several times. | Print Head |

| "Main Board", or to the board on "Print Head". |

| Board" or the board on "Print Head". | |

| 3. | Check if "Head FFC" is not damaged. | 3. | Replace "Head FFC" with a new one. | ||

* If the problem is not solved, |

| |||||

| 4. | Check if each segment prints correctly with the Nozzle | 4. | Perform Head Cleaning and check the Nozzle | ||

replace "Main Board" with a new |

|

| Check Pattern. |

| Check Pattern. | |

one. |

|

|

|

| * If the problem is not solved, replace "Print | |

|

|

|

|

| ||

|

|

|

|

| Head" with a new one. | |

Banding phenomenon occurs in a |

| 1. | Check if there is no foreign matter on the surface of "CR | 1. | Remove the foreign matter on "CR Guide | |

direction perpendicular to "Carriage |

|

| Guide Shaft". |

| Shaft". | |

Unit" movement getting uneven print |

| 2. | Check if there is no damage on the surface of "CR Guide | 2. | Replace "CR Guide Shaft" with a new one. | |

density. |

|

| Shaft". |

|

| |

Direction of |

| 3. | Check if there is enough grease on the surface of "CR | 3. | Wipe the surface of "CR Guide Shaft" with a | |

|

| Guide Shaft". |

| dry soft cloth, and then apply | ||

CR movement |

|

|

|

| Refer to Section 4.1.3. | |

| Carriage Unit |

|

|

| ||

| 4. | Check if "CR Guide Shaft" is properly connected to | 4. | Reassemble "CR Guide Shaft" correctly. | ||

|

| |||||

|

|

| "Main Frame" with the fixing spring of "CR Guide |

|

| |

|

|

| Shaft". |

|

| |

(Note) |

|

|

|

|

| |

If the problem is not solved, replace "CR |

|

|

|

|

| |

Motor" with a new one. |

|

|

|

|

|

TROUBLESHOOTING | Unit Level Troubleshooting | 27 |