EPSON Stylus Photo R300/R310 |

|

| Revision A |

| ||

|

| Table |

|

|

| |

|

|

|

|

|

|

|

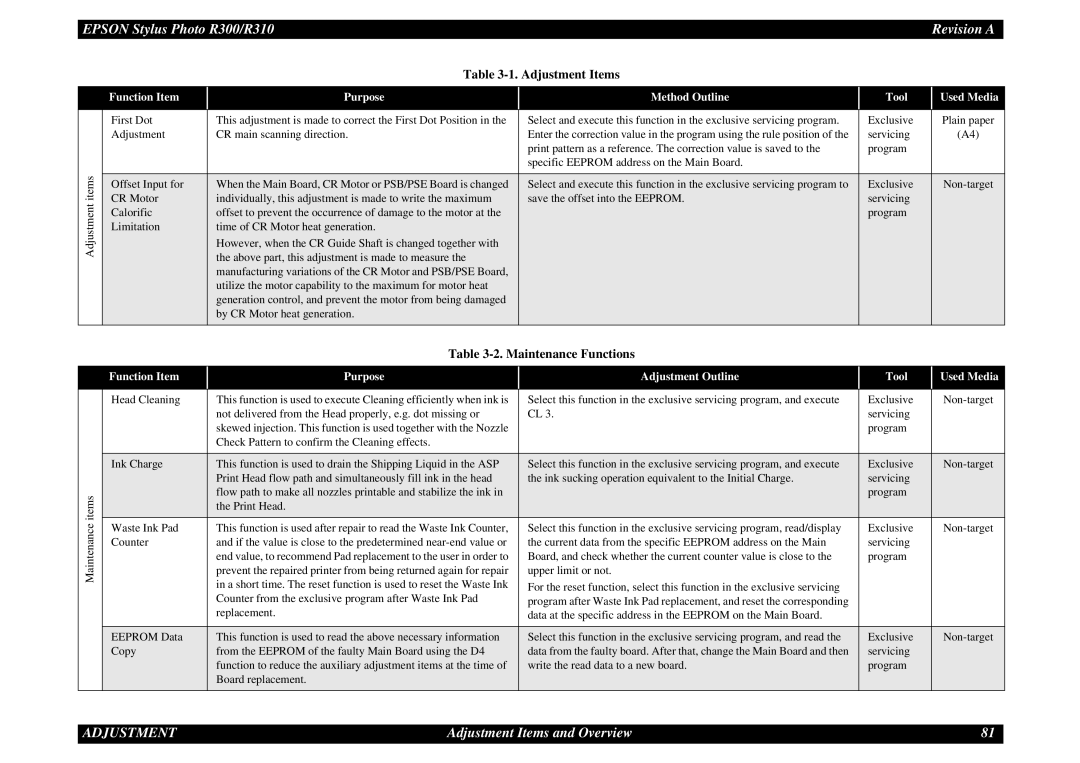

| Function Item | Purpose | Method Outline | Tool | Used Media |

|

|

|

|

|

|

|

|

| First Dot | This adjustment is made to correct the First Dot Position in the | Select and execute this function in the exclusive servicing program. | Exclusive | Plain paper |

|

| Adjustment | CR main scanning direction. | Enter the correction value in the program using the rule position of the | servicing | (A4) |

|

|

|

| print pattern as a reference. The correction value is saved to the | program |

|

|

|

|

| specific EEPROM address on the Main Board. |

|

|

|

items |

|

|

|

|

|

|

Offset Input for | When the Main Board, CR Motor or PSB/PSE Board is changed | Select and execute this function in the exclusive servicing program to | Exclusive |

| ||

|

| |||||

Adjustment | CR Motor | individually, this adjustment is made to write the maximum | save the offset into the EEPROM. | servicing |

|

|

Calorific | offset to prevent the occurrence of damage to the motor at the |

| program |

|

| |

|

|

|

| |||

| Limitation | time of CR Motor heat generation. |

|

|

|

|

|

| However, when the CR Guide Shaft is changed together with |

|

|

|

|

|

| the above part, this adjustment is made to measure the |

|

|

|

|

|

| manufacturing variations of the CR Motor and PSB/PSE Board, |

|

|

|

|

|

| utilize the motor capability to the maximum for motor heat |

|

|

|

|

|

| generation control, and prevent the motor from being damaged |

|

|

|

|

|

| by CR Motor heat generation. |

|

|

|

|

|

| Table |

|

|

| |

|

|

|

|

|

|

|

| Function Item | Purpose | Adjustment Outline | Tool | Used Media |

|

|

|

|

|

|

|

|

| Head Cleaning | This function is used to execute Cleaning efficiently when ink is | Select this function in the exclusive servicing program, and execute | Exclusive |

| |

|

| not delivered from the Head properly, e.g. dot missing or | CL 3. | servicing |

|

|

|

| skewed injection. This function is used together with the Nozzle |

| program |

|

|

|

| Check Pattern to confirm the Cleaning effects. |

|

|

|

|

|

|

|

|

|

|

|

| Ink Charge | This function is used to drain the Shipping Liquid in the ASP | Select this function in the exclusive servicing program, and execute | Exclusive |

| |

|

| Print Head flow path and simultaneously fill ink in the head | the ink sucking operation equivalent to the Initial Charge. | servicing |

|

|

items |

| flow path to make all nozzles printable and stabilize the ink in |

| program |

|

|

| the Print Head. |

|

|

|

| |

|

|

|

|

|

| |

Maintenance | Waste Ink Pad | This function is used after repair to read the Waste Ink Counter, | Select this function in the exclusive servicing program, read/display | Exclusive |

| |

Counter | and if the value is close to the predetermined | the current data from the specific EEPROM address on the Main | servicing |

|

| |

|

|

| ||||

|

| end value, to recommend Pad replacement to the user in order to | Board, and check whether the current counter value is close to the | program |

|

|

|

| prevent the repaired printer from being returned again for repair | upper limit or not. |

|

|

|

|

| in a short time. The reset function is used to reset the Waste Ink | For the reset function, select this function in the exclusive servicing |

|

|

|

|

| Counter from the exclusive program after Waste Ink Pad | program after Waste Ink Pad replacement, and reset the corresponding |

|

|

|

|

| replacement. | data at the specific address in the EEPROM on the Main Board. |

|

|

|

|

|

|

|

|

|

|

| EEPROM Data | This function is used to read the above necessary information | Select this function in the exclusive servicing program, and read the | Exclusive |

| |

| Copy | from the EEPROM of the faulty Main Board using the D4 | data from the faulty board. After that, change the Main Board and then | servicing |

|

|

|

| function to reduce the auxiliary adjustment items at the time of | write the read data to a new board. | program |

|

|

|

| Board replacement. |

|

|

|

|

|

|

|

|

|

|

|

ADJUSTMENT | Adjustment Items and Overview | 81 |