Wire Feed Arc Welder

Soudeur à l’Arc Alimenté en Fil

Soldadora Por Arco Con Alimentación de Cable

Notes

Notes

Notas

Operating Instructions & Parts Manual | Models WG2060 and WG2064 |

|

|

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or property damage! Retain instructions for future reference.

Wire Feed | UA |

|

|

|

|

| Need |

| M | ||

|

|

|

|

|

|

| URAN | CE |

| ||

|

|

|

|

|

| SS |

| ||||

|

|

|

|

| A |

|

| P |

| ||

|

|

|

|

|

|

| R |

| |||

|

|

|

| Y |

|

|

| O | |||

|

|

| T |

|

|

|

| G | |||

|

| L | I |

|

|

|

|

| R | ||

| Q |

| Assistance? | A | |||||||

Arc Welder |

|

|

| ||||||||

Call Us First! | |||||||||||

| |||||||||||

BUILT TO LAST

DescriptionUnpacking

Welding accessories are packed inside

Heat | Circuit Breaker or |

Selector | Slow Blow Fuse |

|

|

This Campbell Hausfeld wire feed welder is designed to be used on standard 115V household current. The welder is equipped with infinite wire speed control to accurately select the proper wire feed rate needed for various welding conditions. Internal components are thermostatically protected.

This welding system is designed for use with the Flux Cored Arc Welding (FCAW) or the Gas Metal Arc Welding (GMAW) process. As delivered from the factory, this welder can weld with .024” (.6mm) to .030” (.8mm) diameter wire in MIG and .030” (.8mm) to .035” (.9mm) diameter wire in flux core. A starter spool of .035” (.9mm) flux cored wire is included.

the wire feed compartment on the

side of the welder. When unpacking, inspect carefully for any damage that may have occurred during transit. Make sure any loose fittings and screws, etc., are tightened before putting unit into service.

Report any missing or damaged items by calling

CIRCUIT REQUIREMENTS

This equipment

! CAUTION requires a dedicated 115 volt circuit. Refer to the following chart for correct circuit breaker or fuse rating. Do not run other appliances, lights or tools on this circuit while operating this equipment. Extension cords are not recommended. Blown fuses and tripped circuit breakers can result from failure to comply with this recommendation.

15 amp | |||||

|

|

|

|

|

|

4 | 20 amp |

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

See page 7 for supply cable replacement instructions.

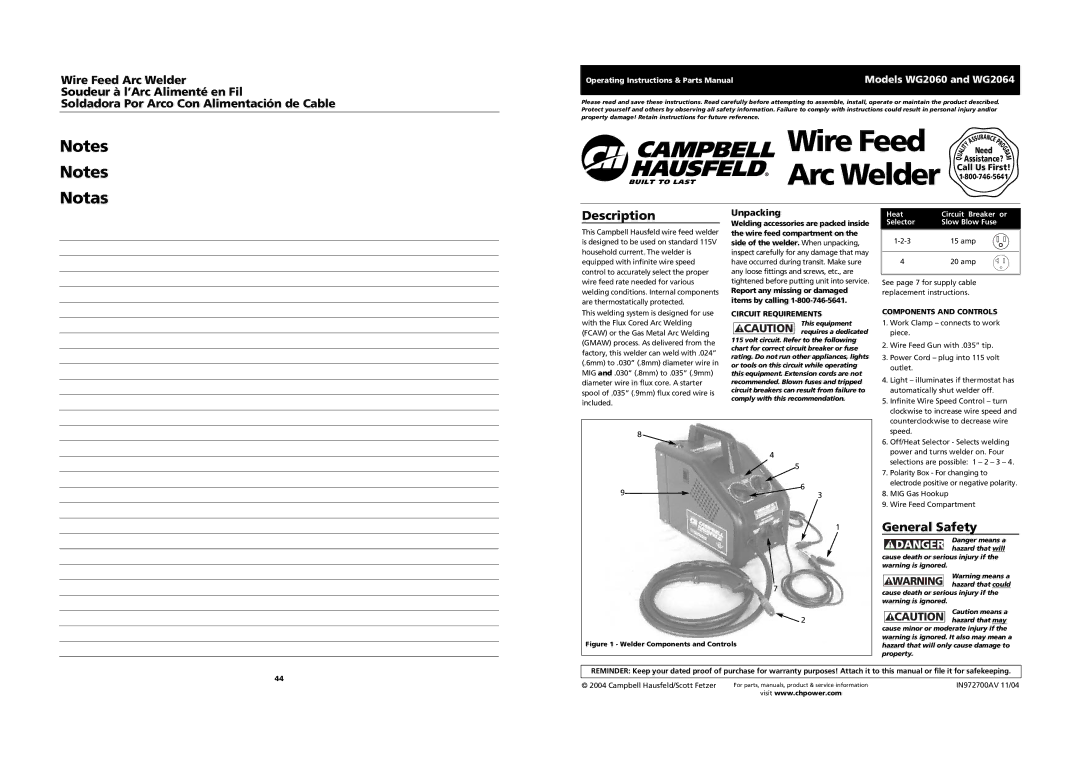

COMPONENTS AND CONTROLS

1. Work Clamp – connects to work |

piece. |

2. Wire Feed Gun with .035” tip. |

3. Power Cord – plug into 115 volt |

outlet. |

4. Light – illuminates if thermostat has |

automatically shut welder off. |

5. Infinite Wire Speed Control – turn |

clockwise to increase wire speed and |

counterclockwise to decrease wire |

speed. |

| 8 | |

| 4 | |

| 5 | |

9 | 6 | |

3 | ||

|

1

7

![]() 2

2

Figure 1 - Welder Components and Controls

6. Off/Heat Selector - Selects welding |

power and turns welder on. Four |

selections are possible: 1 – 2 – 3 – 4. |

7. Polarity Box - For changing to |

electrode positive or negative polarity. |

8. MIG Gas Hookup |

9. Wire Feed Compartment |

General Safety

Danger means a hazard that will

cause death or serious injury if the warning is ignored.

Warning means a ! WARNING hazard that could

cause death or serious injury if the warning is ignored.

Caution means a ! CAUTION hazard that may

cause minor or moderate injury if the warning is ignored. It also may mean a hazard that will only cause damage to property.

44

REMINDER: Keep your dated proof of purchase for warranty purposes! Attach it to this manual or file it for safekeeping.

© 2004 Campbell Hausfeld/Scott Fetzer | For parts, manuals, product & service information | IN972700AV 11/04 |

visit www.chpower.com