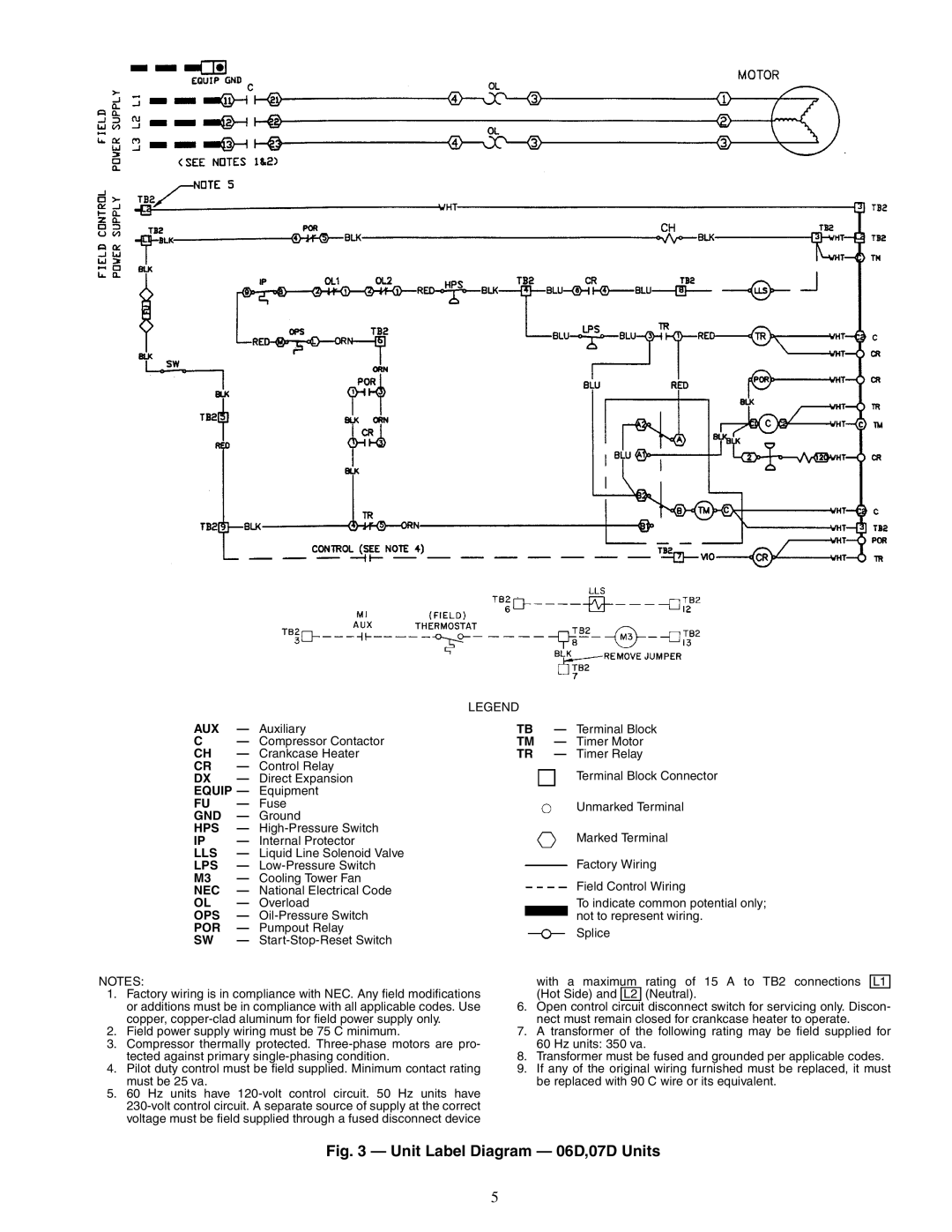

LEGEND

AUX — Auxiliary

C— Compressor Contactor CH — Crankcase Heater CR — Control Relay

DX | — | Direct Expansion |

EQUIP — | Equipment | |

FU | — | Fuse |

GND | — | Ground |

HPS | — | |

IP | — | Internal Protector |

LLS | — | Liquid Line Solenoid Valve |

LPS | — | |

M3 | — | Cooling Tower Fan |

NEC | — | National Electrical Code |

OL | — | Overload |

OPS | — | |

POR | — | Pumpout Relay |

SW | — |

|

NOTES:

1.Factory wiring is in compliance with NEC. Any field modifications or additions must be in compliance with all applicable codes. Use copper,

2.Field power supply wiring must be 75 C minimum.

3.Compressor thermally protected.

4.Pilot duty control must be field supplied. Minimum contact rating must be 25 va.

5.60 Hz units have

TB — Terminal Block

TM — Timer Motor

TR — Timer Relay

Terminal Block Connector

Unmarked Terminal

Marked Terminal

Factory Wiring

Field Control Wiring

To indicate common potential only; not to represent wiring.

Splice

with a maximum rating of 15 A to TB2 connections L1 (Hot Side) and L2 (Neutral).

6.Open control circuit disconnect switch for servicing only. Discon- nect must remain closed for crankcase heater to operate.

7.A transformer of the following rating may be field supplied for 60 Hz units: 350 va.

8.Transformer must be fused and grounded per applicable codes.

9.If any of the original wiring furnished must be replaced, it must be replaced with 90 C wire or its equivalent.

Fig. 3 — Unit Label Diagram — 06D,07D Units

5