EPSON Stylus Photo R300/R310 | Revision A |

3.1 Adjustment Items and Overview

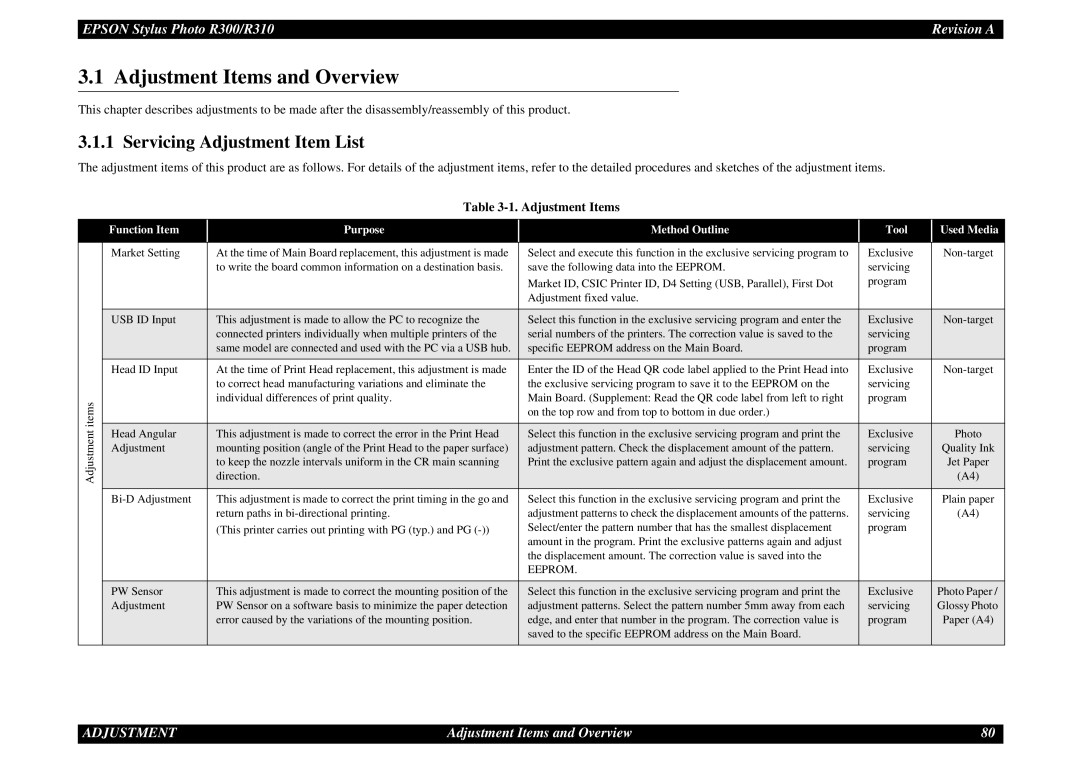

This chapter describes adjustments to be made after the disassembly/reassembly of this product.

3.1.1 Servicing Adjustment Item List

The adjustment items of this product are as follows. For details of the adjustment items, refer to the detailed procedures and sketches of the adjustment items.

Table 3-1. Adjustment Items

Function Item

Purpose

Method Outline

Tool

Used Media

| Market Setting | At the time of Main Board replacement, this adjustment is made | Select and execute this function in the exclusive servicing program to | Exclusive | |

|

| to write the board common information on a destination basis. | save the following data into the EEPROM. | servicing |

|

|

|

| Market ID, CSIC Printer ID, D4 Setting (USB, Parallel), First Dot | program |

|

|

|

| Adjustment fixed value. |

|

|

|

|

|

|

|

|

| USB ID Input | This adjustment is made to allow the PC to recognize the | Select this function in the exclusive servicing program and enter the | Exclusive | |

|

| connected printers individually when multiple printers of the | serial numbers of the printers. The correction value is saved to the | servicing |

|

|

| same model are connected and used with the PC via a USB hub. | specific EEPROM address on the Main Board. | program |

|

| Head ID Input | At the time of Print Head replacement, this adjustment is made | Enter the ID of the Head QR code label applied to the Print Head into | Exclusive | |

|

| to correct head manufacturing variations and eliminate the | the exclusive servicing program to save it to the EEPROM on the | servicing |

|

items |

| individual differences of print quality. | Main Board. (Supplement: Read the QR code label from left to right | program |

|

|

| on the top row and from top to bottom in due order.) |

|

| |

|

|

|

|

| |

|

|

|

|

|

|

Adjustment | Head Angular | This adjustment is made to correct the error in the Print Head | Select this function in the exclusive servicing program and print the | Exclusive | Photo |

Adjustment | direction. | adjustment pattern. Check the displacement amount of the pattern. | servicing | (A4) | |

| mounting position (angle of the Print Head to the paper surface) | Quality Ink | |||

|

| to keep the nozzle intervals uniform in the CR main scanning | Print the exclusive pattern again and adjust the displacement amount. | program | Jet Paper |

|

|

|

|

|

|

| This adjustment is made to correct the print timing in the go and | Select this function in the exclusive servicing program and print the | Exclusive | Plain paper | |

|

| return paths in | adjustment patterns to check the displacement amounts of the patterns. | servicing | (A4) |

|

| (This printer carries out printing with PG (typ.) and PG | Select/enter the pattern number that has the smallest displacement | program |

|

|

|

| amount in the program. Print the exclusive patterns again and adjust |

|

|

|

|

| the displacement amount. The correction value is saved into the |

|

|

|

|

| EEPROM. |

|

|

|

|

|

|

|

|

| PW Sensor | This adjustment is made to correct the mounting position of the | Select this function in the exclusive servicing program and print the | Exclusive | Photo Paper / |

| Adjustment | PW Sensor on a software basis to minimize the paper detection | adjustment patterns. Select the pattern number 5mm away from each | servicing | Glossy Photo |

|

| error caused by the variations of the mounting position. | edge, and enter that number in the program. The correction value is | program | Paper (A4) |

|

|

| saved to the specific EEPROM address on the Main Board. |

|

|

|

|

|

|

|

|

ADJUSTMENT | Adjustment Items and Overview | 80 |