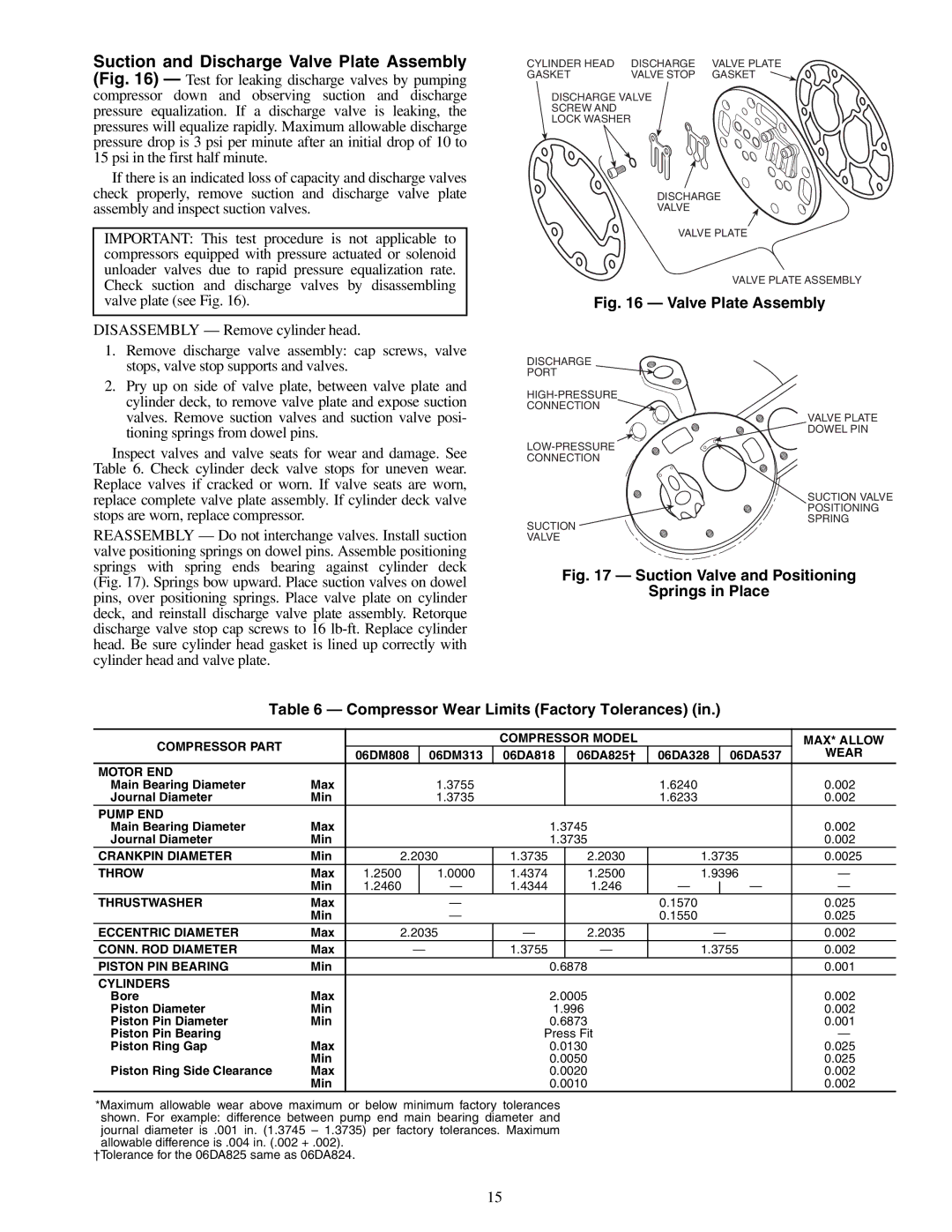

Suction and Discharge Valve Plate Assembly (Fig. 16) — Test for leaking discharge valves by pumping compressor down and observing suction and discharge pressure equalization. If a discharge valve is leaking, the pressures will equalize rapidly. Maximum allowable discharge pressure drop is 3 psi per minute after an initial drop of 10 to 15 psi in the first half minute.

If there is an indicated loss of capacity and discharge valves check properly, remove suction and discharge valve plate assembly and inspect suction valves.

IMPORTANT: This test procedure is not applicable to compressors equipped with pressure actuated or solenoid unloader valves due to rapid pressure equalization rate. Check suction and discharge valves by disassembling valve plate (see Fig. 16).

DISASSEMBLY — Remove cylinder head.

1.Remove discharge valve assembly: cap screws, valve stops, valve stop supports and valves.

2.Pry up on side of valve plate, between valve plate and cylinder deck, to remove valve plate and expose suction valves. Remove suction valves and suction valve posi- tioning springs from dowel pins.

Inspect valves and valve seats for wear and damage. See Table 6. Check cylinder deck valve stops for uneven wear. Replace valves if cracked or worn. If valve seats are worn,

CYLINDER HEAD | DISCHARGE | VALVE PLATE |

GASKET | VALVE STOP | GASKET |

DISCHARGE VALVE

SCREW AND

LOCK WASHER

DISCHARGE

VALVE

VALVE PLATE

VALVE PLATE ASSEMBLY

Fig. 16 — Valve Plate Assembly

DISCHARGE

PORT

![]()

![]()

VALVE PLATE

![]() DOWEL PIN

DOWEL PIN

replace complete valve plate assembly. If cylinder deck valve stops are worn, replace compressor.

REASSEMBLY — Do not interchange valves. Install suction valve positioning springs on dowel pins. Assemble positioning springs with spring ends bearing against cylinder deck

SUCTION VALVE

SUCTION VALVE POSITIONING SPRING

(Fig. 17). Springs bow upward. Place suction valves on dowel pins, over positioning springs. Place valve plate on cylinder deck, and reinstall discharge valve plate assembly. Retorque discharge valve stop cap screws to 16 lb-ft. Replace cylinder head. Be sure cylinder head gasket is lined up correctly with cylinder head and valve plate.

Fig. 17 — Suction Valve and Positioning

Springs in Place

Table 6 — Compressor Wear Limits (Factory Tolerances) (in.)

COMPRESSOR PART |

|

|

|

| COMPRESSOR MODEL |

|

|

| MAX* ALLOW | |

| 06DM808 |

| 06DM313 | 06DA818 | 06DA825† | 06DA328 |

| 06DA537 | WEAR | |

|

|

|

| |||||||

MOTOR END |

|

|

|

|

|

|

|

|

|

|

Main Bearing Diameter | Max |

| 1.3755 |

|

| 1.6240 |

|

| 0.002 | |

Journal Diameter | Min |

| 1.3735 |

|

| 1.6233 |

|

| 0.002 | |

PUMP END |

|

|

|

|

|

|

|

|

|

|

Main Bearing Diameter | Max |

|

|

| 1.3745 |

|

|

| 0.002 | |

Journal Diameter | Min |

|

|

| 1.3735 |

|

|

| 0.002 | |

CRANKPIN DIAMETER | Min | 2.2030 | 1.3735 | 2.2030 | 1.3735 | 0.0025 | ||||

THROW | Max | 1.2500 |

| 1.0000 | 1.4374 | 1.2500 | 1.9396 | — | ||

| Min | 1.2460 |

| — | 1.4344 | 1.246 | — |

| — | — |

|

|

| ||||||||

THRUSTWASHER | Max |

|

| — |

|

| 0.1570 |

|

| 0.025 |

| Min |

|

| — |

|

| 0.1550 |

|

| 0.025 |

ECCENTRIC DIAMETER | Max | 2.2035 | — | 2.2035 |

| — | 0.002 | |||

CONN. ROD DIAMETER | Max |

| — | 1.3755 | — | 1.3755 | 0.002 | |||

PISTON PIN BEARING | Min |

|

|

| 0.6878 |

|

|

| 0.001 | |

CYLINDERS |

|

|

|

|

|

|

|

|

|

|

Bore | Max |

|

|

| 2.0005 |

|

|

| 0.002 | |

Piston Diameter | Min |

|

|

| 1.996 |

|

|

| 0.002 | |

Piston Pin Diameter | Min |

|

|

| 0.6873 |

|

|

| 0.001 | |

Piston Pin Bearing |

|

|

|

| Press Fit |

|

|

| — | |

Piston Ring Gap | Max |

|

|

| 0.0130 |

|

|

| 0.025 | |

| Min |

|

|

| 0.0050 |

|

|

| 0.025 | |

Piston Ring Side Clearance | Max |

|

|

| 0.0020 |

|

|

| 0.002 | |

| Min |

|

|

| 0.0010 |

|

|

| 0.002 | |

*Maximum allowable wear above maximum or below minimum factory tolerances shown. For example: difference between pump end main bearing diameter and journal diameter is .001 in. (1.3745 – 1.3735) per factory tolerances. Maximum allowable difference is .004 in. (.002 + .002).

†Tolerance for the 06DA825 same as 06DA824.

15