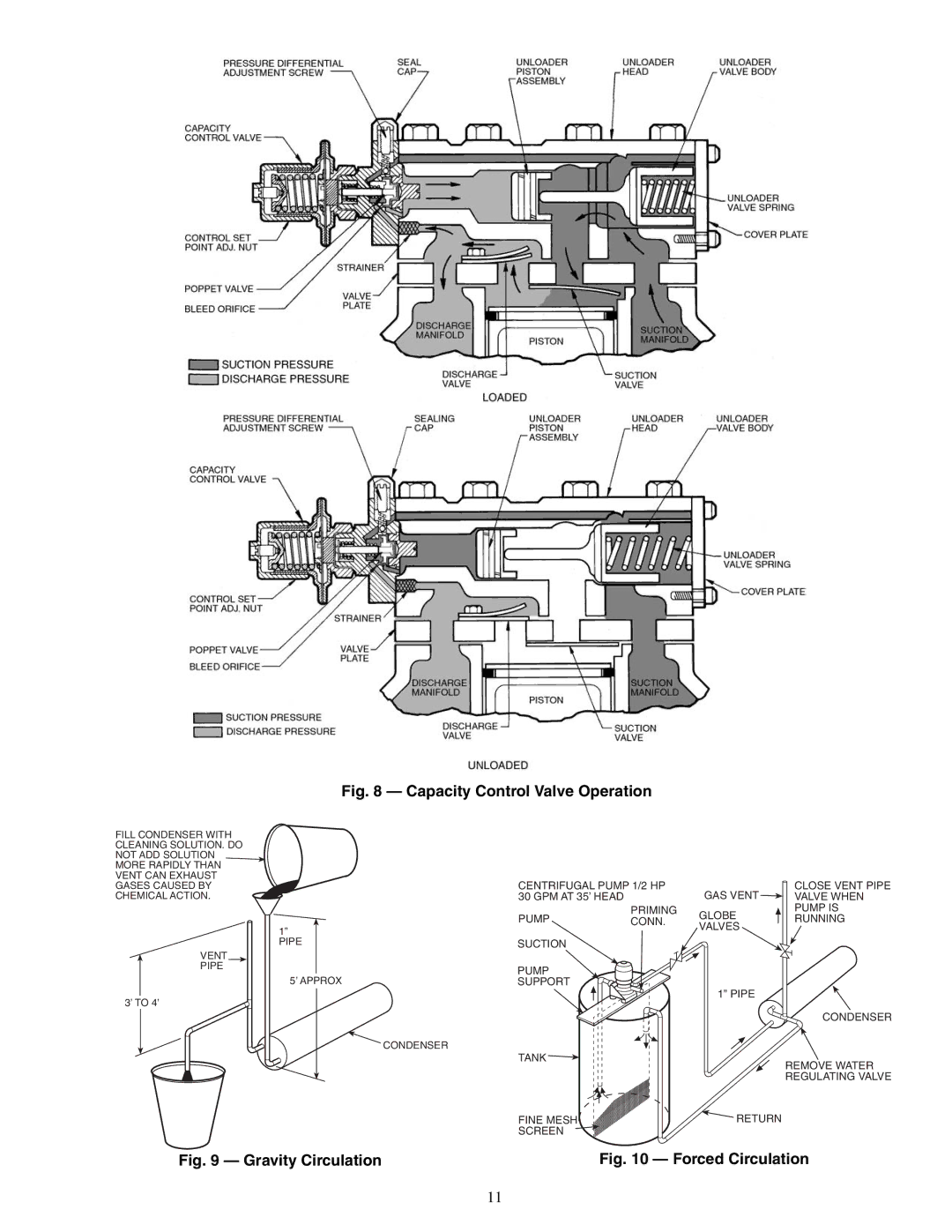

Fig. 8 — Capacity Control Valve Operation

FILL CONDENSER WITH

CLEANING SOLUTION. DO

NOT ADD SOLUTION

MORE RAPIDLY THAN

VENT CAN EXHAUST

GASES CAUSED BY

CHEMICAL ACTION.

1”

PIPE

VENT

PIPE

5’ APPROX

3’ TO 4’

CENTRIFUGAL PUMP 1/2 HP | GAS VENT | CLOSE VENT PIPE | |

30 GPM AT 35’ HEAD |

| VALVE WHEN | |

| PRIMING | GLOBE | PUMP IS |

PUMP | CONN. | RUNNING | |

|

| VALVES |

|

SUCTION |

|

|

|

PUMP

SUPPORT

1” PIPE

CONDENSER

TANK  LEGEND

LEGEND

CONDENSER

REMOVE WATER

Fig. 9 — Gravity Circulation

1— Oil Pressure Relief Valve ![]() 5 — EccentricREGULATINGShaft VALVE

5 — EccentricREGULATINGShaft VALVE

2 — Piston and Eccentric | 6 — Eccentric Strap Side |

Strap Assembly | Shield |

3— Motor End Counterweight 7 — Oil Suction Tube

FINE MESHRETURN

4— Oil Return Check Valve 8 — Pump End Counterweight

SCREEN

Fig. 11 — Compressor

Fig. 10 — Forced Circulation

(Bottom Plate Removed)

11