CONTROL

SET POINT

![]() ADJUSTMENT

ADJUSTMENT

NUT

POWER

![]() HEAD

HEAD

PRESSURE

DIFFERENTIAL

ADJUSTMENT

SCREW

![]() VALVE BODY

VALVE BODY

BYPASS

PISTON RING

BYPASS |

|

WITH HOT GAS BYPASS | DIFFERENTIAL SCREW |

TYPE OF UNLOADING ONLY. | |

NOT REQUIRED WITH | SEALING CAP (CAP MUST |

SUCTION CUTOFF TYPE | BE REPLACED TO PREVENT |

UNLOADING. | REFRIGERANT LEAKAGE) |

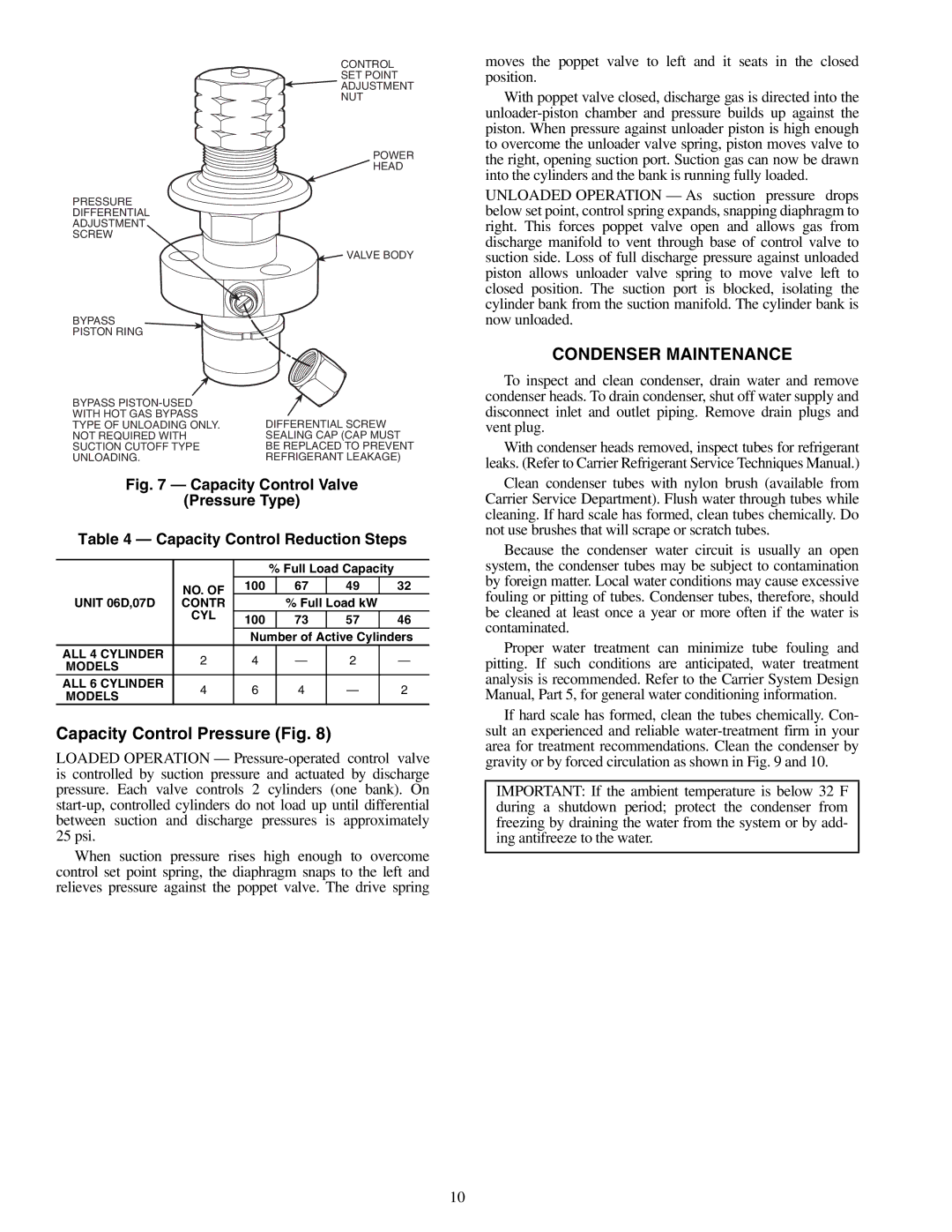

Fig. 7 — Capacity Control Valve

(Pressure Type)

Table 4 — Capacity Control Reduction Steps

|

|

| % Full Load Capacity |

| |||

| NO. OF | 100 |

| 67 | 49 |

| 32 |

UNIT 06D,07D | CONTR |

|

| % Full Load kW |

| ||

| CYL | 100 |

| 73 | 57 |

| 46 |

|

|

|

| ||||

|

| Number of Active Cylinders | |||||

ALL 4 CYLINDER | 2 | 4 |

| — | 2 |

| — |

MODELS |

|

| |||||

|

|

|

|

|

|

| |

ALL 6 CYLINDER | 4 | 6 |

| 4 | — |

| 2 |

MODELS |

|

| |||||

|

|

|

|

|

|

| |

Capacity Control Pressure (Fig. 8)

LOADED OPERATION —

When suction pressure rises high enough to overcome control set point spring, the diaphragm snaps to the left and relieves pressure against the poppet valve. The drive spring

moves the poppet valve to left and it seats in the closed position.

With poppet valve closed, discharge gas is directed into the

UNLOADED OPERATION — As suction pressure drops below set point, control spring expands, snapping diaphragm to right. This forces poppet valve open and allows gas from discharge manifold to vent through base of control valve to suction side. Loss of full discharge pressure against unloaded piston allows unloader valve spring to move valve left to closed position. The suction port is blocked, isolating the cylinder bank from the suction manifold. The cylinder bank is now unloaded.

CONDENSER MAINTENANCE

To inspect and clean condenser, drain water and remove condenser heads. To drain condenser, shut off water supply and disconnect inlet and outlet piping. Remove drain plugs and vent plug.

With condenser heads removed, inspect tubes for refrigerant leaks. (Refer to Carrier Refrigerant Service Techniques Manual.)

Clean condenser tubes with nylon brush (available from Carrier Service Department). Flush water through tubes while cleaning. If hard scale has formed, clean tubes chemically. Do not use brushes that will scrape or scratch tubes.

Because the condenser water circuit is usually an open system, the condenser tubes may be subject to contamination by foreign matter. Local water conditions may cause excessive fouling or pitting of tubes. Condenser tubes, therefore, should be cleaned at least once a year or more often if the water is contaminated.

Proper water treatment can minimize tube fouling and pitting. If such conditions are anticipated, water treatment analysis is recommended. Refer to the Carrier System Design Manual, Part 5, for general water conditioning information.

If hard scale has formed, clean the tubes chemically. Con- sult an experienced and reliable

IMPORTANT: If the ambient temperature is below 32 F during a shutdown period; protect the condenser from freezing by draining the water from the system or by add- ing antifreeze to the water.

10