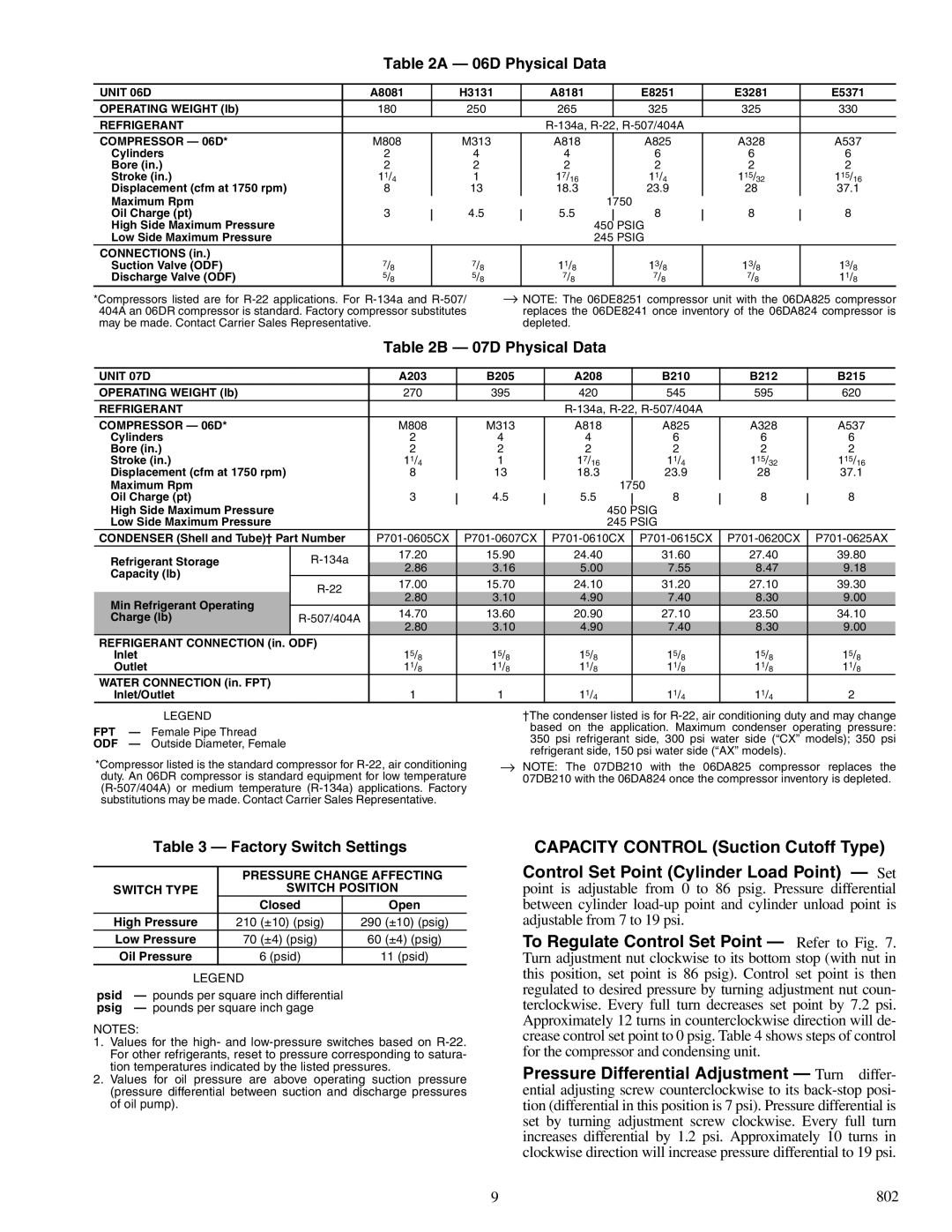

Table 2A — 06D Physical Data

UNIT 06D | A8081 |

| H3131 |

| A8181 |

|

| E8251 |

| E3281 |

| E5371 |

OPERATING WEIGHT (lb) | 180 |

| 250 |

| 265 |

|

| 325 |

| 325 |

| 330 |

REFRIGERANT |

|

|

|

|

|

|

|

| ||||

COMPRESSOR — 06D* | M808 |

| M313 |

| A818 |

|

| A825 |

| A328 |

| A537 |

Cylinders | 2 |

| 4 |

| 4 |

|

| 6 |

| 6 |

| 6 |

Bore (in.) | 2 |

| 2 |

| 2 |

|

| 2 |

| 2 |

| 2 |

Stroke (in.) | 11/4 |

| 1 |

| 17/16 |

|

| 11/4 |

| 115/32 |

| 115/16 |

Displacement (cfm at 1750 rpm) | 8 |

| 13 |

| 18.3 |

|

| 23.9 |

| 28 |

| 37.1 |

Maximum Rpm |

|

|

|

|

|

| 1750 |

|

|

|

| |

Oil Charge (pt) | 3 |

| 4.5 |

| 5.5 |

|

| 8 |

| 8 |

| 8 |

|

|

|

|

| ||||||||

High Side Maximum Pressure |

|

|

|

|

| 450 |

| PSIG |

|

|

|

|

Low Side Maximum Pressure |

|

|

|

|

| 245 PSIG |

|

|

|

| ||

CONNECTIONS (in.) |

|

|

|

|

|

|

|

|

|

|

|

|

Suction Valve (ODF) | 7/8 |

| 7/8 |

| 11/8 |

|

| 13/8 |

| 13/8 |

| 13/8 |

Discharge Valve (ODF) | 5/8 |

| 5/8 |

| 7/8 |

|

| 7/8 |

| 7/8 |

| 11/8 |

*Compressors listed are for

→NOTE: The 06DE8251 compressor unit with the 06DA825 compressor replaces the 06DE8241 once inventory of the 06DA824 compressor is depleted.

Table 2B — 07D Physical Data

UNIT 07D |

| A203 |

| B205 |

| A208 |

|

| B210 |

| B212 |

| B215 |

OPERATING WEIGHT (lb) |

| 270 |

| 395 |

| 420 |

|

| 545 |

| 595 |

| 620 |

REFRIGERANT |

|

|

|

|

|

|

|

|

| ||||

COMPRESSOR — 06D* |

| M808 |

| M313 |

| A818 |

|

| A825 |

| A328 |

| A537 |

Cylinders |

| 2 |

| 4 |

| 4 |

|

| 6 |

| 6 |

| 6 |

Bore (in.) |

| 2 |

| 2 |

| 2 |

|

| 2 |

| 2 |

| 2 |

Stroke (in.) |

| 11/4 |

| 1 |

| 17/16 |

|

| 11/4 |

| 115/32 |

| 115/16 |

Displacement (cfm at 1750 rpm) |

| 8 |

| 13 |

| 18.3 |

|

| 23.9 |

| 28 |

| 37.1 |

Maximum Rpm |

|

|

|

|

|

| 1750 |

|

|

|

| ||

Oil Charge (pt) |

| 3 |

| 4.5 |

| 5.5 |

|

| 8 |

| 8 |

| 8 |

|

|

|

|

|

| ||||||||

High Side Maximum Pressure |

|

|

|

|

|

| 450 |

| PSIG |

|

|

|

|

Low Side Maximum Pressure |

|

|

|

|

|

| 245 PSIG |

|

|

|

| ||

CONDENSER (Shell and Tube)† Part Number |

|

|

|

|

| ||||||||

Refrigerant Storage | 17.20 |

| 15.90 |

| 24.40 |

|

| 31.60 |

| 27.40 |

| 39.80 | |

2.86 |

| 3.16 |

| 5.00 |

|

| 7.55 |

| 8.47 |

| 9.18 | ||

Capacity (lb) |

|

|

|

|

|

|

| ||||||

17.00 |

| 15.70 |

| 24.10 |

|

| 31.20 |

| 27.10 |

| 39.30 | ||

|

|

|

|

|

|

| |||||||

Min Refrigerant Operating | 2.80 |

| 3.10 |

| 4.90 |

|

| 7.40 |

| 8.30 |

| 9.00 | |

|

|

|

|

|

|

| |||||||

| 14.70 |

| 13.60 |

| 20.90 |

|

| 27.10 |

| 23.50 |

| 34.10 | |

Charge (lb) |

|

|

|

|

|

| |||||||

|

| 2.80 |

| 3.10 |

| 4.90 |

|

| 7.40 |

| 8.30 |

| 9.00 |

REFRIGERANT CONNECTION (in. ODF) |

|

|

|

|

|

|

|

|

|

|

|

| |

Inlet |

| 15/8 |

| 15/8 |

| 15/8 |

|

| 15/8 |

| 15/8 |

| 15/8 |

Outlet |

| 11/8 |

| 11/8 |

| 11/8 |

|

| 11/8 |

| 11/8 |

| 11/8 |

WATER CONNECTION (in. FPT) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Inlet/Outlet |

| 1 |

| 1 |

| 11/4 |

|

| 11/4 |

| 11/4 |

| 2 |

LEGEND

FPT — Female Pipe Thread

ODF — Outside Diameter, Female

*Compressor listed is the standard compressor for

†The condenser listed is for

→NOTE: The 07DB210 with the 06DA825 compressor replaces the 07DB210 with the 06DA824 once the compressor inventory is depleted.

Table 3 — Factory Switch Settings

|

| PRESSURE CHANGE AFFECTING | |||

SWITCH TYPE |

| SWITCH POSITION | |||

|

|

| Closed |

| Open |

High Pressure | 210 | (±10) (psig) | 290 | (±10) (psig) | |

Low Pressure | 70 | (±4) (psig) | 60 | (±4) (psig) | |

Oil Pressure |

| 6 (psid) | 11 (psid) | ||

LEGEND

psid — pounds per square inch differential psig — pounds per square inch gage

NOTES:

1.Values for the high- and

2.Values for oil pressure are above operating suction pressure (pressure differential between suction and discharge pressures of oil pump).

CAPACITY CONTROL (Suction Cutoff Type)

Control Set Point (Cylinder Load Point) — Set point is adjustable from 0 to 86 psig. Pressure differential between cylinder

To Regulate Control Set Point — Refer to Fig. 7. Turn adjustment nut clockwise to its bottom stop (with nut in this position, set point is 86 psig). Control set point is then regulated to desired pressure by turning adjustment nut coun- terclockwise. Every full turn decreases set point by 7.2 psi. Approximately 12 turns in counterclockwise direction will de- crease control set point to 0 psig. Table 4 shows steps of control for the compressor and condensing unit.

Pressure Differential Adjustment — Turn differ- ential adjusting screw counterclockwise to its

9 | 802 |